HAST PCT high-low temperature test chamber with pressure high pressure accelerated aging testing chamber factory High Accelerated Stress Test

Steam Aging Test Chamber

Ozone Aging Chamber

Chamber/HAST Chamber

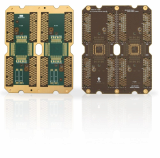

It test the resistance to pressure and air tightness for circuit board, multi-layer circuit board, IC, LCD and magnet iron. This machine is one of the common machine in aging equipment, used to test various types of materials for their performance under the condition of high temperature and high pressure. Application: Quality inspection for all types of electronic products, electric appliance, and products from communication, instrument, metal, plastic, automobile, food, chemical, building materials, medical and aerospace industries.

Pressure Accelerated Aging Test Chamber (HAST)

Safety Device high pressure accelerated aging testing chamber factory:

1. Safety device for the pot: If the inner box is not closed , the machine can not start

2. Safety Valve: When the inner box's pressure higher than the machine's undertake value, it will self-relieve.

3. Double overheat protection device: When inner box's temperature is too high, it will alarm, and Automatic cut off

the heating power.

4. Cover protection: The inner box's cover is made of aluminum alloy, can protect the worker from scald.

Technical Parameters of high pressure accelerated aging testing chamber factory:

Model GHAST- 25 GHAST- 35 GHAST- 45 GHAST- 55 GHAST- 65

Equipment Capacity(L) 17 43 87 155 250

Internal Dimension:Φ×D (mm) 300*250 350*450 450*550 550*650 650*750

External Dimension

Φ×D (mm) 850*1300*900 900*1350*900 1000*1480*1000 1150*1650*1200 1300*1800*1350

Steam Temperature Range Steam Temperature Range: 100°C~135°C, (143°C is optional)

Relative Pressure/

Absolute Pressure Relative pressure: display values indicated on the pressure gauge

Absolute pressure: Value that add 100 Kpa based on display values indicated on the

pressure gauge (The actual value in the inner box)

Steam Humidity 70~100%R.H. steam humidity adjustable

Steam Pressure(Absolute Pressure) 101.3Kpa +0.0Kg/cm2~2.0Kg/cm2 ; (3.0Kg/cm2 is special standard)

Recursive Device Steam in forced-circulation

Safety Protective

Devise Water short storage protect, over pressure protect.(have automatically/manual water replenishing, automatically discharge pressure function )

Accessories Two layers stainless steel plate

Powder AC220V, 1ph 3 Lines ,50/60HZ; AC380V ,3 ph 5 Lines,50/60HZ

Customized service Welcome to Non-standard,Specail requirements,OEM/ODM orders.

The technical information will be subjected to change without notice

Features about high pressure accelerated aging testing chamber factory:

1.Automatic adding water function, and automatic filling water upon the water short storage while testing.

2.Automatic operation to test process finished, easy to use.

3.Temperature control: LED digital temperature controller can make accurate testing of temperature setting, control and

display.

4. LED digital timer, when the inner box's temperature reached the setting value, then start to time to ensure the test

complete.

5.Accurate pressure: temperature chart always shows the inner box's pressure and relative humidity.

6.Water device is automatically discharge not saturated steam in order to achieve the best steam quality.

7.A integrated silica gel door gasket, air tightness is very good, and long operation life.

8.The inner box is mirror-polished , graceful and non-pollution

HAST - Highly Accelerated Stress Test Chambers

Designed for consistant, repeatable results

HAST (Highly Accelerated Stress Test) chambers reduce the time it takes to complete humidity testing for semiconductors. By elevating temperatures above 100°C and increasing the pressure, simulation of normal humidity tests can be made while maintaining the same failure mechanisms. Tests can be completed in days, not weeks. Our HAST systems have a modern design that's easier to use:

Automatic humidity filling

Automatic door lock

A more square workspace, allowing more product to be loaded

Convenient, hermetic power-pin system for bias testing

We now offer a hermetic port connection to allow special signal lines like coax or fiberoptics to be run into the chamber. You can use hermetic port plugs like those from Buffalo Conax with this port system.

Features

OPERATION FEATURES:

Unsaturated or saturated humidity control

Multi-mode System (wet bulb/dry bulb) controls humidity, even during heat-up and cool-down. Fully conforms to EIA/JEDEC Test Method A110 & 102C.

Programmable controller with temperature, humidity, and count-down display. Stores up to 10 test profiles, with 30 steps per profile.

12 Specimen power terminals, allows power-up of specimens (12 per workspace on "double" units)

Two feed-through ports, each 0.75" NPT (standard on units sold in North America only)

Automatic fill of the humidity water at the start of a test (except TPC)

CABINET FEATURES:

Inner cylinder and door shield protect specimens from dew condensation

Interior is shaped more like a square for easier product loading (TPC model is cylindrical)

Two stainless steel shelves

Set of casters for easy movement of the chamber (except double-stacked models)

Push button door lock (except TPC)

Bottom of the unit allows storage space for peripheral equipment

SAFETY FEATURES:

Overheat & over-pressure protectors

Door lock safety mechanism to prevent opening of the door while the chamber is pressurized

Specimen power control terminal: shuts down the product power in the event of an alarm

Armenia

Armenia

Austria

Austria

Bahrain

Bahrain

Bosnia-Herzegov

Bosnia-Herzegov

Brunei

Brunei

China

China

India

India

Iran

Iran

Kazakhstan

Kazakhstan

Kuwait

Kuwait

_2.jpg)