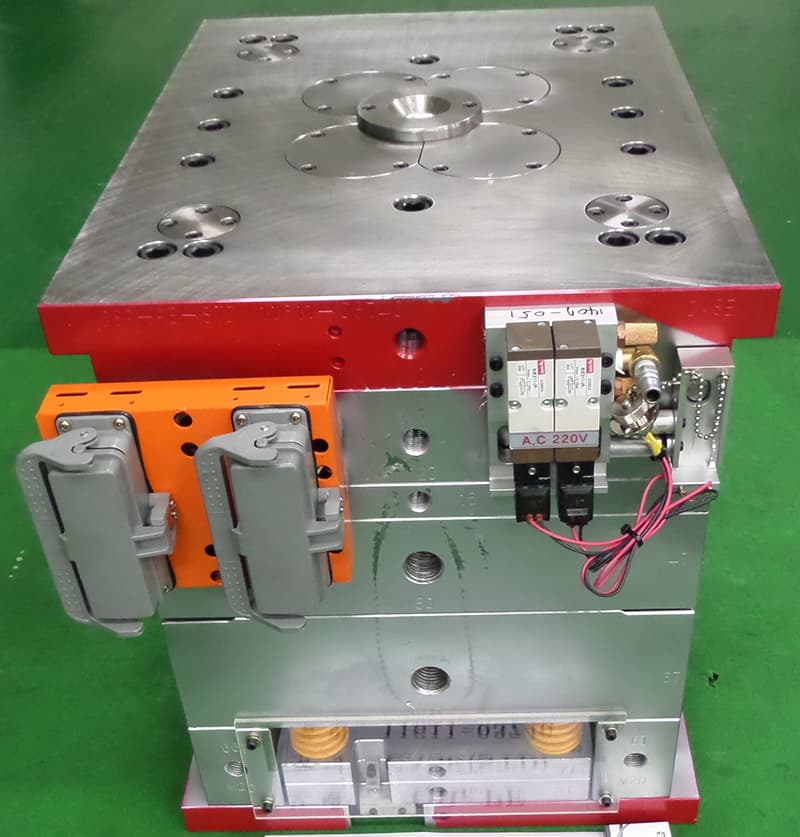

Main production injection molds

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- injection mold, mold, plastic injection mold, tooling

- Category

- Other General Industrial Equipment

Dongwoo Mold Technical Co.

- Verified Certificate

-

9

| Product name | Main production injection molds | Certification | - |

|---|---|---|---|

| Category | Other General Industrial Equipment | Ingredients | - |

| Keyword | injection mold , mold , plastic injection mold , tooling | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

Main production injection molds

│ DESCRIPTION │

We follow prevention-oriented philosophy before starting a new project Special Review Team consists of Engineering department, Manufacturing department, Project Department, Quality Control Department and Purchasing Department adopts mold flow analysis, experience summary of similar projects and precaution potential problems of customers requirements, thereby to ensure the product quality effectively.

We are a custom mold factory. Could you kindly send your design(pdf file drawing),the size,the weight,the material,quantity to me? I will make a competitive price to you at once!

│ MOLD SPECIFICATION │

Accept customer custom all kinds of plastic injection mold Good Quality customer Trade Assurance Customized Injection Plastic mold

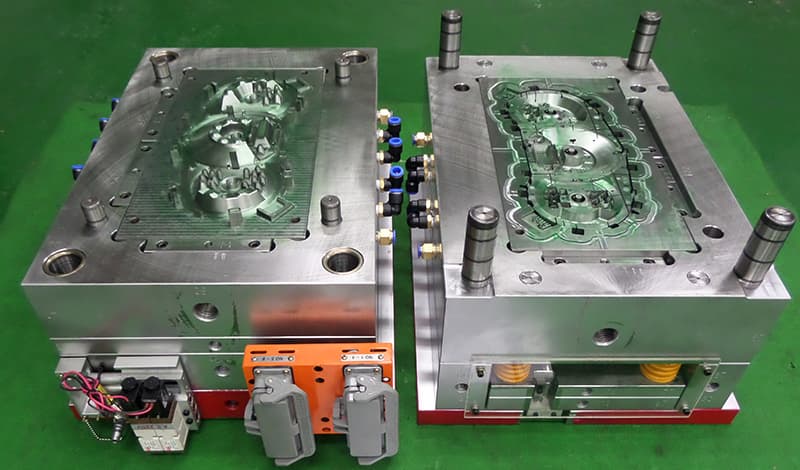

│ MOLD MAKING │

1) Material of steel

cavity and core use imported S136 stainless steel with fine polishing, high hardness to get mold's high precision and good quality.

2) About gate

pin-valve gate ,pneumatic drive the nozzle pin simultaneous high speed open and close action. which can effectively control the injection hole open and close actions on each cavity. reliable seal function, smooth moving, low thermal expansion rate ,long using life and also saves electric energy.

