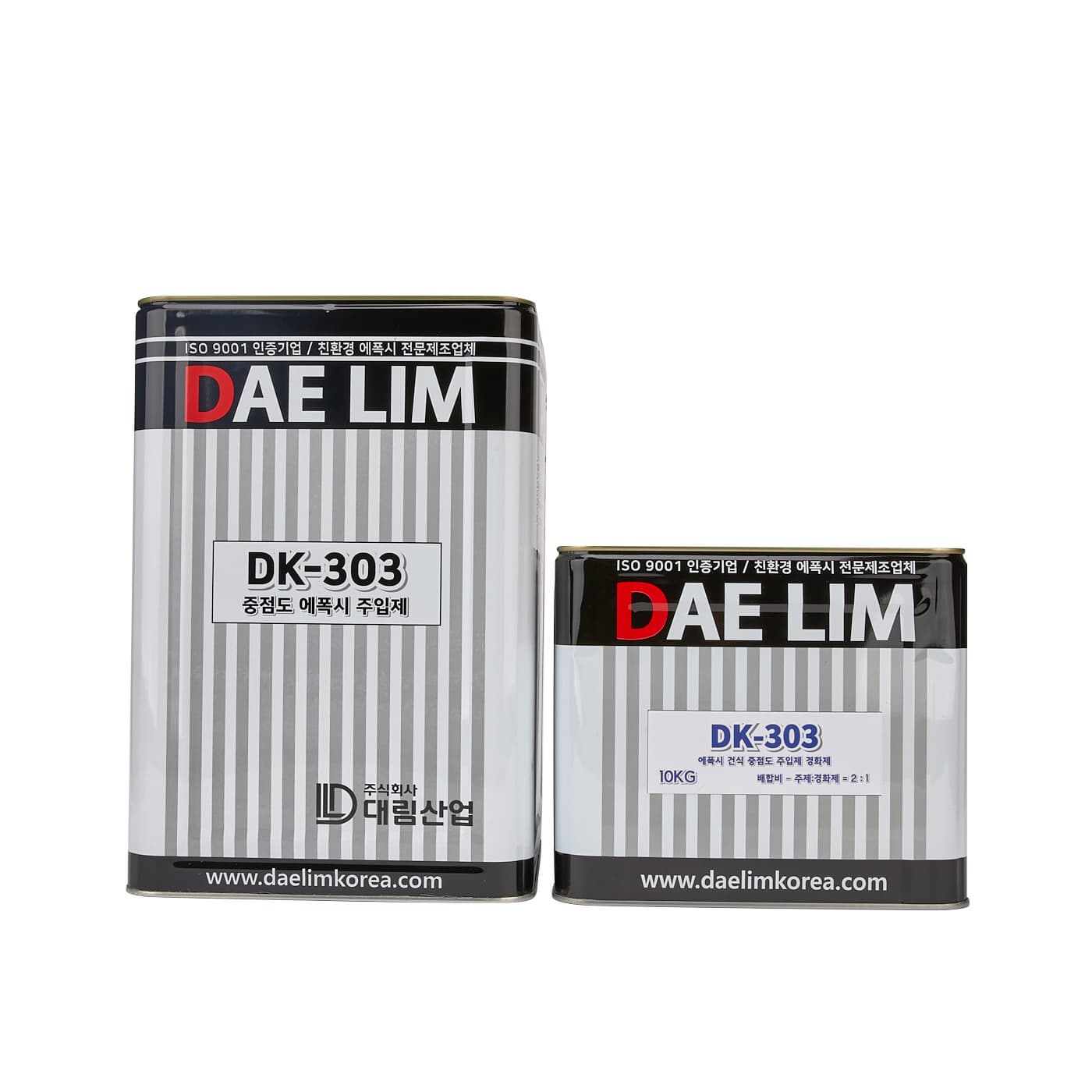

Dry Medium-Viscosity Epoxy Crack Filler

Epoxy Adhensive for multi purpose

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Others,T/T

- Production method

- Available,OEM

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Wall Materials , Tiles & Accessories

Daelim Industry Co.,Ltd.

