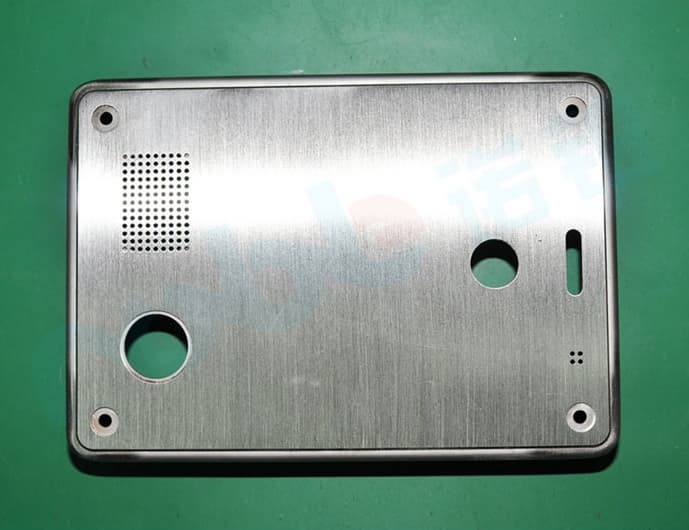

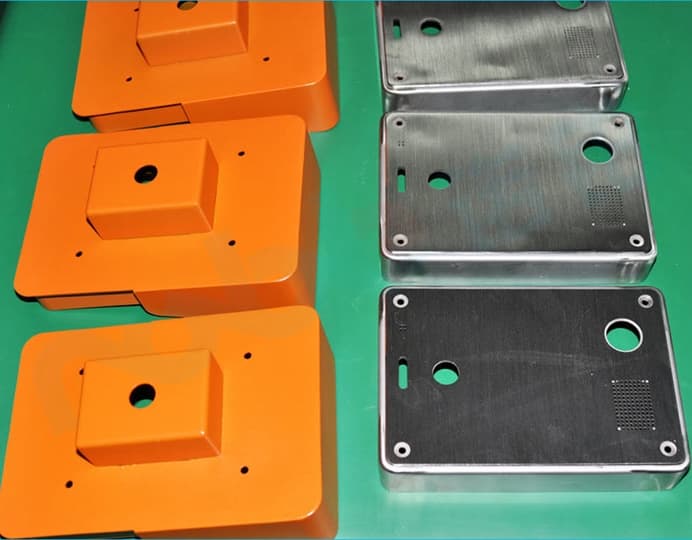

SheetMetal automation equipment shell

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Plastic & Rubber Machinery Parts

Shenzhen Noble Smart Manufacturing Tech. Co., LTD.

- Verified Certificate

-

8

| Product name | SheetMetal automation equipment shell | Certification | - |

|---|---|---|---|

| Category | Plastic & Rubber Machinery Parts | Ingredients | - |

| Keyword | sheet metal , sheet metal parts , al alloy , automation equipment shell | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

|

Project Quick details |

|

Parts

applications: |

Protect

the appearance |

|

Material:

|

Aluminum

alloy 5052, etc. |

|

Manufacturing

Process: |

Sheet

metal, welding |

|

Finish

Treatment: |

wiredrawing,

baking finish, laser carving |

|

Difficulties

& Highlights: |

High

precision |

|

Size |

Customer’s 3D/2D drawing |

|

Brand

name |

Noble |

|

Palace

of origin |

|

Automation

or automatic control, is the use of various control systems for operating

equipment such as machinery, processes in factories, boilers and heat treating

ovens, switching on telephone networks, steering and stabilization of ships,

aircraft and other applications and vehicles with minimal or reduced human

intervention, with some processes have been completely automated.

Automation

has been achieved by various means including mechanical, hydraulic, pneumatic,

electrical, electronic devices and computers, usually in combination.

Complicated systems, such as modern factories, airplanes and ships typically

use all these combined techniques. The benefit of automation include labor

savings, savings in electricity costs, savings in material costs, and

improvements to quality, accuracy and precision.

The term

automation, inspired by the earlier word automatic (coming from automaton), was

not widely used before 1947, when Ford established an automation department.it

was during this time that industry was rapidly adopting feedback controllers,

which were introduced in the 1930s.

|

What can we do? |

|

Production Flow: |

Fatigue of aluminum alloy

The

improvement in tensile strength is not always accompanied with increased

fatigue strength in non-ferrous alloys.

The more

an alloy is dependent upon precipitation-hardening for its tensile strength,

the lower its fatigue ratio (endurance limit: tensile strength) becomes.

Age-hardened

aluminum alloys possess disappointing fatigue properties due to localized

straining of precipitates under cyclic stressing, →Improved by more uniformly dispersed

precipitates to prevent coarse slips formation.

An

increase in dislocation density by themomechanical processing helps to improve

fatigue performance, fig.

Effect of TMP on fatigue performance

Note:

duplex structure is required where fine particles to yield high tensile

strength and coarse particles (producing dispersed dislocations) to improve

fatigue strength.

|

Our Equipment |

We take the CNC machining as core technology, meanwhile,

we integrate other upstream and downstream resources in our industrial

chain to provide service for the customer.

We have 4 five-axis CNC, more than 30 high-speed CNC machining centers, CNC

lathes, CNC carved machines, in total we have more than 50 machining equipment.

We are able to provide machining service of CNC milling, turning, engraving, cutting, tapping, drilling, etc.

|

Quality control & After-sale service |

Quality control:

We will provide all documents as you need

such as inspection report, material report, etc. To meet your quality requirements

of products and parts.

After-sale service:

If the parts have any quality problems when you got them, no

matter it happened when we made them or caused by the delivery, we will try

best to help you to solve the problems and take our part of responsibility, so

you will be free from worries.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Wuhua Chen

- Address

- Building B1, Dongfang Jianfu Dayang Industrial Park, Furui Road, Fuyong, Bao`an District, Shenzhen, Guangdong, China

- Product Category

- Other Metal & Metallurgy Machinery

- Year Established

- 2012

- No. of Total Employees

- 51-100

- Company introduction

-

we are a professional manufacturer:

1. Robot structure parts, We provide professional services of structural design optimization and parts machining;

We have perfect ability in manufacturing various types of structural parts made of metal, like aluminum alloy, stainless steel, copper, and so on.

2. Nursing/care devices: we can design and produce nursing/care devices for you.

3. Nursing/care robots: we have accumulated rich experience in the service-robots field that including climbing-stairs robots, rehabilitation robots and intelligent robot seats, etc. we can help customers to develop and produce the whole product.

- Main Markets

-

U.S.A

U.S.A

- Main Product

Related Products

Horizontal foam cutting Machine

Silicone Rubber Braided Pipe Hose Extruder Making Machine

LSR Dosing unit

Quick Mold Clamping system

CCV line for the Power cable

China

China