6300mm CNC Radial-Axial Forged Ring Rolling Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- LS

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- ring rolling machine, ring rolling mill, horizontal ring rolling machine, horizontal ring rolling mill

- Category

- Metal & Metallurgy Machinery

LS Heavy Industry Engineering Co., Ltd.

- Verified Certificate

-

10

| Product name | 6300mm CNC Radial-Axial Forged Ring Rolling Machine | Certification | - |

|---|---|---|---|

| Category | Metal & Metallurgy Machinery | Ingredients | - |

| Keyword | ring rolling machine , ring rolling mill , horizontal ring rolling machine , horizontal ring rolling mill | Unit Size | - |

| Brand name | LS | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

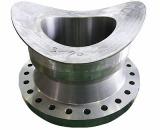

LS ring rolling machines are used where the diameter of the blanks needs to be increased in order to produce rings. For this the blanks are heated to forging temperature and their wall thickness reduced during radial ring rolling by a main roll and a mandrel roll. For radial-axial ring rolling, two axial rolls reduce the height of the blanks simultaneously.

Our ring rolling machines produce rings with rectangular cross-sections and a variety of inside and outside profiles. Many important flange companies in China nationwide where our ring rolling machines are competently performing

Max. outside diameter of rolled ring for individual model:

630mm/1000mm/1250mm/1600mm/2000mm/3500mm/5000mm/6300mm/8000mm/900mm0/10000mm/12000mm

Applications

Carbon steels

Low and high-alloy steels

Austenitic steels

Super alloys such as Inconel, Hastelloy, Waspaloy, Incoloy, Nimonic

NF metals such as titanium, aluminium and copper alloys

6300mm CNC radial-axial ring rolling machine

|

Model |

D53K-6300 |

|

Radial rolling force, kN |

4000 |

|

Axial rolling force, kN |

3150 |

|

Cone rolls angle, ° |

30 |

|

Linear velocity, m/s |

1.3 |

|

Motor for radial rolling, kW |

2x500 |

|

Motor for axial, rolling, kW |

2x500 |

|

Rolled ring

OD, mm |

900-6300 |

|

Space between cone rolls, mm |

100-1000 |

|

Max. blank height, mm |

850 |

|

Max. thickness of blank, mm |

700 |

|

Max. thickness of rolled ring, mm |

420 |

|

Machine length, mm |

25000 |

|

Machine width, mm |

5800 |

|

Machine height (above floor), mm |

7200 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Sheng Hongwei

- Address

- New Orient Plaza, Zhangjiagang City, Jiangsu Province

- Product Category

- Metal Forging Machinery

- Year Established

- 1953

- No. of Total Employees

- 101-500

- Company introduction

-

Our Business

LS Heavy Industry Engineering is a China company experienced in the design and make of open-die forging equipment and engineering. The know-how of our company built-up in long development offers product much more performance and reliability than others. Now we are one of the leading companies in the industry field in the world.

Our Work

We have improved and dedicated expertise to develop products with the goal to meeting customers’ highest expectation. No compromise on performance availability. Both economic and sustainable production for customers is always concerned.

The Quality of Our Products

We are extremely strict in the design and manufacture such as frame rigidity, column guides, eccentric load distributions, forging accuracy and speed, working safety, and electronic controls. They are very important to the whole equipment and engineering project. The manufacture and assembly combines master craftsmen and modern plant facilities. As the forerunner in China, we drafted and issued Chinese National Standard for Two Columns Open-Die Forging Press Models and Parameter, and publication “Forging Handbook”

Our Customers

Our installations can be found in nearly all important railway train plants, petrochemical equipment plants, power equipment plants, aeronautical equipment plants, and steel mills in China. They are: CSR Corporation Limited ( www.csrgc.com.cn), Taiyuan Mining Machinery Group Co., Ltd (www.sxkuangji.com), Shenyang Locomotive Factory Co., Ltd (http://en.sychinacnr.com), Nanjing Steel Group ( www.njsteel.com.cn), China Aerospace Science & Industry Corp. ( www.casic.com.cn), China CNR Corporation Limited ( http://en.chinacnr.com), CNPC Baoji Oilfield Machinery Co., Ltd ( www.bomco.cn), AVIC Shangda (www.shangda.avic.com), Inner Mongolia North Heavy Industries Group Corp. Ltd. (www.bfzg.com)

Our History

The predecessor of the company – LS Factory was founded in 1953, we initially produced castings, forgings and petrochemical equipments in 1965, and started the design and development of two columns open-die forging presses in 1982. Since LS Group’s foundation, we have become nationally recognized for our diverse range of specialty forging equipment and machinery.

Milestones

1953 LS Factory was founded in Lanzhou City in Gansu Province by the Industry Department of China. It is the predecessor of LS Group

1982 LS Heavy Machinery was founded in Lanzhou City in Gansu Province by LS Group

1987 China's first 8MN two-column open-die forging press was manufactured by LS Heavy Machinery

1995 China's first 16MN two-column open-die forging press was manufactured by LS Heavy Machinery

2004 China's first 20MN two-column open-die forging press was manufactured by LS Heavy Machinery

2008 China's first 45MN two-column open-die forging press was manufactured by LS Heavy Machinery

2013 China's first 1.6MN radial forging machine was manufactured by LS Heavy Machinery

2014 LS Group relocated to new facilities in the Lanzhou New Area, the state-of-the-art plant covers a total area of 25,115,000 square feet

2014 LS Heavy Industry Engineering was founded in Zhangjiagang City in Jiangsu Province by LS Heavy Machinery for new technology development, international engineering, sales and service

- Main Markets

-

U.S.A

U.S.A

- Factory Information

-

LS Heavy Industry Engineering Co., Ltd.

- Main Product

Related Products

FORGED NOZZLE

Ceramic Foam Filter CFF-S

Automatic Rebar Bending Line

Corundum-Mullite Crucibles For Melting Steel

Waste, Cement, Lime Rotary Kiln with capacity 50-800TPH

China

China