Automatic Egg Grading and Packing Machine, Egg Grader

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- Genius Egg grader

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- egg grading, eggs, egg grading machine, egg conveyer

Eggtec Co., Ltd.

- Verified Certificate

-

17

| Product name | Automatic Egg Grading and Packing Machine, Egg Grader | Certification | - |

|---|---|---|---|

| Category |

Food Packaging

Other Machinery & Industry Equipment |

Ingredients | - |

| Keyword | egg grading , eggs , egg grading machine , egg conveyer | Unit Size | 7.5 * 0.0 * 8.6 m |

| Brand name | Genius Egg grader | Unit Weigh | 3000 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8433601000 |

Product Information

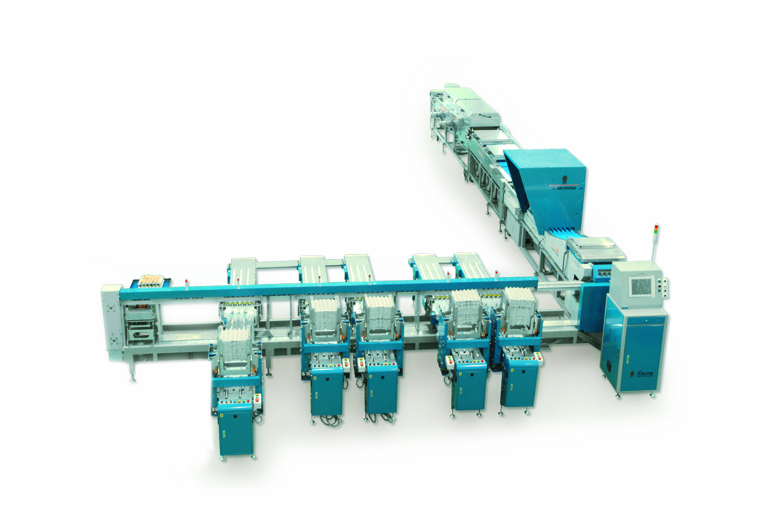

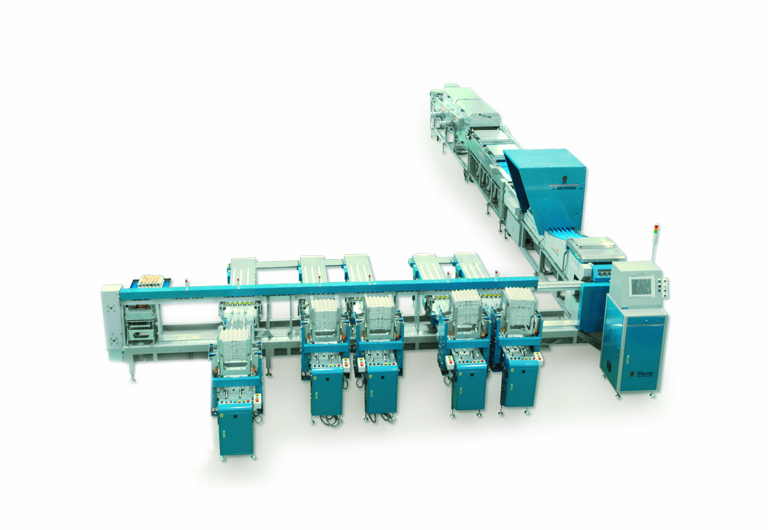

Genius Automatic Egg Grading and Packing Machines are the best choice for excellent works from grading to packing.

This range of Automatic Egg Grading and Packing System is designed with a sophisticated egg handling technology what makes it easy to process eggs in 1 or 2 transport conveyors in high speed.

The Genius Automatic Egg Grading and Packing system has been made to meet the customer needs: less human labor, time saving, easy operating, self maintenance, excellent egg processing, safety worry-free, A/S etc.

The Genius Automatic Egg Grading and Packing in-line capacity ranges from 25.000 to 70.000 eggs per hour.

The weight classification accuracy error is ± 0.3gf.

Models:

1. Genius B25K, B30K

⇒ This is the most economic egg grading and packing machine out of all models.

