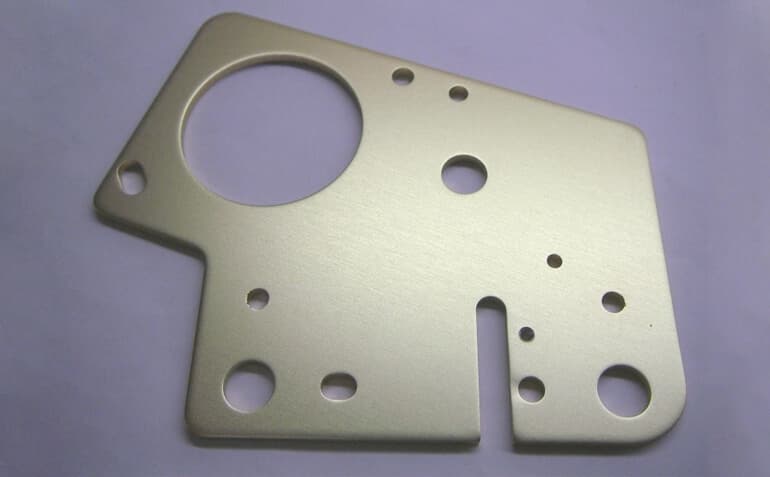

Stamping Parts STA001

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Taiwan

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- stamping parts

- Category

- Other Machinery Parts

DFK Industrial Corp.

- Verified Certificate

-

7

| Product name | Stamping Parts STA001 | Certification | - |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | stamping parts | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Taiwan | Stock | - |

| Supply type | - | HS code | - |

Product Information

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- na

- Address

- No.33, Ln. 3, Sec. 1, Zhongzheng E. Rd,Tamsui Dist., New Taipei City, Taiwan 25147

- Product Category

- Other Machinery & Industry Equipment

- Year Established

- 1988

- Company introduction

-

"With more than 25 years in the field of CNC manufacturing process, DFK Industrial Corp. is a manufacturer of precision machined parts with efficient Japanese CNC automatic compound lathe and milling machine center.We offer OEM/ODM/Assembly services and the application of our products: Optical Fiber connectors; Sensors housing, Medical parts, Telecom components, Hydraulic & Pneumatic parts, Mechanical elements, Motor accessories, Automobile parts.We are full of experience on processing various kinds of materials like brass, aluminum, steel, stainless steel and plastics. Our production range of diameter is from 1mm to 65mm on turning parts; for milling part is max. 1.5 m. Different Surface treatments are also available.With ISO 9001 certificated quality system to control every procedure, we pursue to achieve quality manual, exceed the satisfaction of customer as our quality policy, and delivery on schedule.To implement new technology, invest in automatic production equipments, develop state-of-art products, focus on quality and cost, meet customer needs and offer worldwide service are our business strategies.We like to use the Multi-purpose Processing Machine to perform tasks like drilling, milling and grooving with high-speed material feeding, speedy blade changing at the turret, potential installation of a fourth axis and a rotating platform."

- Main Product

Related Products

MECHANICAL PACKING, GLAND PACKING, YARN ROPE PACKING

FR Coating

yacht fittings

Date Pin (Date Core)

vacuum band-cylinder

Taiwan

Taiwan