Guangxi Menghua sell high purity manganese oxide powder

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- feed additive, micronutrients fertilizer

- Category

- Oxide

Guangxi Menghua Technology Investment Co., Ltd

- Verified Certificate

-

8

| Product name | Guangxi Menghua sell high purity manganese oxide powder | Certification | - |

|---|---|---|---|

| Category | Oxide | Ingredients | - |

| Keyword | feed additive , micronutrients fertilizer | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

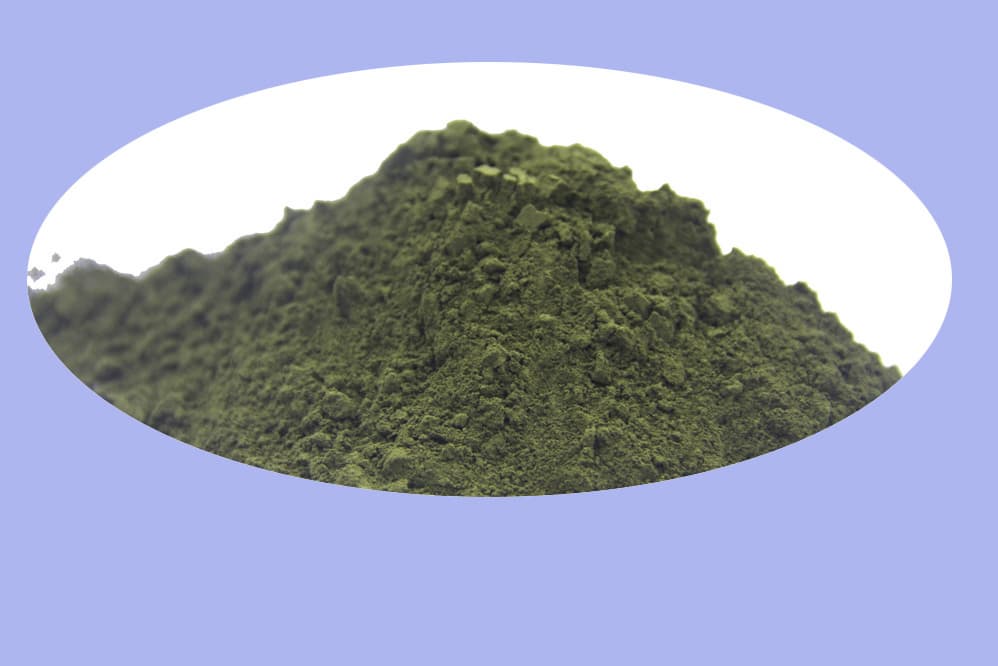

MNO(I), MNO(II)

MENGHUA

Feed additives, Catalyzer, ect.

Green / olive green powder

99%

electronic , Agricultural

China

EINECS :215-695-8

:MNO

CAS NO.: 1344-43-0

manganesegreen, manganesemonooxide, manganeseprotoxide, manganosite

Certificate: CCIC/SGS/ BV Inspectorate

Sample: for free by DHL

Metric Ton

10

L/C T/T

Qinzhou port/Huangpu port of China

2500 Metric Ton per Month

5-15 working days after the reception of L/C or T/T

plastic lined woven bag, 25KG or 50KG per bag

Application

It is used as high-quality feed addictives; catalyzer, dryer, micronutrients fertilizer. It is also widely used in the production of medicine, metallurgy, weld, dry cell and the reducing dyeing of textile, the color of glass, the bleach of grease.

