kupper ceramsite/ceramic foundry sand/spherical foundry sand

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Metal & Metallurgy Machinery

Kupper Corporation

- Verified Certificate

-

9

| Product name | kupper ceramsite/ceramic foundry sand/spherical foundry sand | Certification | - |

|---|---|---|---|

| Category | Metal & Metallurgy Machinery | Ingredients | - |

| Keyword | ceramic foundry sand , ceramsite sand , spherical foundry sand , green foundry sand | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

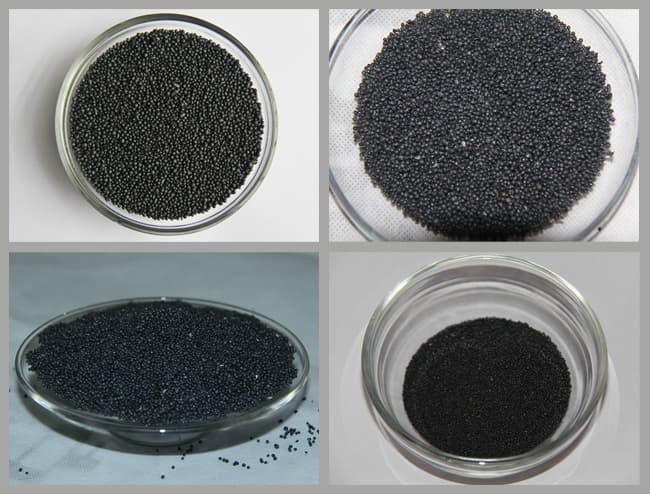

Kupper Ceramsite - An Artificial Foundry Sand, Substitute For Chromite Sand, Zircon Sand, Cerabeads and Silica Sand

"CERAMSITE" was then also called "CERASITE", "CERAXITE", "CERASAND", "CERAMIC FOUNDRY SAND" and "SUNPEARL" by our customers in other countries. It is a kind of brand new artificial foundry sand, originally coming from China only. With much better comprehensive property and price comparison, it is regarded as the right substitute for chromite sand, cerabeads, zircon sand and silica sand. By over 10 years application in world casting industry, it is now well known as a revolution for new foundry sand. By choosing our ceramsite as a cost effective foundry sand, you will surely save production costs and improve your casting quality.

The calcined bauxite is used as raw material to be remelted and blown into solid ball shape by high temperature spray. It is in high smooth surface, good air permeability and excellent dispersibility. It can obviously reduce the binder addition for resin coated sand (RCS) and self-hardening sand. It can greatly save the sand consumption because it can be reclaimed for many times and always in low breakage rate during crushing. The mature application proves it is an ideal foundry sand for the casting of carbon steel and alloy steel (heat resistant steel, abrasion resistant steel, atmospheric corrosion steel, and other acid and basic steel category). It is widely used as core sand and facing sand.

Please find its chemical compositions and physical properties as follows:

Al2O3: 75 ~ 80%

SiO2: 8 ~ 25%

Fe2O3: 5%Max (normal grade: Fe2O3 <= 5%, special grade: Fe2O3 <= 3%)

TiO2: 5%max

Refractoriness: 1, 790 degrees centigrade

Angle coefficient: 1.1max

Thermal expansion (at 100 deg C): 0.15

Thermal conductivity: 0.196 w/m@k

Specific heat: 873 J/kg.

Bulk density: 1.95 ~ 2.05 g/cm3

The particle sizes available are: AFS20, 25, 30, 35, 40, 50, 60, 75, 80, 100, 125, 140, or 0.2~0.6mm, 0.3~0.7mm, 0.4~0.9mm, 0.9-1.25 mm, 1-2mm, 200mesh, 325meesh, etc...

Let us summarize its all features or advantages as follows:

1. Round solid ball shape, saving binder addition;

2. High refractoriness and service temperature;

3. Good air permeability and excellent dispersibility;

4. Lower thermal expansion rate and thermal conductivity;

5. Lower bulk density, lower true specific gravity and lower specific surface area;

6. Standard particle sizes;

7. Easily reclaimed and lower breakage rate during dry crushing;

8. Single application, no need mix with other foundry sands;

9. To reduce pollution and protect environment.

Our product is graded by different contents of Al2O3, Fe2O3, K2O and Na2O. Accordingly pricing differ too. Should our product be of interest to you, please contact us for further discussion about detailed specifications and quotations. We are always ready to meet you on all aspects. Thanks for your attention and cooperation. aluminachina.com

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Alex

- Product Category

- Refractory

- Company introduction

-

Kupper ,located in Shandong China, focused on global markets for grinding media in chemical and beneficiation fields, is one leading manufacturer and top exporter of alumina ball, ceramic foundry sand .aluminachina.com sales@aluminachina.com

- Main Product

China

China