Quick repair method for rubber conveyor belt scratching

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- ramimtech

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Rubber Belts

Zhengzhou Dipute Chemical Co.,Ltd.

- Verified Certificate

-

12

| Product name | Quick repair method for rubber conveyor belt scratching | Certification | - |

|---|---|---|---|

| Category | Rubber Belts | Ingredients | - |

| Keyword | conveyor belt repair , cold vulcanization repair | Unit Size | - |

| Brand name | ramimtech | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Quick repair method for rubber conveyor belt

scratching

When conveyor belt running under high load

capacity, whose surface will be torn or longitudinal scratching, if we don’t

repair in time, it will be cause big affect to normal production, then affect

the economic benefits of enterprises.

After it appears scratching problem, we have to do quick repair, because we have limit halt time. If we choose traditional hot splicing method, though stable and reliable, but it waste time and affect operation time. So whether we have a method to repair it in short time? The answer is positive.

Ramimtech cold repair method choose high quality, abrasion resistant repair materials, applies the bonding technology that semi-cured layer bonding with cold vulcanizing glue sk313,not only easy construct, but also reliable technology, after repair, we can operate it immediately, which saves halt time and enhance the repair efficiency.

Repair methods for conveyor belt repair

First step: sand damaged parts, mark the damaged area, the marked part should be larger than the damaged part, then use the angle grinder L1202 together with K23 tungsten carbide buffing disc to sand the damaged part until the damaged part present a certain radian and no protrusion.

Second step: clean damaged parts, use brush to clean it, then use cleaning solvent to deeply clean it, wait until it dries.

Third step: brush cold vulcanizing adhesive, brush a coat of cold vulcanizing glue SK313 on damaged parts until it totally dry. Then brush cold vulcanizing glue SK313 the second time, meanwhile, repair strip whose semi-cured layer should brush a coat of cold vulcanizing glue SK313, until both of them have little stickiness and begin to bond them.

Forth step: combine repair strip along the damaged parts, avoid air in, after combine, use hand roller to press the repair parts from inner parts, and discharge air.

Notice:

If conveyor belt repair parts appears pierce

through or pierce pass phenomenon, we should bond the working part and

non-working part with repair strip, and fill the damaged parts with rubber

repair agent SK786, then directly bond the repair strip.

Apply Ramimtech cold vulcanizing repair methods, which suitable for Power Plant, Steel plant, coking plant, cement plant, granary, mine, dock and subway units, the technology is easy operation, no need for big equipment such as vulcanizing machine, which can realize quick repair to damaged parts, after repair, it can reach the work intensity immediately, and start-up and use.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Brant Gao

- Address

- NO.1shangdu Road, New Eastern district Zhengzhou Henan 450000 China

- Product Category

- Epoxy Adhesives,Rubber Sheets

- No. of Total Employees

- 1-50

- Company introduction

-

Founded in 1998,Located in Zhengzhou City of Henan Province,China.Zheng Zhou Dipute Chemical Co.,Ltd,which is a professional manufacture & Supplier to provide a complete range of conveyor services and products to the mining and materials handling industry. All of our products have obtain the ISO9001-2008 certification.The excellent quality is reliable and winning a good reputation from our customers around the world. Our professional team consists of skilled belt workers and tradesman, backed up by technical staff with extensive experience in the minerals, mining and heavy industrial sectors.Our goal is to provide solutions to our customers tougest problems in conveyor belt system.

- Main Product

Related Products

SPINDLE TAPE AND TANGENTIAL BELT

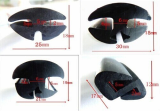

Neoprene Rubber Seal Strip

General Rubber Sheet

window seal strip

door seal strip

China

China