>> In-line capacity 25,000~30.000 eggs per hour

- Transport Conveyor: 1 channel

- Power supply 3Phases+neutral, AC380V, 50Hz/60Hz

- Weight 3.000Kg

- Number of Packers: 4~5

- Power consumption: 1,5KW (without option such as Washer & Dryer)

26KW (with Washer & Dryer)

- In-line row: 6 channels (lines)

- Grade: 5~8

- Width: 13,6 m x 6,6m x 2m (with Washer & Dryer)

5,8m x 6,6m x 2m (without Washer & Dryer)

2. Genius B35K

⇒This is the most effective, reliable and economical egg grading and packing machine.

It has a good compatibility with options.

>> In-line capacity 35.000 eggs per hour

- Transport Conveyor : 1 channel

- Power supply 3Phases+ neutral, AC380V, 50Hz/60Hz

- Weight 3.000Kg

- Number of Packers: 5~6 sets

- Power consumption: 1,5KW (without option such as Washer & Dryer)

28KW (with Washer & Dryer)

- In-line row: 6 channels (lines)

- Grade: 5~8

- Width: 7,6m x 6,6m x 1,6m (without Washer & Dryer)

16,6m x 7,6m x 1,6m (with Washer & Dryer)

3. Genius B60K

⇒B60K is a set of two BE30K model paired in two rows.

This model is considered as the most effective, reliable and an economical grader out of all.

It is seen as the best tool for saving time and reducing human labor as well.

>> In-line capacity 60.000 eggs per hour

- Tolerance: ± 0.3gf

- Transport Conveyor : 2 channels

- Power supply 3Phases + neutral, AC380V, 50Hz/ 60Hz

- Weight 7.200Kgf

- Packing lanes: 6 x 2lines

- Number of Packers: 8~10

- Power consumption: 6KW (without option such as Washer & Dryer)

52KW(with Washer and Dryer)

- In-line row: 6 channels (lines)

- Grade: 5~8

- Width: 19,8m x 11,6m x 1,6m (with option such as Washer & Dryer)

14,2m x 11,6m x 1,6m (without Washer & Dryer)

4. Genius B70K

⇒This model is a set of two B35K model paired in two rows.

The eggs are sorted in 12lines at the same time in a very safe and coordinated process.

>> In-line capacity 70.000 eggs per hour

- Tolerance: ± 0.3gf

- Transport Conveyor: 2 channels

- Power supply 3Phases + neutral, AC380V, 50Hz/60Hz

- Weight 7.200Kgf

- Packing lanes: 6 x 2lines

- Number of Packers: 10~12

- Power consumption: 6KW (without option such as Washer & Dryer)

56KW(with Washer and Dryer)

- Grade: 5~8

- Width: 19,8m x 11,6m x 1,6m (with option such as Washer & Dryer)

14,2m x 11,6m x 1,6m (without Washer & Dryer)

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Yoon Taeg-Jin

- Address

- 77 techno3ro Yu seong gu Daejeon Korea

- Product Category

- Other Machinery & Industry Equipment

- Year Established

- 1986

- No. of Total Employees

- 1-50

- Company introduction

-

Established in 1986, Eggtec Co., Ltd. is a privately held manufacturer of egg grading systems. We specialize in developing and sales of egg grading systems.

We employ more than eight employees, including 6 high-skilled engineers and two QA staff.

Jun, 1986: Establishment (Daechang, Ltd -Machine part sales business)

Jan, 1990: Change of company name (Daechang, Ltd -> Semyung Industrial Co, Ltd.)

Aug, 2000: Change of company name and business type (Eggtec -manufacturing business)

Mar, 2002: Selected as clean business site (Korea Occupational Safety & Health Agency)

Aug, 2003: Selected as prospective small and medium business (City of Daejon)

Jul, 2005: Selected as export prospective small and medium business(Small and Medium Business Administration)

Aug, 2005: Acquired KSA/ISO 9001certificate

Sep, 2005: Established exclusive research & development department (technology development office)

(Certified by Korea International Broadcasting Foundation)

Nov, 2005: Certified as the venture company of excellent technological assessment

(Korea Technology Credit Guarantee Fund)

Dec, 2005: Changed corporate name (Eggtec -> Eggtec Co, Ltd)

May, 2006 : Selected as the business specialized in component materials

(Ministry of Commerce, Industry and Energy)

May, 2007 : Nano silver egg washer & dryer Eggzen Ag2500

- Main Product

Related Products

Enterpack Heater _EHQ series

Airless Pump (Ratio 63:1 Airless Pump)

High Speed Door_ KAD-2000, cua cuon nhanh

AIS3000 HD

Instantaneous Heating Module (IHM for Bidet)

South Korea

South Korea