contamination molds & dies cleaning system

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- molds, fludized bed, dies cleanung

- Category

- Other Machinery Parts

YJSTECH LTD.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | contamination molds & dies cleaning system | Certification | - |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | molds , fludized bed , dies cleanung | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 847989209 |

Product Information

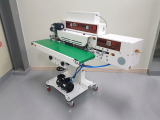

Industrial Fluidized Bed Cleaning System

Since the advent of plastic, it has been difficult to remove polymeric residues, powder coatings, oil contaminations and other organic materials from metal parts and extruder hardware. Existing cleaning methods in industry need a lot of money and labor force, and bring about material loss and environmental pollution. Industrial Fluidized Bed Cleaning System is the primary option to solve the problems. The system will provide significant benefits for customers

What is FLUIDIZED BED

“Fluidized Bed” is a bed which is in a state of fluidization. The state of fluidization is achieved when the individual particles of solids become microscopically separated from each other by the moving gas. This “fluidized bed” of particles has unusual properties which differ markedly from either those of the gas or of the solid particles. Instead, the fluidized bed behaves remarkably like a liquid state. A unique characteristic of fluidized particles is the relatively high rate of heat transfer which yields highly isothermal conditions, as well as excellent heat transfer to solid surfaces.

The combination of excellent heat transfer characteristics and high heat capacity are ideal for attaining rapid stabilization at an isothermal condition.

Because of properties of a fluidized bed, it is possible to control temperature easily in the chamber and to shorten one cleaning process time.

Principle of operation

A fluidized chamber, filled with Thermal Medium, is heated to proper temperatures (400~500℃) and compressed air from Air Supply passes up in the chamber at the same time. Heating and air flow make a loosed packed mass of solid particles(Thermal Medium) into “fluidized bed” of particles. The fluidized bed removes residues from metal parts and extruder hardware within 30 minutes. During cleaning items, the fluidized chamber may emit fumes. But a fume extraction system in Industrial Fluidized Bed Cleaning System eliminates fumes during the burning process.

*Thermal Medium is non-corrosive and non-abrasive and there is the additional benefic that it does not solidify when cooled, making the chamber easy to start up from room temperature. The medium can be recycled many times after one cleaning process.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Lee, shinhyung

- Address

- 64-4, Pulmugol-ro, Paju-si, Gyeonggi-do, Korea

- Product Category

- Cleaning Equipment & Parts,Washing Machines

- Company introduction

-

Fluid Cleaning System

- Factory Information

-

YJSTECH CO., LTD

- Main Product

Related Products

vacuum band-cylinder

Wrapping Scale machine

Vagcom 17.1.3 ATMEGA162 VCDS 17.1.3 China crack VAG 17.13 Fo

RC Level Rod

180 degree rotation brushless servo XQ-S5650D