Vacuum insualtion panel

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Heat Insulation Materials

Vacumn Insulation Tech CO.,LTD

- Verified Certificate

-

11

| Product name | Vacuum insualtion panel | Certification | - |

|---|---|---|---|

| Category | Heat Insulation Materials | Ingredients | - |

| Keyword | thermal insulation , thermal insulation panel , vacuum insulation | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

.

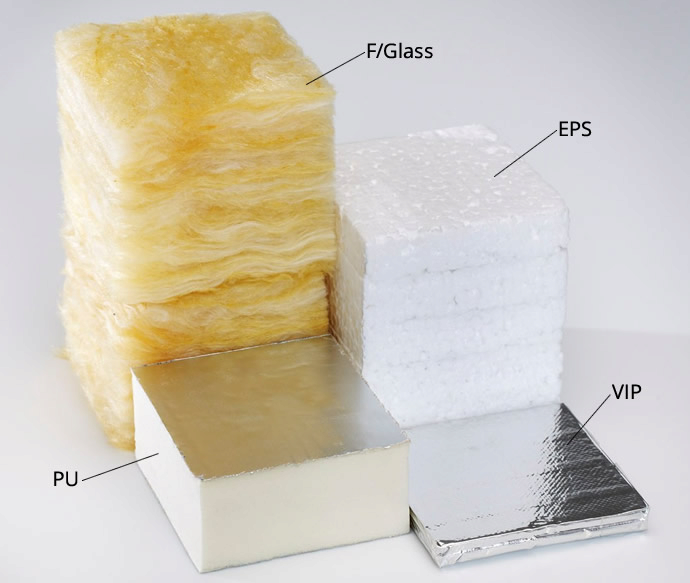

insulation core material: Glass wool

Density 100-300 kg/m3 thermal conductibility0.0025W/m.K Average fibe dia2.5um(>40%)

- Compressive Strength: 0.14MPa - 0.25MPa

- Thickness: 10 - 35mm

- Maximum Dimensions: 2000 x 1650 x 35mm ,

- Core Material: Superfine Glass wool

- Thermal Conductivity: Less than 0.0025w/(m. K) (under standard environmental condition: Ambient temperature 24degree centigrade, relative humidity 50%, 19.77mm

- Density: About 230kg/m3

- Operating Ambient: -50 ~ 150 degree centigrade

- External Tolerance of VIP: 1mm

- Packing: Carton with foam and air bubble film

- Service life: 10-15 years under standard environmental condition

calculated by accelerated life test, based on theoretical deviation

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Sun Woo Park

- Address

- N201, Jooyoung BLD., 1030-8, Seo-Gu, Daegu, Korea

- Product Category

- Heat Insulation Materials

- Year Established

- 2013

- No. of Total Employees

- 1-50

- Company introduction

-

Vacumn Insulation Tech CO.,Ltd company team has developed, designed and manufactured vacuum processing and packaging machines since it's foundation in 2013. Custom-made vacuum packaging machinery for high performace thermal insulation panels.

Energy costs have risen dramatically in recent years, and vacuum insulation panels are a proven application that offers nearly ten times more energy-saving insulation than standard materials. Our equipment forms the basis to produce these VIP’s to the highest standards.

The VIT company is able to deliver all necessary equipment for VIP production.

We have expanded our original core business of vacuum chamber packaging machine system to VIP panel production having thermal conductivity below 0.0025 and life span of over 15 years.

Our products are marketed now only in domestic market under the registered brand name the VIT company.

- Main Markets

-

China

China

Japan

Japan

Viet Nam

Viet Nam

- Main Product

Related Products

SH KOREA Heating Film SH310

No-Fire and Non - Flammable Tapes

PU PIR metal sandwich panel

SH KOREA Heating Film

SH KOREA Heating Film SH303

South Korea

South Korea