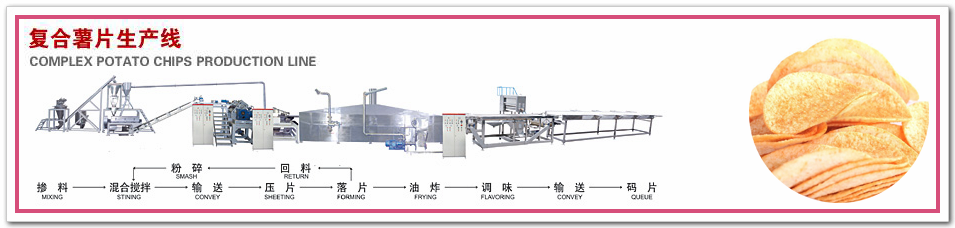

Complex Potato Chips Production Line

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- HuaXing or OEM

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Beverage & Wine Processing Machinery

Shantou Huaxing Machinery Factory Co., Ltd

- Verified Certificate

-

9

| Product name | Complex Potato Chips Production Line | Certification | - |

|---|---|---|---|

| Category | Beverage & Wine Processing Machinery | Ingredients | - |

| Keyword | snack food machinery , chips fryer , chips snacks making , chips making machine | Unit Size | - |

| Brand name | HuaXing or OEM | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

HX Complex Potato Chips Production Line processes potato

powder as original material into crisp fried chips in same shape, very suitable

to paper-canister package term or other regular plastic package. For years, we

assemble details from both domestic and foreign markets and combine the

technology from the same areas, well-considered and finally designed and

finished this production Line. With this production line, chip manufacturers

could produce potato chips in most of the areas without fresh potato, in this

way they could lower the cost on importing fresh potato, and conveniently use

potato powder to finish the whole processing of potato chips.

Main Technical Parameters:

1.

Capacity: 200-250kg/h

2.

Production Area: 40000mm*8000mm*43mm

3.

General Power: 86Kw

4.

Diesel Consumption (For Heating):

BTL100DSG Double 45-100kg/h.

5.

Gas Consumption (For Heating): BGN60P

Double, Nature Gas 28-101m3/h, Liquid Gas 14-46.6m3/h.

6.

Operation Personnel: 10-13 persons

7.

Oil Content After Frying: 35%

8.

Water Content After Frying: 3%

9.

Seasoning Content: 5%

10. Thickness of a Piece of Chip: 0.6mm thickest

11. Weight of a Piece of Chip: 1.6g

12. Dimension of a Piece of Chip: 58×45

13. Frying Scale: 17 rows.

14. Capacity of Every Minute: 2600 pcs/minute

15. Time of Frying: 18 second(Adjustable)

16. Temperature of Frying: around 180℃, can be 200℃

17. Power of Frying Machine Circulating Pump: 22kW

18. Water Consumption of Production Line: 120kg/h

19. Capacity of Air Compressor: 4.6m3/min

20. The Level Of Eatable Oil: 150mm

21. Quantity of Oil Contained in Frying Machine: 1.2m3

22. The Oil tank is with Thermal Insulation. 2 Parts inside, 1 Ton/Part. The Frying Machine Needs 500kg.

Notice: About the capacity per

hour, it also depends on the material which is used by operators. And, although

our machine lines are designed as easy and simple to be operated by trained

workers as we can, but for obtaining the best quality of the final products, we

faithfully suggest all of our customers read our instruction books very

carefully before formally starting up the production line.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Huang Hankun

- Address

- NO.M1. Rongsheng Science Park. Daxue Road Shantou City, Guangdong Province China

- Product Category

- Beverage & Wine Processing Machinery

- Year Established

- 1991

- No. of Total Employees

- 101-500

- Company introduction

-

Shantou Huaxing Machinery Factory Co., Ltd is a professional manufacturer for snack machinery. We started to produce the snack machines around 28 years ago.

We have sold our machines to over 40 countries already. We have obtained ISO9001:2000 certificate.

The main products as below:

Extrusion system production line of snack pellets

Fresh potato chips production line

Extrusion system line of puff snack

Pillow & stick snack production line

Steam cooking system production line of snack pellet

Bean & peanut processing production line

Complex potato chips production line

Twist production line

Custard cake production line

Bun production line

Series of Fryers, dryers, and seasoning machines

- Main Markets

-

Bahamas

Bahamas

Belize

Belize

China

China

North Korea

North Korea

Pakistan

Pakistan

Philippines

Philippines

Singapore

Singapore

South Korea

South Korea

- Main Product