high quality bmc smc material(bulk/sheet molding compound)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- smc bmc

- Payment Terms

- D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Plastic Raw Materials

Wenzhou Jintong Complete Appliances Co., Ltd.

- Verified Certificate

-

10

| Product name | high quality bmc smc material(bulk/sheet molding compound) | Certification | - |

|---|---|---|---|

| Category | Other Plastic Raw Materials | Ingredients | - |

| Keyword | thermosetting plastic , bmc smc material , smc bmc compression injection , fire glass | Unit Size | 10.0 * 10.0 * 10.0 mm |

| Brand name | smc bmc | Unit Weigh | 100 g |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Bulk Molding Compound (BMC) is a thermoset plastic resin blend of various inert fillers, fiber reinforcement, catalysts, stabilizers, and pigments that form a viscous, 'puttylike' injection molding compound. Bulk Molding Compound (BMC) is highly filled and reinforced with short fibers. Glass reinforcement represents between 10% and 30%, with glass length typically between 1/32-inch and 1/2-inch (12.5mm). Depending on the end-use application, bulk molding compounds are formulated to achieve close dimensional control, flame and track resistance, electrical insulation, corrosion and stain resistance, superior mechanical properties, low shrink, and color stability. Its excellent flow characteristics, dielectric properties, and flame resistance make this thermoset material well-suited to a wide variety of applications requiring precision in detail and dimensions as well as high performance. The material is available in a broad selection of colors, and can tolerate powder-coat or water-based paint.

Features of BMC(Bulk Molding Compounds):

High production efficiency, easy to implement specialized and automated production;

With high accuracy dimensions, good repeatability.

Smooth surface, no secondary modification.

Can produce complicated structure products by one time.

Relatively inexpensive because of mass production.

Excellent electrical properties, high mechanical strength, realiable flame resistance

arc resistance, and reliable dimensional stability.It can be moulded at low pressure in short period. Widely used in the electircical field, civik construction, railway industry, and automobile field.

Please feel free to contact us if you need more information about us.

We will do our utmost to meet your requirments .Thank you !

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Mr.Shi

- Address

- Wancang Industrial Park, Beibaixiang, Yueqing, Zhejiang Province, P.R.C.

- Year Established

- 2001

- No. of Total Employees

- 101-500

- Company introduction

-

Wenzhou Jintong Complete Appliances Co., Ltd. focused on the thermoplastic industry packages, to provide users with unsaturated polyester resin complete solutions.Businesses include mold manufactureing, BMC/SMC products mission production of injection mould, SMC/BMC products processing and injection, bakelite products and processing, wood processing, and thermoset products processing.

- Main Markets

-

U.S.A

U.S.A

- Main Product

Related Products

_2.jpg)

Biodegradable dishes(PLA)

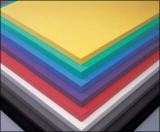

PE EVA Foam

SBS (Styrene Butadiene Styrene)

LDPE Film Scraps

PVC RESIN PLASTIC ADDITIVES

China

China