Manufacturer-High Temperature Ceramic Roller

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- furnace rollers, furnace alumina ceramic tube, high temperature ceramic roller, manufacturer high temperature

- Category

- Vacuum Equipment & Parts

Lonci Group Co.,Ltd

- Verified Certificate

-

9

| Product name | Manufacturer-High Temperature Ceramic Roller | Certification | - |

|---|---|---|---|

| Category | Vacuum Equipment & Parts | Ingredients | - |

| Keyword | furnace rollers , furnace alumina ceramic tube , high temperature ceramic roller , manufacturer high temperature | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Product Description

How to use the roller affect not only the service life of the roller but also smooth work of the kiln.Generally,we select the type of roller depending on the maximum firing temperature and load of the roller.Meanwhile,the rotate speed,span of roller and atmosphere in the kiln are also important factors for us to consider,as well as the factors of the gas,molten materials and thermal shock.Considering the factors mentioned above,our suggestions are the following:

Before using the roller,apply protective coating on the surface evenly

Place the roller beside or on the kiln for drying.Only after the roller has been dried can it be put into kiln.

Inserting coated roller to kiln should be completed in a short time,in order to avoid the roller to be heated too long in nonrotating state.

Inserting ceramic fibre t both poles at depth 50-60mm.

Keep the temperature in the kiln at a stable level.Change the new roller whenever any roller broken.

When the kiln is warmed up to 300-400 centigrade,Please insert the rollers and increase temperature steadily.

Whenever glaze droplets or alike deposits appear,the roller should be pulled out for cleaning and then applied with new protective coating.

While the roller is pulled out from high temperature kiln,its bending should be avoided.Place it to a stand matted with thermal insulting material,rotate it continuously until it cools down to below 600 centigrade,or cover it with thermal insulting blanket.

Contact between hot roller and cold metal must be avoided.

Don't use hard tool to knock at roller while cleaning.

Keep the exhausting fan on and roller rotating after shutting down of kiln,turn off the other fans and prevent cold air coming after 24 hours,increase the fan speed and take out the roller when the temperature in the kiln is 500 centigrade or below.

For the kiln using coal gas,be sure to turn down exhausting fans in tme after turing off coal gas and combustion air.

The operation of the exchange heat fans depends on the pressure in the kiln in order to prevent leakage of the cold air and cool the kiln stably.

Prevent the cold air coming into the kiln when it is cooling,special for the kiln used the heavy oil.Adjust the fan speed to balance the pressure in the kiln in a stable level,and slow air current to cool the kiln in a stably.

Avoiding using the roller in the alkali atmosphere and the corrosion of alkali materials in order to prolong the service time of roller.

Product Feature

Excellent insulation

high pressure resistance

high temperature resistance

temperature stability

corrosion resistance

chemical resistance

wear resistance

etc.properties.

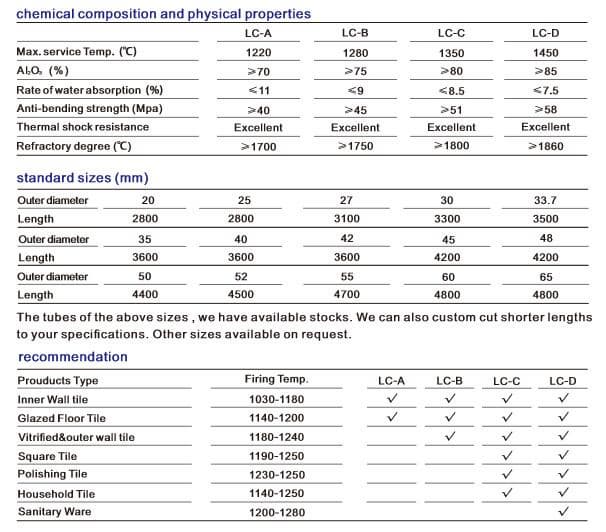

Product Specification/Models

Regular dimension:

OD-length/mm:20-2800/25-2800/27-3100/30-3300/33.7-3500/35-3600/40-3600/42-3600/45-4200/48-4200/50-4400/52-4500/55-4700/60-4800/65-4800

The tubes of the above sizes,we have available stocks.We can also custom cut shorter lengths to your specifications.Other sizes available on request.

Application

Mainly used in electronic enterprises and furnace manufacturing enterprises.

Other Information

Lonci has certificated by ISO 9001 and is able to customize Alumina products to meet your special requirements by high quality raw materials,advanced process technology and production equipment,monitoring and testing methods etc,also,according to your working conditions and operational performance.Until now,we own 10 kilns at Hebei factory and 3 kilns at Jiangsu factory,including top-hat kiln,dome kiln and shuttle kiln.Meanwhile,We can adjust the pressure of Dry press forming machine from 60 tons to 400 tons,we also have purchased High temperature muffle furnace,Bending compression tester,Short-term voltage tester,Laser particle size tester and some other advanced property test machines,by all of which Lonci will ensure every piece of tube has perfect quality.And more,Lonci engages in original designs and have possessed many patents.

In addition, timely delivery, stocks and product information are available.

Should you have any questions, pls do not hesitate to contact me. FREE SAMPLES will be sent for your evaluation!

Note:If we have available stocks for your sizes,free samples can be sent to you but you bear the freight. If your sample is custom-made,you should pay for both the sample fee and freight.

Thanks and best regards!

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Candy Wang

- Address

- NO.66 ShaHe RD,ShangHai,China

- Product Category

- Ceramics,Electroceramics,Refractory,Temperature Instruments

- Year Established

- 2012

- No. of Total Employees

- 101-500

- Company introduction

-

LONCI GROUP is the leading fine ceramic manufacturer which was established in 1988.LONCI has owned 2 factories,and marketing centre,Specializing in developing fince ceramic science & technology,production and trading.The main products are:high quality alumina ceramic tube,alumina ceramic rod,ceramic roller,alumina lining brick,alumina crucible,special industry ceramic.LONCI manufactures over 150,000 pieces quality ceramic tubes,rod and rollers,and over 9,000 tons of alumina lining bricks and other technical ceramics,which help us have a significant share in the world market.

While focusing on technical ceramic production,LONCI pays much attention to technology innovation and research.and has been making a lo of breakthroughs in recent years.Up until now,LONCI is holding many self-developed intellectual property rights.Facing today's new international competition,LONCI has been establishing and implementing Globalization,Famous Brand Strategy and Multi-fields.Until now,our products have been sold to America,Germany,Japan,Italy,Spain,Korea,Egypt,Indonesia,Turkey,Russia,Taiwan Province etc.Our products are providing service for ceramic industry,petrol chemical industry,casting industry,steel industry,mining industry,power industry,petrol chemical industry and chemical industry.LONCI is specilizing in fine ceramic industry,closer to market and customers and providing best solution upon customer's.With high quality products,perfect service and scientific management,the popularity,reputation and social recognition of LONCI is improved greatly.

- Main Markets

-

China

China

Hong Kong(China)

Hong Kong(China)

Japan

Japan

South Korea

South Korea

Taiwan

Taiwan

U. Kingdom

U. Kingdom

U.S.A

U.S.A

- Main Product

Related Products

SHIP SPARE PARTS / ENGINE PARTS / PUMP PARTS / ELECTRIC PART

VMECA Vacuum Needle Gripper

VACUUM PUMP

Total Sputtering (Coating) System

Carbon Graphite Parts For Vacuum Furnace