Forged Steel Grinding Balls For Large Mine Mills

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Shandong Iraeta

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Cast & Forged

Shandong Iraeta Grinding Steel Ball

- Verified Certificate

-

9

| Product name | Forged Steel Grinding Balls For Large Mine Mills | Certification | - |

|---|---|---|---|

| Category | Cast & Forged | Ingredients | - |

| Keyword | grinding ball , grinding steel ball , steel grinding ball , grinding media steel ball | Unit Size | 1.0 * 1.0 * 1.0 m |

| Brand name | Shandong Iraeta | Unit Weigh | 1000 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

1 ) Product feature

1 > High Hardness: Surface hardness: HRC57-67 HRC, volume hardness HRC56-64.

2 > High Impact Toughness: The impact toughness of our grinding balls is more than 12 J / cm2.

3 > Low Broken Rate: the actual broken rate is not higher than 1%.

4 > Good wear-resistant and lower wear rate.

Model Number | Material | C% | Si% | Mn% | P% | S% | Cr% | Ni% | CU% | Mo% | Al% | V% |

Iraeta1 | B2 | 0.76-0.82 | 0.17-0.35 | 0.72-0.80 | <=0.020 | <=0.015 | 0.50-0.60 | <=0.25 | <=0.20 | / | 0.020-0.050 | / |

Iraeta2 | B2-1 | 0.77-0.81 | 0.26-0.34 | 0.72-0.80 | <=0.020 | <=0.015 | 0.32-0.40 | <=0.25 | <=0.20 | / | 0.020-0.050 | / |

Iraeta3 | B3 | 0.61-0.65 | 1.73-1.80 | 0.73-0.80 | <=0.020 | <=0.015 | 0.80-0.88 | <=0.25 | <=0.20 | / | / | / |

Iraeta4 | B3A | 0.60-0.64 | 1.45-1.55 | 0.68-0.76 | <=0.020 | <=0.015 | 0.75-0.85 | <=0.25 | <=0.20 | 0.05-0.09 | / | / |

Iraeta5 | B4 | 0.66-0.74 | 1.2-1.4 | 0.5-0.7 | <=0.020 | <=0.022 | 0.85-0.10 | / | <=0.4 | / | 0.025-0.045 | 0.05-0.15 |

Iraeta6 | B6 | 0.74-0.85 | 0.15-1.35 | 0.90-1.05 | <=0.020 | <=0.020 | 0.88-0.98 | <=0.25 | <=0.25 | 0.06-0.13 | 0.025-0.045 | / |

Iraeta7 | B6-1 | 0.70-0.76 | 0.15-0.35 | 0.90-1.05 | <=0.020 | <=0.020 | 0.88-0.98 | <=0.25 | <=0.25 | 0.06-0.13 | 0.025-0.045 | / |

Iraeta8 | B6A | 0.82-0.90 | 0.15-0.35 | 0.90-1.05 | <=0.020 | <=0.020 | 0.88-0.98 | <=0.25 | <=0.25 | 0.06-0.13 | 0.025-0.045 | / |

Iraeta9 | BU | 0.95-1.05 | 0.15-0.35 | 0.95-1.05 | <=0.025 | <=0.025 | 0.45-0.55 | <=0.0.6 | <=0.06 | <=0.05 | 0.02-0.04 | / |

Iraeta10 | YS901 | 0.77-0.83 | 0.2-0.35 | 0.8-0.9 | <=0.015 | <=0.015 | 0.8-0.9 | <=0.15 | <=0.15 | 0.03-0.08 | 0.02-0.04 | / |

Iraeta11 | S902 | 0.77-0.83 | 0.2-0.35 | 0.9-1.0 | <=0.015 | <=0.015 | 0.9-1.0 | 0.2-0.35 | 0.2-0.35 | 0.12-0.18 | 0.02-0.04 | / |

COMPANY

We are one of the largest hot-rolled wear-resistant steel ball supplier in China, an annual output of

200000 tons of steel ball, products cover dia 25-150 mm . We have four hot rolled steel ball production

line from computer control , the industry's leading automation , less manual intervention, different

batch product stability is high. We are the one of the China few supplier can use the hot rolling

process directly above dia80mm ball , is also one of the few capable of steel raw materials research

and development and customization of suppliers. Raw materials research and development and the heattreatment process of the entire project development, full participation by the shenyang metal

research institute as the Chinese academy of sciences.

1)High quality

High quality comes from every working procedure for the control . Grinding ball have no great

differences in appearance, but in the actual effect of grinding efficiency is different, this is because

the raw material, heat treatment process, equipment automation level and other factors can lead to

the steel ball steel ball lapping efficiency differences, and ultimately affect the user cost of grinding .

Every working procedure we always follow the details of the accused, by providing more wear-

resisting of grinding ball to help customers to reduce the cost of grinding.

1 > Raw material contrast

Ordinary company : directly using the scrap or various steel grades production, traditional little

involvement in the high rate of grinding materials research and development.

Iraeta : have a deep cooperation with The Chinese academy of sciences and steel plant , according

to different industry standard have in-depth research and development, developed raw material

with higher grinding performance.

2 > Heat treatment of contrast

Ordinary company : Usually use pure water cooling quenching with insulation barrels of tempering ,

the heat treatment method is easy to cause uneven hardness, the lack of resilience, steel ball high

broken rate in practical use.

Iraeta : Closed cooling tower for effective control of quenching temperature within the scope of the

standard, the composite heat treatment technology can improve the internal organization of steel ball,

the ball while guarantee the hardness have sufficient toughness are less likely to break.

3 > Production craft contrast

Ordinary company : degree of automation is less than manual intervention, there is no guarantee

that the stability of each batch steel ball.

Iraeta : Fully automated production lines, greatly reduced the manual intervention, to ensure the

stability of different batch grinding steel ball quality.

4 > Quality control of contrast

Ordinary company : Have less testing instrument , and the lack of objective testing standards.

Iraeta : Through ISO17025 laboratory accreditation service international standard certification,

the quality control system though audit for many times, passed nearly 30 different international

industry certificatio.

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Niuyugang

- Address

- Shandong

- Product Category

- Cast & Forged,Other Minerals & Metallurgy Products

- Year Established

- 1975

- No. of Total Employees

- 1001-2000

- Company introduction

-

<p>

We are one of the largest hot-rolled wear-resistant steel ball supplier in China, an annual output of

200000 tons of steel ball, products cover dia 25-150 mm . We have four hot rolled steel ball production

line from computer control , the industry's leading automation , less manual intervention, different

batch product stability is high. We are the one of the China few supplier can use the hot rolling

process directly above dia80mm ball , is also one of the few capable of steel raw materials research

and development and customization of suppliers. Raw materials research and development and the heattreatment process of the entire project development, full participation by the shenyang metal

research institute as the Chinese academy of sciences.

- Main Markets

-

Canada

Canada

U.S.A

U.S.A

- Main Product

Related Products

Heavy duty telecom manhole covers

Plastic injection Mold for Automotive Lamp / Parts

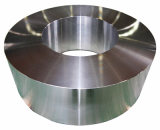

Forged Ring

Sand Sludge Pump Parts

Water Hammer Cushion

China

China