FULL AUTOMATIC SUGAR CUBE MACHINE 50 TONS / DAY

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Turkey

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

GoldPak Makina

- Verified Certificate

-

8

| Product name | FULL AUTOMATIC SUGAR CUBE MACHINE 50 TONS / DAY | Certification | - |

|---|---|---|---|

| Category | Fruit & Vegetable Processing Machines | Ingredients | - |

| Keyword | sugar , cube | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Turkey | Stock | - |

| Supply type | - | HS code | - |

Product Information

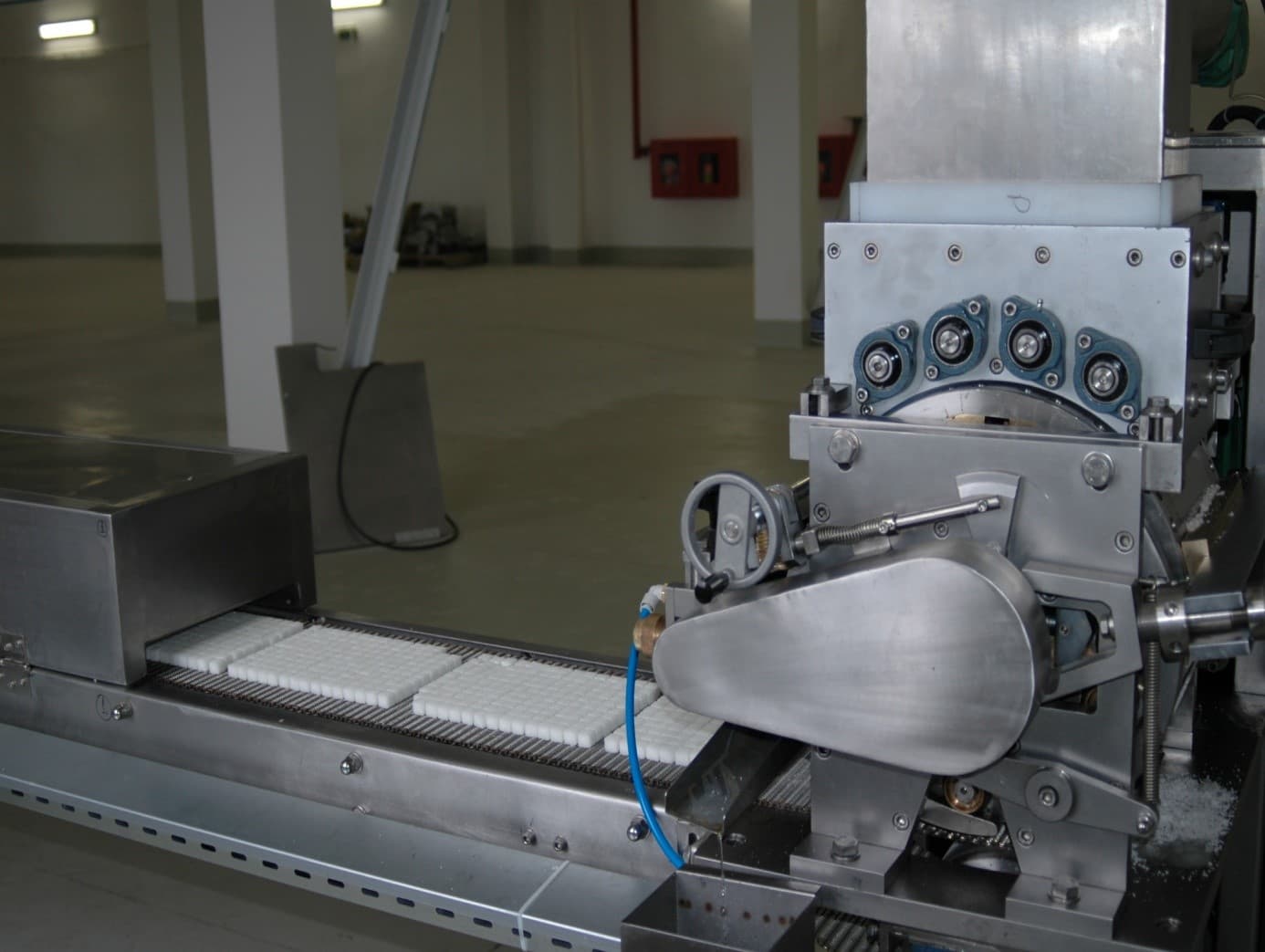

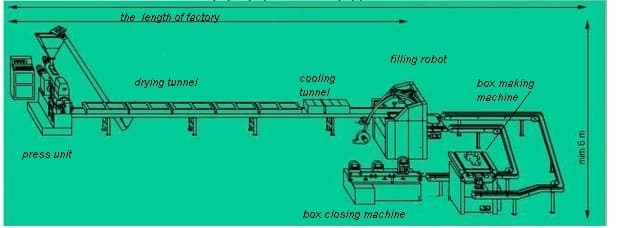

PLC Control, comfortable use and easy menu, press sugar watching camera, on screen reporting, production capacity counting and it has some special fonctions like this. Gold Paketleme Makina Gıda San. ve Dış Tic. A.Ş is producing the RG450 full automatic sugar cube machine which has a capacity of 50 tons / day with the automatic spiral system over 10 years experience. It is equipped with drying oven which makes feeding with automatic spiral system. The crystal granulated sugar, which comes to the silo section by means of the spiral, is moistened and transferred to the barbotin section with the help of dosing pump. The basis weight settings can be configured according to the preferred sizes and needs of consumers.

The sugar cubes which get out from the press section, are transferred on the chrome-nickel matting band serially. The sugar cubes, proceeding on the matting band, are dried by means of the infrared resistances, then transferred to the cooling section. In this section, the sugar cubes are cooled with the cooling fans and the ideal/optimal sugar cube form is obtained. The ideal sugar cubes are ranged by means of the filling robot according to the dimensions of the box and filled in the ready-made boxes which come from the packing box in 2-3-4 serials and vacuumed with the system which provides negative pressure. The graphically designed boxes which get out from the press with the requested dimensions, are placed into the magazine section of the box making machine as 500 or 1000 pcs. They are taken by the greasy vacuum and pasted from 4 sides and turn into boxes, then these boxes are left on the conveyor band in order, to go to the pack filling robot.

