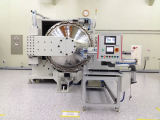

Wood dryer

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- dryer equipment, wood dryer, wood drying machine

- Category

- Drying Equipment

Guangzhou Greendrier Energy Equipment Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | Wood dryer | Certification | - |

|---|---|---|---|

| Category | Drying Equipment | Ingredients | - |

| Keyword | dryer equipment , wood dryer , wood drying machine | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Guangzhou Greendrier Energy Equipment Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

12

- President

- Mr.shi

- Address

- Room B501-B502,No. 08,Kesheng Road,SCI-TECH Park,No. 1633,Beitai Road,Baiyu District

- Product Category

- Electronic Products,Machinery & Parts

- No. of Total Employees

- 51-100

- Company introduction

-

Guangzhou Greendrier Energy Equipment Co., Ltd. is specialized in product development, manufacture, market management and service for dehumidification drying. Which is a key supported industry by the government and located in Guangzhou Hi-Tech Industrial Development Zone. Within the development strategy of independent innovation and scientific-technical progress, we has developed lots of new products in energy-saving dehumidification drying with our own Intellectual Property. Especially for the new heat pump dehumidification dryers and swimming pool dehumidification heat pump products, We have obtained more than 10 national patents. Our independent innovative technologies contained the double effect/triple effect regenerative cycle heat pump dehumidification drying technologies, and the new temperature-humidity air conditioner equipment which controlled independently. Our technologies stay ahead in the same industry. Like the swimming pool dehumidification heat pump regenerative dehumidification technology, fresh air pre-dehumidification technology, discharge air cold and heat recovery technology, refrigerant overcooling and overheating regeneration technology, and modular control technology. We are dedicated to the development, application and popularization of new energy-saving and emission-reduction swimming pool energy utilization technologies. Owned perfect product marketing and technical service platform. At present, we have got seven series products of over 40 specifications' products, including swimming pool dehumidification heat pumps, double effect heat pump dehumidification dryers, triple effect heat pump dehumidification dryers, etc., which is popular with many consumers by our matured craftsmanship and advanced technologies. Based on the management aim of "Honesty, Novelty, Quality and Supreme" and the belief of "Focus on People, Scientific and Technical Innovation", We are committed to the "energy-saving, environmental protection" issue, to create the well-known brands in this industry by our "High, Precision and Frontier" tech talent.

- Main Product