Floor Heating X-L Pipe

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- ENERPIA

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Home Heaters , Flooring & Accessories

ENERPIA Co., Ltd.

- Verified Certificate

-

17

| Product name | Floor Heating X-L Pipe | Certification | - |

|---|---|---|---|

| Category |

Home Heaters

Flooring & Accessories |

Ingredients | - |

| Keyword | floor heating , floor heating tube , heat transfer medium , x-l pipe | Unit Size | - |

| Brand name | ENERPIA | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

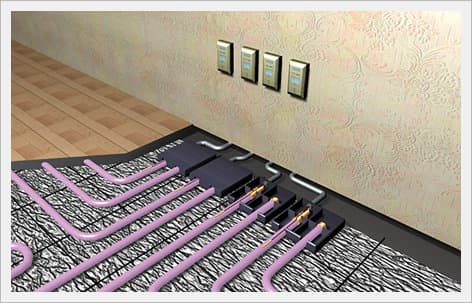

What is X-L PIPE HEATING SYSTEM?

It is an innovative heating system that uses heat and increased pressure generated by Heat Transfer Medium by heating the sealed X-L PIPE without boiler, in which water or other fluid is heated and water circulation motor which pumps water circulated in the PIPE.

It is the innovative high energy efficient floor heating system that has no heat loss and achieves 30°C rise effect in temperature. Our patented pressure absorbing device absorbs too much internal pressure and also the heat transfer medium and carbon tissue absorbs the electromagnetic waves for a healthy life.

Nucleate Boiling phenomenon: The process of forming steam bubbles within liquid in micro cavities adjacent to the wall if the wall temperature at the heat transfer surface rises above the saturation temperature while the bulk of the liquid is sub cooled. The bubbles grow until they reach some critical size, at which point they separate from the wall and are carried into the main fluid stream.

Benefits of Heating X-L Pipe System

- Economic

-No heat loss

-Accumulates of heat

-HIgh efficiency (Low electric power consumption)

-Low installation expenses - Safety

-Water leakage prevention

-Non electromagnetic waves

-Clean energy - Functional

-Traditional floor heat

-Sectional heat / Whole floor heat

-Well-being - Durable

-Cold lead installation and safety value for over pressure

-Long lasting

-Low temperature resistant - Easy & Convenient

-No space for boiler

-Good customer service(Warranty)

-Easy to use

-Easy heating system change(Electric X-L PIPE) - Various way

-Accommodations, Schools, Vavation facilities

-Hospital, Post-delivery Care Center, Church

-REstaurant, Green house, Swimming pool, Factory

CONDITIONS OF ELECTRIC X-L PIPE

Pressure absorbing device:It absorbs the internal pressure caused the Nucleate Boiling.

Double Coated Electric Wires:Since the conductor and the electric wire processing affect on product life and its function, make sure to read the followings.

- Conductor : 7 Strained Nickel - Chrome Coil

- The First Coating : Silicon Rubber coating that can stand very high temperature(270ºC) and has excellent insulating quality.

- The Second Coating : Heat resistant Teflon rubber coating that is water resistant and chemical resistant.

(Temperature resistance : 400°C)

Heat Conducing Medium: They should not freeze at twenty degrees below zero.

Hearmless to Human Body

Electromagnetic waves are absorbed by itself.

Cable

Cable should not exceed 20W/m.(According to Clause 5, Article 225 of Electric Installation Regulations. "The temperature

of Electric wires should not exceed 80°C" and/or "Internal Temperature of X-L should not exceed 80°C")

Specifications of Heating X-L PIPE

Application of Heating X-L Pipe

Pressure Test of X-L Pipe

Installation Procedure

| 1. Heat Insulating Material Silver insulator on the aerated concrete or styrofoam. |

2. Fix Wire mash. | ||

| 3. Set a inspecting box which is same height with the decorative design. |

4. X-L PIPE Start from the inspect box to return the END CAP. (The distance between cables : 200~250mm) | ||

| 5. Install the Temperature Sensor by binding to X-L pipe Temperature sensor for humid environ-ment at the exothermic. |

6. Cover the Inspecting Box Do not come in when plastering. | ||

| 7. Install Thermostat IN : Connect to the outlet plugging. / OUT : Connect to the cable. (Pay attention to the insulation and dampproofing) |

8. Test of Exothermic Check if the correct resistance and current run using the tester after finishing installation. | ||

| 9. Finishing Mortar Plastering 30~40mm thickness depends on the types of plastering. |

10. Finishing Materials Install finishing materials and inspecting Box. |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Ja hyung Lee

- Address

- Hwawon-Eup, Samunjin-Ro,#349-13, Dalseong-gun, Daegu, Korea

- Product Category

- Wires & Cables

- Year Established

- 2007

- No. of Total Employees

- 1-50

- Company introduction

-

The world's best in floor heating system, ENERPIA, has manufactured and developed materials and products which are Eco-Green and safe energy systems. As the prevention of global warming and the control of carbon emission in addition to securing the natural energy resources have become the worldwide common issues, we have been devoting ourselves to the importance of heating system and energy conservation. This system can reduce heating cost, save energy and prevent global warming.

- Main Markets

-

Chile

Chile

China

China

Hungary

Hungary

Japan

Japan

Kazakhstan

Kazakhstan

Kyrgyzstan

Kyrgyzstan

Macedonia

Macedonia

N.Zealand

N.Zealand

Poland

Poland

Russia

Russia

Saudi Arabia

Saudi Arabia

Ukraine

Ukraine

Uzbekistan

Uzbekistan

Viet Nam

Viet Nam

- Factory Information

-

Daegu Factory

- Main Product

South Korea

South Korea