For increasing the sugar quality and decreasing the glue cost in a equipment of 25 tons, the negative pressure providing vacuum system can be added, for cleaning the brush water in press section according to the consumer requests. At the same time, the pneumatic system can be added to the drying ovens to open and close automatically and for bringing down the cost of glue, locked-box system can be made to the box-making section. For the automatic packing of sugar cubes, pack opening, pack filling and pack closing machines can be added to the output of the box closing section.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Tamer Ozmen

- Address

- Ankara Turkey

- Product Category

- Fruit & Vegetable Processing Machines

- Year Established

- 2005

- No. of Total Employees

- 51-100

- Company introduction

-

<p>

As Goldpak Packaging Machinery Food Industry And Trade Company we are manufacturing fully automatic cube sugar packaging line, a single cube sugar wrapping machine, stick candy machine, digital scales fully automatic packaging machines, since our founding We make sugar cubes and granular products packaging in different sizes and packaging machines .

Our company can provide maximum performance in quality and capacity of the close experience with technological developments to follow every day creating new technological products, machinery consists of many years, especially regarding sugar cubes machines since 2005.

Our company is producing with specialist staff, technical staff, skilled service team, modern machinery and a leading product in the world (Pneumatic in Festo, Eaton-Moeller in electrical materials, bearings are SKF-FAG ASIO304 Chrome nickel metal canopy, Eregli in the Sheet Metal Components ST37 and ST52, 4140 in steel products , WOLTE the motor products, product IE in Gear) at İvedik O.S.B Ankara facilities in Turkey. Every step of production is making production using in its own site.

- Main Product

Related Products

Scallion Shredder

HDM Icecream Wafer Machine

HDM Pancake machine

Auto donuts machine(MR-9900)

Rice cake popping machine_K-Pop rice pop machine

Turkey

Turkey