SCR catalyst regenerator and regeneration

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- catalyst, regeneration, scr, selective catalytic reduction

- Category

- Other Environmental Products

Daesung Hi-Tech

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Manufacturer

- Verified Certificate

-

11

| Product name | SCR catalyst regenerator and regeneration | Certification | - |

|---|---|---|---|

| Category | Other Environmental Products | Ingredients | - |

| Keyword | catalyst , regeneration , scr , selective catalytic reduction | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

1. Company Overview

2. Item descriptions

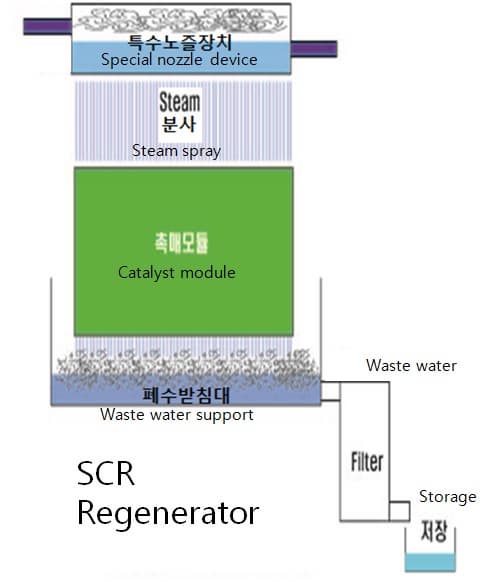

1) Item: SCR Catalyst regenerator and SCR catalyst regeneration service.

2) What is the SCR Catalyst?:

It is the essential material for process of SCR(Selective Catalytic Reduction) equipment system. In the SCR process, nitrogen oxides are transformed into harmless nitrogen and water by reaction with SCR catalyst and a reducing agent such as ammonia(NH3). With SCR equipments and SCR catalyst, thermal power plants can reduce nitrogen oxide emission.

3) Why SCR catalyst regeneration is necessary?:

SCR catalyst cannot be used permanently. It has 3~4 years of life time period. To maintain the performance of SCR process, used SCR catalyst has to be replaced, and it causes the maintenance cost to rise. However, used SCR catalysts is possible to be regenerated. It is very useful to reduce SCR equipments' maintenance cost.

4) Regeneration performance and available number to regenerate:

More than 80% of original performance is guaranteed after regeneration. It is possible to regenerate twice.

5) Performance data in South Korea:

Total 1,126 modules of SCR catalyst (roughly $ 15,764,000) at the 5 different thermal power plants are regenerated from July 2010 to September 2013. (KEPCO - Korea Electric Power Corporation, POSCO - Pohang Iron & Steel Company Limited)

6) SCR catalyst regeneration service

Also, we are handling SCR catalyst regeneration service. You don't have an interest to buy SCR catalyst regenerator but still need to regenerate SCR catalysts? Just contact us now. We can provide a service to regenerate SCR catalysts.

7) How can we provide SCR catalyst regeneration service

Our SCR catalyst regenerator is a moving equipment. We can go to any place you need. We will send out our SCR catalyst regenerator and technicians to the place where the regeneration is necessary. It is consist with 40ft of 2 to 3 containers however the size of container will be up to the daily capacity to regenerate as you will request us. The only thing you need is the business plan to regenerate SCR catalyst or has connection to the person who needs to regenerate catalysts. We will handle rest of things such as technical issue, equipment, manpower and regeneration work.

3. Profitability:

Example)

If there are 982 cubic meter of SCR catalysts at the thermal power plant,

Cost to replacing SCR catalysts is $7,074,000

However, cost to regenerating SCR catalysts is $3,500,000

You can save 3,574,000, if you use SCR catalyst regenerator rather than buy new SCR catalyst (51% of cost saving).

Environmental issue, especially air

pollution became a serious problem in nowadays. To reduce air pollution, SCR equipment

can be a useful solution for thermal power plants or factories. However, cost

to buy new catalysts is not a simple problem. It's a headache for power plants'

and factories' managers. They are looking for the way to reduce cost of SCR

catalysts, and this SCR catalyst regenerator can be a solution. That means, this

equipment can be a way to make money, if you own it.

Do you have any connection to the thermal power plant or a factory? Are you planning new type of business? This SCR catalyst regenerator can be a solution. Our SCR catalyst regenerator is a moving equipment. If you have it, you can go any thermal power plant or factory to regenerate SCR catalysts. Making money by SCR catalyst regenerator is not a dream! Also, we provide the service to regenerate SCR catalyst too. Are you a manager of a thermal power plant or a factory and looking for the solution to reduce cost of SCR catalyst? Just contact us now. We can provide a solution.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Chung jinhan

- Address

- 1707 Anam Tower, 311 Teheran-ro, Gangnam-gu, Seoul, 135-565, Korea

- No. of Total Employees

- 101-500

- Company introduction

-

Daesung Chemical is an automobile parts producing company specialized in rubber products. Since 1987, we have produced reliable rubber grommets. The quality of our products are proven by SQ certifications from Hyundai-Kia Motor Company. We are holding five different SQ certifications such as rubber, harness, injection, electrode/electronic and welding. Also, we are a distributor to trade environmental equipment which is SCR(Selective Catalytic Reduction) catalyst regenerator, and we are an agency to regenerate SCR catalysts. Since 2005, Daesung Chemical has produced ABS Wheel Speed Sensor and has produced Door Handle Sensor (for smart key) since 2008. In addition, we won Best Quality Supplier Award from Continental, and also won Technology Award from Choong-Nam Province in 2011. Daesung Chemical has production lines in Cheonan and Pyungtaek in South Korea, and Qingdao in China.

2010 - 25,200,000 USD

2011 - 33,900,000 USD

2012 - 33,200,000 USD

2013 - 39,300,000 USD

Estimated in 2014 - 40,300,000 USD

- Main Product

__2.jpg)