Hand chamfer, grinder, bevel

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

MIR machine

- Verified Certificate

-

8

| Product name | Hand chamfer, grinder, bevel | Certification | - |

|---|---|---|---|

| Category |

Metal & Metallurgy Machinery

Machinery Tools Other Metal & Metallurgy Machinery |

Ingredients | - |

| Keyword | bevel , grinder , tool , chamfer | Unit Size | 7.0 * 130.0 * 305.0 mm |

| Brand name | - | Unit Weigh | 2 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8466 |

Product Information

ALL-PURPOSE CHAMFER

"Smooth beveling can be conducted for any steel materials with robust cutting."

※Product Features

1. Smooth beveling can be conducted for any steel materials with robust cutting.

2. Repair becomes easier with simplification of components.

3. No extra tool is necessary to control bevel volume.

4. With simple hand movement, you can feasibly control your desired bevel volume.

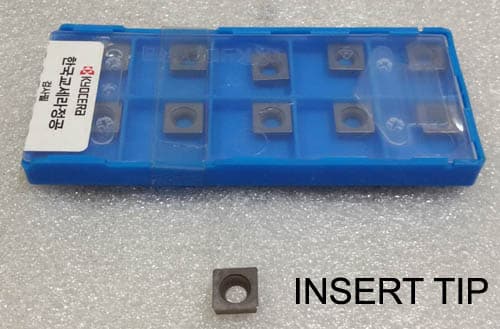

5. You can easily purchase the tip (insert) for cutting in the market.

- The selection of various inserts is possible, depending on the basic material.

Our company does not produce finished products.

Our company produces only Chamfer head and uses it on an existing Hitachi grinder body.

Therefore, only Chamfer head does not sell separately.

Mode of use: Hitachi grinder body + Our chamfer head

Bevel volume is increased / decreased by the 0.5mm, and hamfering up to max 3mm is possible. (0.5~3mm)

※Application Model: Bosch Model No. GWS 7-100 ET + HEAD

220V~60Hz, 3.3A, 720W

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- KIM KANG SEOK

- Address

- 102-21,Sinbok-ro,Deokjin-gu,Jeonju-si,Jeollabuk-do,Korea

- Product Category

- Machinery Tools

- Year Established

- 1998

- No. of Total Employees

- 1-50

- Company introduction

-

[ MIR machine (South Korea) ]

※Major products: Metal processing , Tool holder, Chamfering

1. A precision parts processor.

2. Provide perfect designs and optimal solutions.

3. Prime quality control and sharp observance of delivery date.

4. A company meets customer needs open-minded approach.Tool holder(L, M, S size)

1. The industry's first in·out holder, U-DRILL hanger use.

2. Mount the processing tools effectively and easy to use (MCT/CNC)

3. Possible to increase/decrease the capacity of the tool to the needs

4. Designed to be used in the same frame

5. Space utilization (use a small space)

6. Hole size can be changed to fit the size of the tool (MCT/CNC)

7. Non-drawer open type (Time-saving / Ensure visibility due to the sloping / Easy to remove impurities)●Size: W580.0 * D500.0 * H1650(L size), H1220(M size), H880(S size) mm

●Material: Steel sheet, Powder coating

●Weight: 50kg

- Main Product

South Korea

South Korea