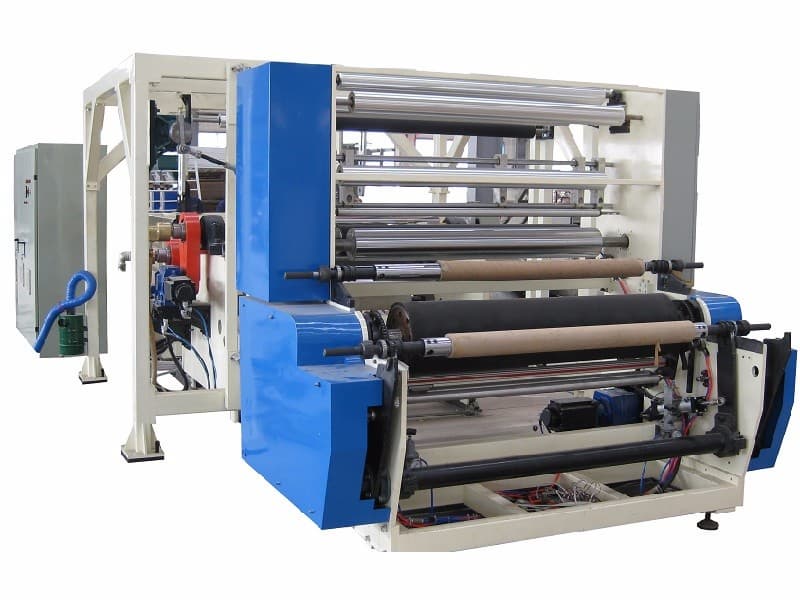

Cast Film Production Line

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- HANDERN

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Laminating Machines

wuhan handern machinery co., ltd

- Verified Certificate

-

7

| Product name | Cast Film Production Line | Certification | - |

|---|---|---|---|

| Category | Laminating Machines | Ingredients | - |

| Keyword | plastic , extrusion , cast film | Unit Size | - |

| Brand name | HANDERN | Unit Weigh | 30000 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Introduction of Cast Film Extrusion Machine:

Cast Film Extrusion Machine can cast PE, PP, EVA, PEVA, TPU films which are widely used for hygiene, medical and packaging applications. Cast film machine have some advantages compared with blown film machine.

Applications of Cast Film Extrusion Machine

- Personal hygiene products: tampons, baby diapers, green scrubs, disposable bed sheet

- Daily necessities: raincoat, gloves, waterproof clothing,raglan sleeve;

- Building products: breathable materials, etc.

- Packaging: computer cover, electric appliance cover, shoes cover, cosmetic soft package, shopping bag, gift bag, document folder, file cover and etc.

Specifications of Cast Film Extrusion Machine

Width of die(mm) | 1600-3000 |

Width of breathable film(mm) | 1200mm-2600mm |

Linear Speed(m/min) | 100-250 |

Width of finished film(mm) | 0.015-0.05 |

Weight of finished film(gsm) | 20-40 |

Maximum Production Capacity(kg/h) | 200-300-400-500-600 |

Installed power(kw) | 380 |

Advantages of Cast Film Extrusion Machine

1.equipped with professional extrusion and recycling system for edge trim online

2.advanced vertical or horizontal stretching unit, convenient and safe to haul off the film;

stretching ratio can be adjusted according to products' requirement;

3.The whole line is controlled by touch screen and PLC, and all kinds of emergency buttons are complete and easy to operate;

4. latest winding tension control unit with stable, reliable, precise measurement.

5.optional online cutting unit and printing unit, it can realize automatic flow operation;

Main Parts of Cast Film Extrusion Machine

1 | Feeding System | One set |

2 | Extruding System | One set |

3 | Hydraulic Pressure Screen Exchanger System | One set |

4 | Melting Pressure and Temperature Sensor | One set |

5 | Die specially for Casting | One set |

6 | Cast forming unit | One set |

7 | Unilateral Stretch unit | One set |

8 | Online thickness gauge | One set |

9 | Online computer detective unit | One set |

10 | Haul off unit | One set |

11 | Embossing unit | One set |

12 | Winding unit | One set |

13 | Control System | One set |

Process of Cast Film Extrusion Machine

Raw material with twin screw granulator making pallet, dry and transfer to the extruder to extrusion, single layer, three layers extrusion, casting forming, then use MDO one direction stretch thermoforming and embossed by embosser, edge cutting, trimming, unit to ensure the full utilization of raw material, finally winding into a roll. The water proof breathable film products with silky feel.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Emma

- Address

- NO.61 yinbo road jinhe,dongxihu district Wuhan City

- Product Category

- Plastic Product Making Machinery

- Year Established

- 1989

- No. of Total Employees

- 101-500

- Company introduction

-

Wuhan Handern Machinery Co., Ltd, is located in the Jinghe Industrial Park of Dongxihu District, Wuhan City, Hubei Province in China and covers an area of 35,000 square meters, very near to the airport, railway station, and bus station.Harden, established in 1989, is a sino-joint venture high-tech enterprise, specialized in plastic machinery R&D and manufacturing with over 30 superior technical talents and skillful trained operators. Our products are widely applied to electronics,packaging, machinery, light industry etc.Our company passed the ISO 9001-2008 international quality system certification and all products have acquired CE certificate of EU. for years. Also, we have gained a sery of achievements, such as international leading technology of hollow profile sheet extrusion line producing, solar cell films extrusion line series production and other technilogy patents.With the advantage of abundant capital background, excellent technology talents, plurality of manufacturing management experience and skillful precision mould manufacturing experience, our products are very popular in domestic market and have been exported to over twenties countries including UK, Japan, Canada,etc.We always promise the best product and support and spare no efforts to provide the best product and the most professional technical support and training for our customers.Corporate CultureContinuous improvement and innovation; pursuit perfect quality; honest business; creating value for customersJust give us your ideas and allow us do the best!

- Main Product

Related Products

Hot Stamping Foil for Plastic Substrates

Veinas EPE/EPP/EVA/XPE foam Bonding Machine: hot air

Heavy Duty Pouch Laminator TOFO SpeedR10

CFRP air shaft

Heavy Duty Roll Laminator TOFO 720

China

China