3) About hot runner

hot runner system is designed and made by ourselves, it can achieve ideal and prompt heating effect for preform production ,cavity with lower injection pressure to reduce wear and tear of mold parts.

4) Cooling system

each parts including core ,cavity and valve gate has independently cooling system.

│ OUR ADVANTAGES │

1) R&D (Design according to client's drawing and requirements)

2) Professional mold manufacturer

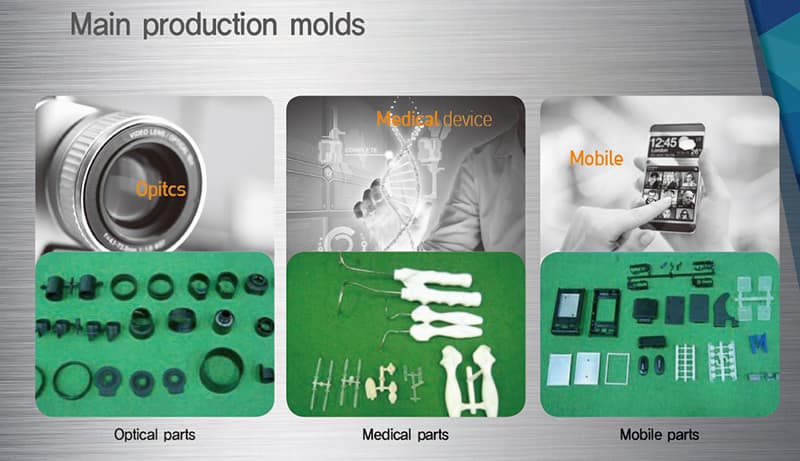

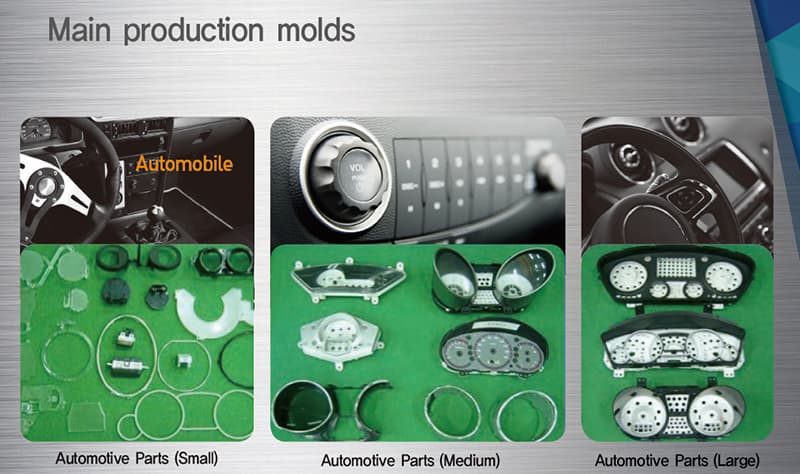

3) Molding parts, such as led lamp parts, car parts, auto accessories, electronic components, medical products, office appliance, etc.

4) Various materials and short lead-time

5) High quality steel and long mold life .

6) We can supply "one-stop" service with molds opening,injection,painting,screen printing,assembly and good after-sales

7) Full set machines for mold making and products injection

8) mold's steel as per customers' requests such as NAK80, S1369(H),2738, 718, 738 and etc.

9) Various used plastics: ABS,PP,PE,POM,PA6(66)+GF,PC,PMMA,HIPS,GPPS and etc.

10) Certifications Authorized: ISO9001, SQ

│ MOLD SPECIFICATIONS │

| mold steel | NAK80, S136, 718H, SKD61 etc |

| Plastic material | PP, PS, PE, PET, TPR, PVC, PA, POM, ABS, PC PPR etc. |

| mold base | LKM, ML, HASCO etc. |

| Normalize parts | D-M-E, HASCO, JIS etc. (customer demand) |

| Software | CAD/CAM/CAE |

| Dimensions of the mold | Info from us |

| No. of cavity | Single/Multi |

| Min mold life | Different steel different production, min mold life 200,000 shots |

| Doff way | Auto by ejectors, Doff plates, Air valves etc |

| Lead time | 2weeks-2 months |

| Process | CNC, High speed carve, E.D.M, Wire cut, Drill, Injection etc. |

| Packing | Plywood case |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- KIM JONG HYUN

- Address

- 1205-13, Hallim-ro, Jinyeong-eup, Gimhae-si, Gyeongsangnam-do, Korea

- Product Category

- Plastic Rolling Machinery

- Year Established

- 1997

- No. of Total Employees

- 1-50

- Company introduction

-

Dongwoo M-Tech is professional manufacturer of mass production and technology development at all area, such as Automotive and Electrical, Electronic, Optic, Mobile telecommunication, Shipbuilding, Aviation, etc. company which is recognized competitiveness from customers through Challenging thinking and combining the advanced mold technology.

- Main Markets

-

South Korea

South Korea

- Main Product