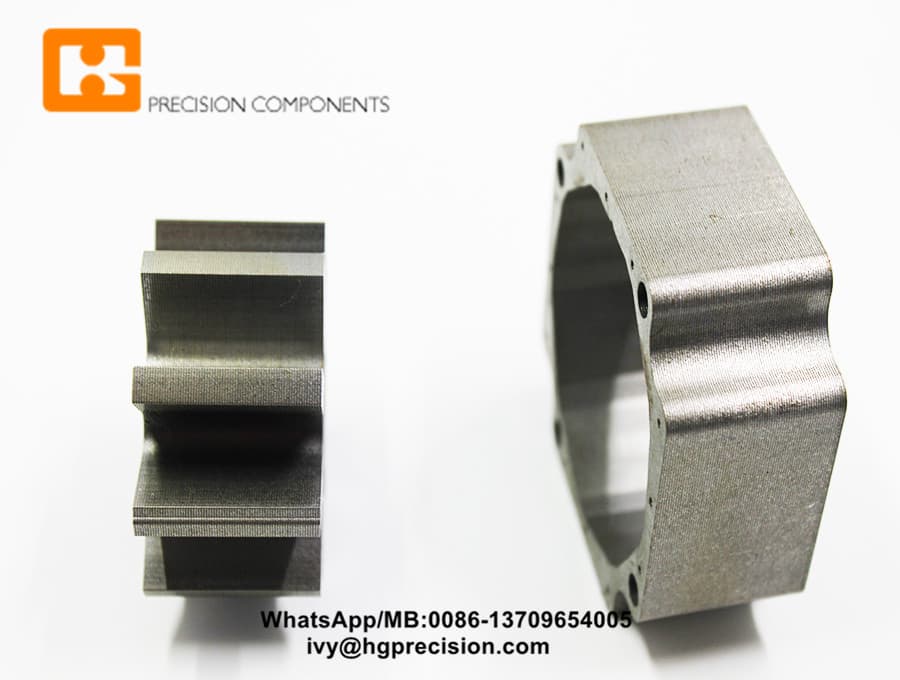

Hard Alloy Stamping Die

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- HG Precison(www.hg-jingmi.com)

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- motor core die, tungsten carbide progressive die, lamination core die, automotive parts stamping mold

- Category

- Molds

HG Precision Components Co., Ltd.

- Verified Certificate

-

8

| Product name | Hard Alloy Stamping Die | Certification | - |

|---|---|---|---|

| Category | Molds | Ingredients | - |

| Keyword | motor core die , tungsten carbide progressive die , lamination core die , automotive parts stamping mold | Unit Size | 0.0 * 0.0 * 2000.0 mm |

| Brand name | HG Precison(www.hg-jingmi.com) | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

We are ISO9001: 2008 certificated factory.

*Stamping Material: Cold rolled steel, galvanized

steel, copper C5210, aluminium, stainless steel 303/304, bronze,

*Material for Die component: A2, D2, CPMM2 or

others as requests:

*In-house die designing: Auto CAD, UG, Auto form,

Master CAM, PRO/E, Solid Works;

*In-House Machinery: Use MITSUBISHI EDM machines

& CNC machining centers to construct die components.

*Precision measuring instruments: 3D CMM,

durometer meter, projector, altimeter and microscope, etc.

*Exporting to: USA, Germany, Spain, Japan, Thailand,

Singapore, etc.

|

Stamping Die |

|

|

Design |

According to different requirement of our customers, we

adopt 2D, 3D and other analyzing software. The design team uses mould design

software, such as CAD, UG(NX), CATIA, SOLIDWORKS and Pro/E, to develop the

mould for the customers based on their specific demands. |

|

Manufacturing |

Equipment: High-speed Machining Center, EDM, WEDM, Grinding

Machine and Punching Machine, etc. |

|

Raw Materials: Mould Steel, such as SKD11, D2, SKD51, SKD61

or Cr12MoV, etc. |

|

|

Standard Parts: MISUMI, PUNCH, DME and many others. |

|

|

Project Period: It varies from 25 to 100 days according to

different products. |

|

|

Quality Warranty: Can be used for 500 thousands to 1

million cycles, according to customer’s demands. |

|

|

Quality Control |

Our company possesses coordinate measuring machine, profile

projector, tool maker microscope, micrometer and many other professional

testing equipment. With them, strict quality control has been carried out. |

|

International Certification |

Certifications of ISO9001, ISO14000 and ISO18000 |

|

Packaging & Shipping |

Wooden Package |

|

After-sales Service |

Our goal is to achieve 100% satisfaction of our customers.

Our service team will provide professional technical support and maintenance

training. From the beginning to the end, customers are always our first

priority. We are looking forward to cooperate with you in the near future |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Sales Manager

- Address

- Shunde District Foshan City, Guangdong Province

- Product Category

- Molds

- Year Established

- 1995

- No. of Total Employees

- 51-100

- Company introduction

-

<p>

Established in 1995, HG Precision Components manufacturing company is specialized in designing and manufacturing stamping dies and metal stamping parts. We export progressive dies, transfer dies, station dies, drawing dies and FPC punching dies to many customers all over the world.

With 6800 square meters facility and 100 employees, we have a professional team consisting of more than 20 experienced engineers and sophisticated tooling technicians who are experted in tooling and stamping. Supported with design software like Auto CAD, UG, Autoform, Master CAM, PRO/E, Solid Works, combined to precision machines like Sodick Wire EDM. It provided adequate condition to guarantee tooling/parts precision and performance.

Our products are well-acknowledged by buyers mainly from Europe, North America and East Asia. They are widely applied in industries such as automotive(Chassis system, Seating and Door System, Audio systems, Cooling system); Home appliances(TV sets, cameras, air conditioners, DVD players); Telecommunication(Antenna base, brackets, enclosures ); Fire-fighting equipment(holding plates); Also in-office equipment like computers, copiers and printers.

With full implementation of ISO9001: 2008 Management System in production management, replying on our advanced inspection equipment like 3D, profile projectors, height gauges, hardness meters, together with our strict quality control systems, HG is dedicate to create endless value for all our clients. Choose HG, you will earn a faithful and helpful partner on our business, you will never regret your choice!

- Main Markets

-

India

India

- Main Product

Related Products

Ball point pen mould

Plastic injection mold Die casting

Liquid Silicone Rubber mould, LSR mould, LSR moulding

Sand Mold

Mold for medical item

China

China