Micro Coil bonding/Diffusion Fusion Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery & Industry Equipment

Ace Co., Ltd.

- Verified Certificate

-

11

| Product name | Micro Coil bonding/Diffusion Fusion Machine | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | bonding machine , micro coil bonding machine , micro coil diffusion fusion machine | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

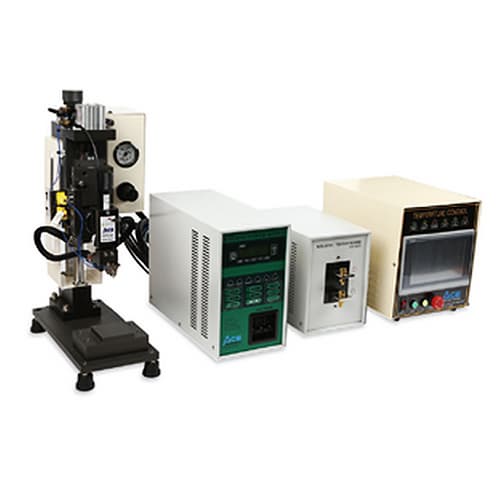

Micro Coil bonding Machine / Micro Coil Diffusion Fusion Machine

│ DESCRIPTION │

- Diffusion is a process where one material is transported to the other with less concentration by atomic motion based on time and temperature.

- The term “Diffusion Bonding(Fusion)” means the process of applying heat and pressure to promote atomic transportation to bond materials together.

Micro Coil Diffusion Fusion Machine Micro coil diffusion fusion machine applies heat and pressure created by the chip’s own thermal activities to bond steel wires together without using the conventional method of welding that uses electrodes. This innovative method allows users to fine-tune the load and horizontal/vertical accuracy and improve the quality of their product.

│ FEATURES │

- It does not compromise the strength by not melting base metal.

- No bonding(fusion) material is needed.

- There is no need to peel off coil (ø0.025mm ~ ø0.09mm).

- It does not change the substance and structure of interface.

- It has better thermal resistance and bonding(fusion) strength than conventional methods.

- Base metal is not subject to transformation due to heat.

- You can form the interface freely.

- It facilitates automation process.

│ SPECIFICATION │

Model |

Fuction |

|

Power Supply Unit

|

Using the Voltage |

AC single-phase 220V ± 10% 50/60Hz |

Operating Temperature |

0 ℃ ~ +50 ℃ Humidity : 90% |

|

Rated Power |

1.0 KVA |

|

Maximum Output |

1,000A (HCT-100T terminal output) |

|

Work Timer Chart |

1) SQUEEZE : 0 ~ 999m/sec |

|

|

2) UP SLOPE 1 : 0 ~ 49m/sec (HEAT 1 inclusive) |

|

3) HEAT 1 : 0 ~ 999m/sec |

||

4) DOWN SLOPE 1 : 0 ~ 49m/sec |

||

5) HOLD : 0 ~ 999m/sec |

||

Control Frequency |

4kHz |

|

Control Mode |

1 times the current detection, the constant current control of the PWM mode |

|

Cooling Method |

Air cooling |

|

Maximum Usage |

10% (1,000A Time) |

|

Transformer Output |

MAX (A) 1,000A, no load6.0V |

|

Output Conditions(MODE) Setting |

120 MODE (A) / Preheating function (B) |

|

Current Setting |

CURRENT 1 : 100 ~ 1,000A |

|

Size (mm) |

160(W)×270(H)×375(D) 160(W)×225(H)×300(D) |

|

Weight (Kg) |

8kg |

|

Temperature Controller |

Using the Voltage |

AC single-phase220V ± 10% 50/60Hz |

Operating Temperature |

0 ℃ ~ +50 ℃ Humidity: 90% |

|

Rated Power |

50W |

|

Use Models |

ACI 1500(A) / ACI 1500(B) |

|

Work Timer Chart |

1) T1 Start Delay Time : 0 ~ 9.9 sec |

|

|

2) T2 Out time : 0 ~ 9.9 sec |

|

3) Up Down Signal |

||

4) Out Up Signal |

||

5) END Signal Delay Time : 0 ~ 9.9 sec |

||

6) In Put : See Signal Table |

||

Cooling Method |

Air cooling |

|

Input /Output Contacts |

In 18P Out : 20 P |

|

Size |

230(W)×275(H)×325(D) |

|

Weight |

5.4kg |

|

Head Unit

|

Use the Voltage |

AC single-phase 220V ± 10% 50/60Hz |

Operating Temperature |

0 ℃ ~ +50 ℃ Humidity : 90% |

|

Use of Pressure |

4 bar ~ 6 bar |

|

Pressure Device |

0.4kg ~ 7kg (See Table) |

|

Angle Adjusting Means |

0 to 8 degrees |

|

Up and Down Height Adjustment |

100mm (nose fixed distance) |

|

Move Up and Down Distance |

0 ~ 10mm |

|

Fixed Fixture Package |

X: 5mm Y: 5mm (Manual) |

|

Size |

150 (W) X 320 (H) X 530 (D) |

|

Weight |

4.8kg |

|

Heater Chip |

Determined according to the shape of the product |

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Hyeoncheol Ahn

- Address

- 8,321 Street, shihung1daro,Shihung-si, kyounggi-do, Korea

- Product Category

- Mechanical Accessory & Parts Processing,Power Transmission Parts

- Year Established

- 1999

- No. of Total Employees

- 1-50

- Company introduction

-

Do you still use spot welding or a peeling and soldering process after winding? You can improve your process and achievea disconnection rate of 1ppm using the precision fusion machine (Φ0.025mm - Φ0.09mm) as well as make your facilities more eco-friendly and stable. Our innovative Diffusion Fusion Machine will also maximize your productivity beyond your expectations.

Our Company micro coil thermal bonding(fusion) technology

has been further improved by ACE Co., Ltd. and recognized by major global companies over the years for its high standard of innovation and quality

- Main Markets

-

South Korea

South Korea

- Main Product