Packaging &Shipping &Certificate

l Packing : plastic lined woven bag, 25KG or 50KG per bag

l Shipping: By container

l Certificate: issued by CCIC or SGS or other third party mutually agreed

Notices for operation , storage & transportation, Toxicity

l It is suggested that training worker shall operate by wearing professional equipment.

l It shall be Store in a cool, dry, well ventilated place and stayed away from fire & heat, stored separately from oxidizing agent , acid and food.

l MnO dust can cause manganoconiosis

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- wei qingmeng

- Address

- No.90 Jianshe Road, Qinzhou, Guangxi , China

- Product Category

- Oxide

- Year Established

- 2008

- No. of Total Employees

- 101-500

- Company introduction

-

Our company is located in Qinzhou City of Guangxi Province, which is known as the ASEAN international trade center. QINZHOU RARE EARTH REFINING FACTORY was founded as the predecessor in 1993, and was renamed to be SOUTHEAST MENGHUA MINING CO., LTD. under sales expansion in 2003. In 2008, she was restructured as GUANGXI MENGHUA TECHNOLOGY INVESTMENT CO., LTD. with registered capital of CNY Forty-one million yuan, so as to satisfy the requirement of enterprise’s strategic development.

We have devoted ourselves to the research, development and application of the MANGANESE for more than 20 years, and now becoming a global integrated server towards Manganese related metallurgical & chemical products for raw materials, equipments, technologies and professional solutions. There are 250 staffs in our company, including 30 middle and senior management personals and 10 technical professionals.

Manganese raw materials: Working closely with the major miners such as Samancor, VALE, NOBLE, OM, COMILOG, PILBARA, UMK, GLENCORE etc, we stably supply manganese ore, which originating in Australia, Brazil, South Africa etc. We have been cooperating with a Miner in Kelantan Malaysia for the exploitation of Manganese ore with MN32%-35%. The capacity of the Mine is 5,000,000.00 MTS and the annual output is 200,000.00 MTS. Kelantan Mn ore is selling well due to the good quality and competitive price. Our annual sales are 300,000.00MTS totally.

Metallurgical Products: We have invested and joined with Indonesian plant and Vietnam plant by utilizing rich raw materials and developed technologies. The Indonesian plant produces 80000 MTS SIMN6517 annually, while the Vietnam plant produces 150000 MTS SIMN6517, 40000MTS LOW CARBON FERRO MN & MEDIUM CARBON FERRO MN & HIGH CARBON FERRO MN annually. Our company can supply the above products with low price and high quality by taking comprehensive advantages of the industrial chain.

Chemical Products: We offer raw materials and technologies for fodder and chemical & industrial chain. As our core product, the high purity MnO powder is of 30000MTS annual outputs. There are also other products, developed in our company, such as high purity MnO2 powder with 10000 MTS annual outputs, Electronic-grade high purity Manganese sulfates with 3000MTS annual outputs. We also trade O-Methylhydroquinone, feed-grade Zinc sulfate, Ferrous sulfate, Copper sulfate etc.

Technologies: The technology for the production of Manganese residual , Pig iron and the by-production of Silver ingot by using low grade Manganese ore.

The technology of electricity generation by using the hot waste heat of the blast furnace’s off-gas.

The Technology for the production of High purity Manganese sulfate and by-production of Zinc ,indium and silver by wet processing extraction from deep-sea manganese nucleus polymetallic ore. It has been patented. The patent and technical equipment for the production of MnO by reducing MnO2.

The simplified, movable-type and environmental friendly production equipment for sintering.

The cogeneration technology by using the off-gas from submerged arc furnace.In 2008, GUANGXI HUASHENG THERMAL ENERGY CO., LTD. was founded by using the hot waste heat of the submerged arc furnace off-gas for electricity generation with annual outputs of 25000MTS, which is a milestone on our way for Mn development & application.

Upholding the principles of morality development and win-win relationship, and believing customers first, honest operation and people-oriented, we will offer you superior products and services. We are looking forward to your enquiries sincerely.

- Main Product

Related Products

Ceramic Valve Seats

TITANIUM DIOXIDE RUTILE GRADE KR-1000

ath, aluminium hydroxide, aluminum hydroxide, high whiteness

TiO2 R-6618

AF Coating Material

China

China