CE Certified Robotphoenix Fully Automatic Baby Wet Wipe Lidding Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Robotphoenix

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- wet wipe machine, plastic lid applicator, wet wipe application machine, wet wipe lidding machine

- Category

- Paper Product Machines

Robotphoenix LLC

- Verified Certificate

-

7

| Product name | CE Certified Robotphoenix Fully Automatic Baby Wet Wipe Lidding Machine | Certification | - |

|---|---|---|---|

| Category | Paper Product Machines | Ingredients | - |

| Keyword | wet wipe machine , plastic lid applicator , wet wipe application machine , wet wipe lidding machine | Unit Size | 1.4 * 2.4 * 4.3 m |

| Brand name | Robotphoenix | Unit Weigh | 1500 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

CE Certified Robotphoenix Fully Automatic Baby Wet Wipe Lidding Machine

Full-automatic robot arm lid applicator is a perfect combination of industrial DELTA ROBOT and machine visual technology.

Industrial delta robot, with its characterized structure and performance, is designed to realize high speed picking up and putting motion.

Machine vision system can break the constraints of work environment, working hours, production rate and else. It can realize rapid detection of objects shape, size, pattern and their relative position. Visual system can do online monitoring and recognize the position of sticking label on wet wipes package then measuring position and angle.

Robot arm can complete grab lid, spray glue, put lid with high speed in place of labour and repetitive work and apply to various lid shape.

It allows user to reduce the amount of labor, improve production efficiency, accuracy and product quality.

Highly integrated system design, plug and play;

Convenient operation approach for product shift, production changeover within half an hour;

Touch-screen monitor, humanized operating system;

1 worker is all that needs for operation, Manpower saving, up to 3-4 person;

Higher efficiency and product quality;

Reliable vacuum test method for problem alarming and machine self-protection;

Remote control system, for long distance trouble shooting within hours

Life long after-sale service system, 24/7 online technique support.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T | Shipping time | Negotiable |

- President

- Robotphoenix

- Address

- No. 1658 Xingyu Technology Garden, Keyuan Rd. Hi-tech Development Zone, Jinan, PRC

- Product Category

- Other Textile Machinery,Packaging Machines,Paper Processing Machines Parts

- Year Established

- 2012

- No. of Total Employees

- 101-500

- Company introduction

-

Robotphoenix LLC, founded in 2012, is located at Jinan Shandong Province, with branches in Shenzhen and Shanghai. As one of the top Chinese manufacturers of parallel robot, Robotphoenix’s products and services scope span industrial robot R&D and production, automated system integration, vision system development, etc. It’s star product, BAT series parallel robot, is widely applied in food, pharmaceutics, photovoltaic, electronics, daily chemical product and logistics industries for sorting, conveyance, packaging, coating, stacking etc.. With its knowledgeable R&D team and professionals, Robotphoenix is to supply customers with automation solutions and services of high quality and best performance-price ratio. Robotphoenix dedicates itself to creating a trustworthy national automation brand and contributes to the modernization process of Chinese national industry.

- Main Product

Related Products

Cake Cup Making Machine

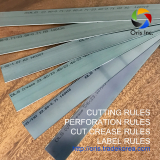

Steel Cutting Rules, Thompson Knife

_2.jpeg)

Cutting Rules(Center Bevel,Long Center Bevel ,Double Bevel.)

MIDAS TRAY

Rotary Feeder

China

China