Ball mill girth gear manufacture 1-150T

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- CHAENG

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery Parts

Xinxiang Great Wall Steel Casting (CHAENG)

- Verified Certificate

-

8

| Product name | Ball mill girth gear manufacture 1-150T | Certification | - |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | ball mill girth gear , ball mill gear , ball ring gear , girth gear manufacturer | Unit Size | - |

| Brand name | CHAENG | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

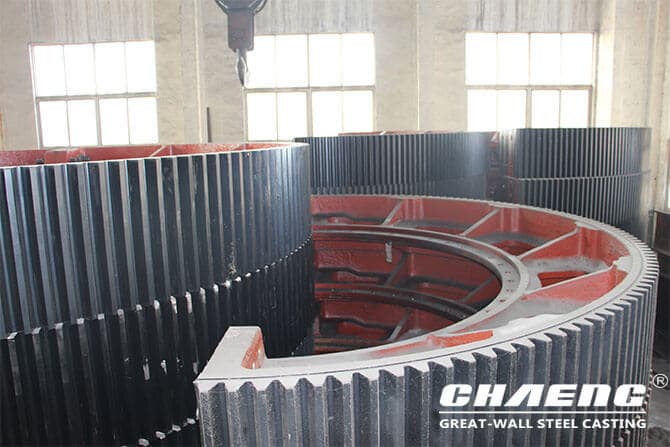

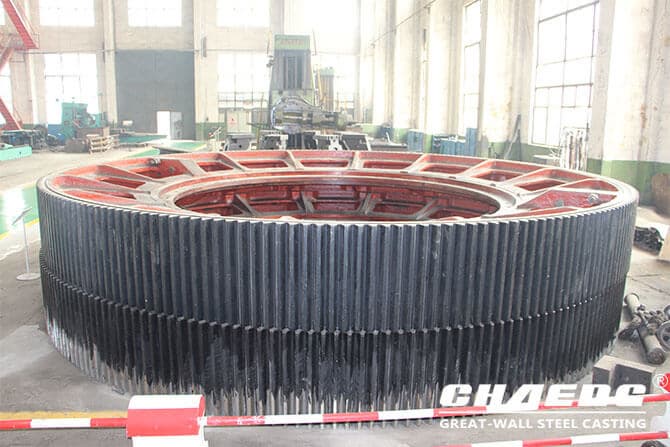

CHAENG can supply large girth gear as:

Weight: 10~35T

Diameter: 2m-14m

Material: Cast steel

Applicable devices: Rotary kiln, ball mill

Application: Cement, building material, metallurgy etc.

Customizable or not: Yes, according to your drawings

Girth gear, also called gear ring or gear wheel is large diameter internal ring gears for heavy duty equipment. CHAENG (Great Wall Steel Casting) provides customised girth gear for ball mill and rotary kiln according to customers' drawings.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Mr Wang Jizhong

- Address

- Mengzhuang Town, Huixian City, Henan Province, China

- Product Category

- Cast & Forged,Other Machinery Parts

- Year Established

- 2007

- No. of Total Employees

- 501-1000

- Company introduction

-

<p>

Xinxiang Great Wall Steel Casting Co,Ltd (CHAENG), located at National Sustainable Development Experience Area, Mengzhuang Town, Huixian City, Henan Province, is an integrated foundry enterprise which involves in research, manufacturing, processing and assembly. We can provide custom manufacturing services of large steel castings referring to materials of carbon steel, alloy steel, high alloy steel series (1-150T per piece) for customers, covering building materials machinery, metallurgy industry, water conservancy project, chemical industry, forging equipment, ceramic industry, heavy machinery, ship parts, etc.

CHAENG has φ8m heavy double-column vertical lathe, φ6.3 m vertical lathe and φ8m gear hobbing machine imported from Russian, Czech T6920 landing boring-milling machine and domestic TX220 floor type boring-milling machine, 6625Y (2.5m × 8.0m) gantry milling machine imported from Russia, domestic 120 × 3000 heavy CNC Universal Machine, and other processing equipment. CHAENG also introduced from Germany OBLF company the GS1000 vacuum direct reading spectrometer, high-speed carbon and sulfur analyzer, the three elements of the high-speed computer analyzer, digital ultrasonic flaw detector, multi-purpose magnetic detectors and other physical and chemical testing facilities, leveraged universal strength testing machine, hammer system prototype and other tensile testing equipment. Using CAE software for digital simulation in the casting process, improves the casting technique to a new level. Finished castings uses arc gouging, CO2 gas shielded arc welding, blasting and other technology, which ensures the appearance quality of steel castings and forms a complete system of casting production base.

With the equipment advantage and access to export and import, we are dedicated to provide our customers with high quality product, reasonable price and great service, sincerely to build a long-term cooperation and achieve win-win and common development. CHAENG steel castings are very popular both in domestic and abroad,which has been exported to 25 countries, for example, Japan, Korea, Russia, Italy, Turkey, etc.

- Main Product

China

China