Briquetting Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- briquetting, briquetting machine, roll, roller

Jeil Machinery

- Recent Visit

- Jan 08, 2025

- Country / Year Established

-

South Korea

/

2001

South Korea

/

2001

- Business type

- Manufacturer

- Verified Certificate

-

10

| Product name | Briquetting Machine | Certification | - |

|---|---|---|---|

| Category |

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment |

Ingredients | - |

| Keyword | briquetting , briquetting machine , roll , roller | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

Briquetting Machine

│ Introduction │

“Briquetting” is able to change a valueless fine dust and particle into a mass which can be a useful material in various industrial fields.

During briquetting, fine particles are compacted between two counter rotating rolls and become to briquettes.

Recently, in fields of material recycling, many companies introduce the briquetting machine in order to obtain the competitiveness of raw materials. This process can induce a reduction of production cost and provide high quality, inexpensive products to industrial fields.

│ Type of Briquetting Machine │

| Hot Briquetting Machine | |

|

* Application of materials : • DRI(Direct Reduction Iron) • Manganese Ore • Steel Waste Materials, etc. * Capacity : 50 ton/hr * Roll Size & Power : Φ1500ⅹ402W, 680HP * Applicable Temperature : ~ 800 ℃ |

|

| Cold Briquetting Machine | |

Cold Briquetting Machine installed in POSCO |

* Application of materials : • Coal • Cu/Zn Sludge and Mineral Dust • Mill Scale and Steelwork/Industrial Dust • Dried Sludge • Pharmacy • Confectionary * Capacity : 1 ~ 50 ton/hr * Roll Size & Power : Φ800ⅹ504W, 75HP * Applicable Temperature : ~ 200 ℃ * Customer : POSCO, DSI, LS Nikko, Korea Zinc, etc. |

| Lab scale Briquetting Machine | |

Briquetting Machine installed in RIST, Korea |

* Capacity : 250kg/hr * Roll Size & Power : Φ400ⅹ44W, 7.5HP * Material of application : Mineral * Customer : RIST, Korea KIER, Korea IAE, Korea KCC Research Lab., Korea |

│ Assembling Process of Briquetting Machine │

Assembling Process of Hot Briquetting Machine with Segment Roll Type Roll

Assembling Process of Cold Briquetting Machine

│ Specifications for Design │

• Production Capacity : 50 kg/hr ~ 70 ton/hr

• Design Temperature : -40℃ ~ 800℃

• Roll Type : Ring Type and Segment Type

• Compacting Process : With Binder or Without Binder

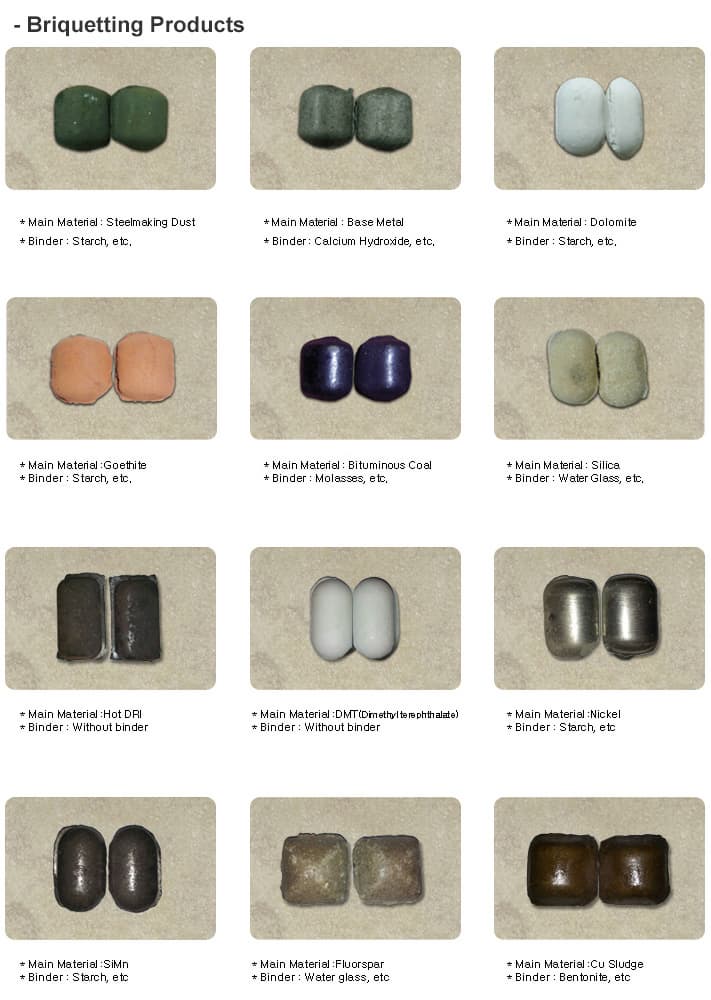

│ Products of Application │

• Dried sewage sludge

• Filter dusts

• Iron oxide

• Magnesite

• Sponge iron

• Cokes powder

• Anthracite powder

• Industrial waste

• Pharmacy

• Confectionery

• Mill scale

• Mineral dust

• Drying sluge

• Ashes

• Coal

• Steelwork dusts, etc.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- 박상규

- Address

- Ocheon-Eup, Cheolgangsandan-ro 130beon-gil, 207-2, Nam-gu, Pohang-si, Gyeongsangbuk-do, Korea

- Product Category

- Metal & Metallurgy Machinery,Other Machinery & Industry Equipment

- Year Established

- 2001

- No. of Total Employees

- 1-50

- Company introduction

-

JEIL has focused on the development of excellent briquetting machine which is a essential apparatus in fields of steel making process, non-ferrous metal refining and material recycling process for many years.

As a result of our efforts, JEIL supplied hot & cold briquetting machines to POSCO, etc. and Lab & Pilot scale machine to many research institutes.

Recently, We come to make contracts to supply cold briquetting machine with KoreaZinc and LS-NIKKO of non-ferrous metal refining companies. Furthermore, in the first half of this year, JEIL supplied a full system which contain a feeder running at 800℃, hot briquetting machine and crusher, to SHAGANG Steel Making Company. We also supplied full Briquetting Plnat System to QATAR Steel Company in 2014-2015 .

- Main Markets

-

China

China

India

India

Iran

Iran

Uzbekistan

Uzbekistan

- Main Product

Related Products

UIM2901-5A MACH3 break out board for CNC

Date Pin (Date Core)

12V Kiosk and Receipt thermal printer HMK054

Marine Loading Arm

Airless Pump (Ratio 63:1 Airless Pump)