Cattle Feed Manufacturing Plant

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- India

- Brand name

- SHREEJI

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- cattle feed manufacturing plant

Shreeji expeller Induatries

- Verified Certificate

-

10

| Product name | Cattle Feed Manufacturing Plant | Certification | - |

|---|---|---|---|

| Category | Fruit & Vegetable Processing Machines | Ingredients | - |

| Keyword | cattle feed manufacturing plant | Unit Size | - |

| Brand name | SHREEJI | Unit Weigh | - |

| origin | India | Stock | - |

| Supply type | - | HS code | - |

Product Information

Specifications

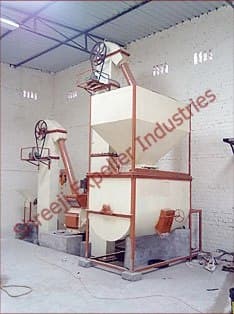

Cattle Feed Manufacturing Plant

Crushing of Material,Mixing

Making Pellets for the Feed

and Cooling the Pellets

CATTLE FEED MANUFACTURING PLANT:

Shreeji Offers Complete Cattle Feed Manufacturing from Disintegrating to Mixing up to Palletizing for the easy eats for the Cattles. These plants in very much demand to mix the various ingredients and make the proper feed for the cattle feed industry

Hammer Mill

Hammer Mills are mainly used to disintegrate the

product to a desired size ensuring proper pelletizing or for the mixing to made the Cattle feed.

Mixure Machine

Mixture Machine is Used to Mix the different ingredients of the cattle feeds in a batch.

It has a strong body with built in reduction Gear box .

Easy to Opearte and Maintain

Feeding System is manual and ensures even mixing of different ingredients of Cattle feed Plant

Hopper for Mixture

Hopper ensures the Easy travelling of material to mixture and also the storage for materials for the next Batch. It is sturdy in Construction and easy to maintain.

PELLET MACHINE

This Machine is Used to make pellets of the Cattle feed according to the desired size which are easy to eat for the Cattles and also easy to feed and to take care of Quantiy.

Easy Maintenance

Precise Operation

Easy to operate

High quality materials

PELLET COOLER

Pellet Cooler is used to cool down the Cattle feed pellets storage able and packing able temperature by cooling it down evenly and in less time.

Sturdy Construction.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Saurav Goyal

- Address

- 11460/1,STREET NO.4,PARTAP NAGAR,INDUSTRIAL AREA-B ,LUDHIANA-141003

- Product Category

- Oil Pressers

- Year Established

- 1992

- No. of Total Employees

- 51-100

- Company introduction

-

SHREEJI EXPELLER INDUSTRIES IS A LEADING MANUFACTURES & EXPORTERS OF OIL MILL MACHINERY, OIL EXPELLER & OIL EXTRACTION MACHINERY

Shreeji Expeller Industries has been established in 1992 by Sh. Naresh Kumar Goyal. It is an internationally reputed manufacturer and exporter of all type of oil extraction machinery and components necessary for oil extraction plants, oil mills, oil refinery plants and bio-diesel plant production houses. The company delivers the top level solutions to clients for every aspect of machinery including designing and erection to commissioning and maintenance.

The firm is an ISO 9001-2008 certified company, delivering full range of services to oil seed processing, oil extraction and related product industries. The company is also affiliated with Engineering Export Promotion Council of India and other prestigious business organization.

Our Head Office is based in Ludhiana. The production unit carries trained technicians, quality control officer, determined working staff and the modern machinery. We have the advantage of being able to develop different models of Oil Expeller / Oil Screw Press, Filter Presses, Seed Cleaners, Boilers, Hammer Mill, Kettles ,refinery etc.

Crucial to every part of the process,our quality department checks the products at every stage ensuring our clients always get superior quality products. Our Machineries have a reputation of being robust in construction, superior in quality, versatile in nature and operationally profitable. Also our vastly experienced personnel provide training to customers operating staff.

At Shreeji Expellers, we are constantly progressing with state-of-the-art infrastructure , a proficient team, efficient services and on-schedule delivery schedule. To maintain competitive edge in the markets, we have constantly been upgrading our technology and our research and development department has been coming out with innovations and new solutions to address our clients’ requirement. Shreeji Expeller Industries ensures to offer superior quality products at most competitive prices in least lead time. Our company has been aiming to enrich Oil Sector through Our Machineries constantly winning the trust and respect of the national and international community.

History:-

Mr. Naresh Kumar Goyal with experience in the industry since 80s Establish Shreeji Expeller Industries in 1992. Which began as a small family venture, based on a foundation of dedication, hard work and hope, grew in strength and purpose over the years.

Since than we are serving this Industry with our products and services. Our Machines can handle various oil seeds like Mustard, Canola, Rapeseed, Coconut, Soyabean, Sunflower, Cotton Seed, Jatropha, Palm seed, Groundnut, Corn Germ & Sesame and other Seeds and Nuts.

Shreeji Expeller is a company geared towards total quality management. This is a company which works on the principles of honesty, integrity, sincerity and dedicated to serve its customer’s interest.

Now, with the next generation Shreeji Expeller Industries will lead the way to the future of Oil Extraction Industry, enriching lives around the world with the Quality and most efficient ways of Oil Extraction.

Through our commitment to quality and constant innovation and respect for the planet ,we aim to exceed expectations and be rewarded with a smile.

- Main Markets

-

Angola

Angola

B.I.O.T

B.I.O.T

Bouvet Island

Bouvet Island

Burundi

Burundi

Cape Verde

Cape Verde

- Main Product

Related Products

Scallion Shredder

BRESSO OVEN

SHRINK WRAPPER

Rice pop machine, Korean rice cake machinery

Color Sorter (ZOOMT-192S)

India

India