- Membership

- PRO

- Recent Visit

- Jan 08, 2025

- Country / Year Established

-

South Korea

/

2012

South Korea

/

2012

- Business type

- Others

- Verified Certificate

-

2

| Product name | Dry Medium-Viscosity Epoxy Crack Filler | Certification | - |

|---|---|---|---|

| Category |

Wall Materials

Tiles & Accessories |

Material | - |

| Keyword | epoxy adhesive , tile adhesive , wood adhesive , injection sealants | Unit Size | 231.0 * 231.0 * 346.0 mm |

| Brand name | - | Unit Weigh | 20 kg |

| origin | South Korea | Stock | 2000 |

| Supply type | Available,OEM | HS code | 390730 |

Product Information

- Self-Curing Two-Component Epoxy: DK-303 is a self-curing two-component epoxy that offers excellent adhesion and durability, ensuring stable performance in various environments.

- Room Temperature Curing: This product effectively cures at room temperature and can also be used in low-temperature conditions, providing flexibility for different repair scenarios.

- Enhanced Mechanical Strength: After curing, DK-303 achieves outstanding mechanical strength and chemical resistance, making it ideal for structures subjected to heavy loads—critical for ensuring structural safety.

- Superior Adhesion: With excellent bonding between concrete and steel plates, it effectively reinforces crack areas, maximizing the efficiency of repair work.

- Versatile Repair Applications: Suitable for a wide range of repair projects, including bridges, tunnels, and industrial facilities, and especially effective for medium crack repairs and steel plate reinforcement.

1. Crack Inspection and Method Selection: Inspect the crack area, its condition, width, and depth before construction to determine the appropriate repair method and the viscosity of the injection material.

2.Surface Cleaning: Cleaning the repair area is essential to prevent reduced injection volume and surface adhesion due to contaminants. Remove dirt and dust using brushes and grinders, and clean any grease with solvents such as thinner.

3.Anchor Placement: For concrete thicknesses between 20cm and 30cm and cracks less than 1mm wide, it is standard to install four anchors per meter at 25cm intervals. Adjust the number of anchors based on the structure’s thickness and crack characteristics. For slab reinforcement, it is effective to perform injection work from the lower ceiling of the slab to be reinforced, excluding the bottom surface of the slab. Anchor placement may vary depending on the crack pattern.

4.Anchor Installation: Attach and secure the anchors using epoxy sealant (dry or wet type).

5.Crack Sealing: To prevent leakage of the injected epoxy resin outside the crack area, seal cracks other than those covered by anchors with epoxy sealant (dry or wet type), with a thickness of 1mm and width of 3-5cm. Ensure the sealant is fully cured before proceeding with the injection.

6.Epoxy Injection: Use a low-pressure injector (Micro Capsule) to

inject epoxy into the already installed anchors, skipping one anchor at a time. For uninstalled anchors, set up syringes for injection. If the epoxy resin in the injector cylinder depletes before reaching its curing time, quickly replace the syringe and continue the injection process.

▶For more details, please request the Technical Data Sheet (TDS) or the specifications.

B2B Trade

| Price (FOB) | Negotiable | transportation | Air Transportation,Express,Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Others,T/T | Shipping time | Negotiable |

- President

- OH MIN

- Product Category

- Epoxy Adhesives

- Year Established

- 2012

- Main Markets

-

China

China

Italy

Italy

U.S.A

U.S.A

Viet Nam

Viet Nam

- Factory Information

-

Headquater

- Main Product

Related Products

ACOUSTIC

600 Series - PVC Tile, LVT, Vinyl, Flooring

WOODEN WOOD POLISHED PORCELAIN FLOOR TILE TILES 60x60

Soluble Salt Polished Tile

Sun Shade Net