AAC Production Line,Light Weight Block

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Home & Kitchen

Henan LanJi Machinery Manufacturing Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

14

| Product name | AAC Production Line,Light Weight Block | Certification | - |

|---|---|---|---|

| Category | Home & Kitchen | Ingredients | - |

| Keyword | aac block production line , aac block , light weight block | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

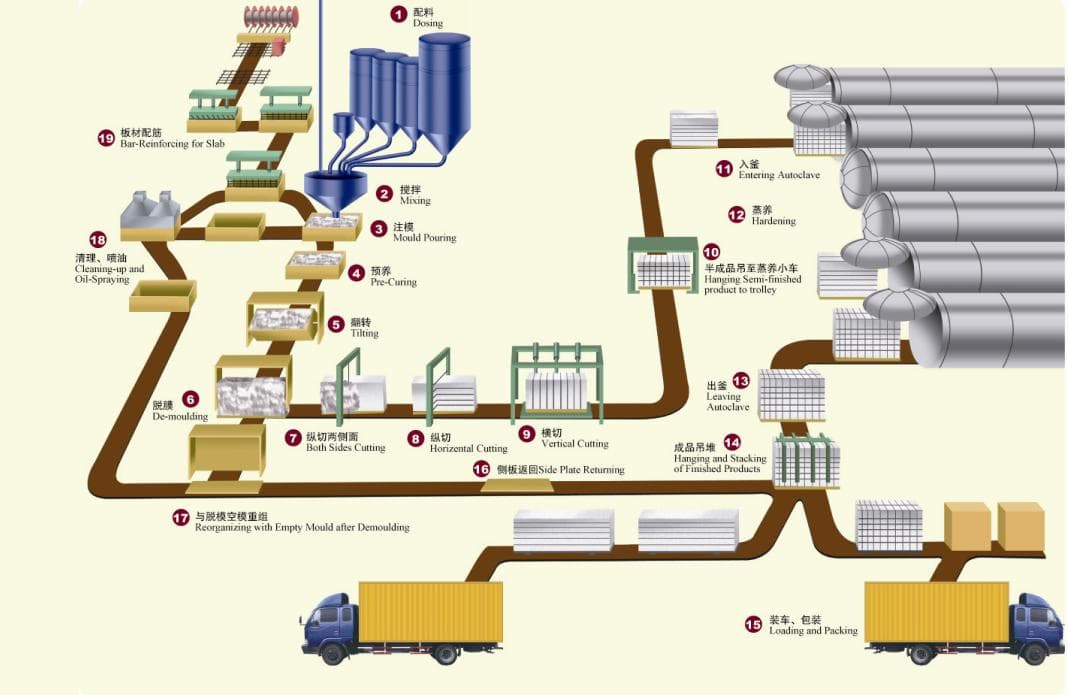

Main Equipments in AAC Production Line

Material-milling Equipments: 1 Crusher: Lime, gypsum, and such kind of bulk material need to be crushed as the first step in AAC Plant. 2 Miller: The AAC material must be fully grinded in order to make better reaction. Ball Mill is used widely, it has two types: dry and wet, can be chosen upon requirement.

Material Metering Equipments: Computer Control Automatic Metering System is commonly used as measurement of raw materials.

Material mixing and casting equipments: Mixer, it’s the slurry mixing machine, also is slurry casting machine.

Cutting Machine: the AAC blank is formed after casting and pre-curing, as the size is too large, it must be cut to achieve the required product size.

Autoclave: Autoclave is a device for silicate hydration products to get physical and mechanical properties.

Boiler: the boiler supports for the autoclave and pre-heat furnace and other facilities with heat.

Auxiliary Equipments: 1 Mould Frame, Mould Bottom and Mould Car, they composed together to form the Casting Mould, which is the main forming equipments in AAC Production Line. 2 Hardening Cart, Ferry Cart and Hangers, they must be equipped as auxiliary equipments in autoclave curing system.

The Performance Advantage

Lightweight: Porosity achieve 70% to 85%, volume density is generally 500 ~ 900kg/m3, as 1/5 of general concrete the 1/4of clay, the 1/3 of hollow brick, and similar with wood can float in water. It can reduce building weight, reduction in the cost of integrated building.

Fireproof: Most of the major raw materials is inorganic materials, so it has good fire resistance, and do not emit harmful gases when meet fire. Fire 650 degrees, as a refractory material, the thick up of 90mm walls can reach to 245 minutes fire resistance, 300mm thick up wall can reach to 520 minutes fire resistance.

Sound insulation: Due to a unique porous structure, so it has a sound absorption capacity. The sound absorption capacity can reach of 10mm thick wall up to 41 db.

Insulation: As the material inside has a large numbers of the pores and porous, which has a good thermal insulation properties. The Thermal conductivity is 0.11-0.16W/MK, as 1/4-1/5 of brick. Typically, the insulation effect of 20cm thick aerated concrete wall is equivalent to 49cm thick solid brick walls ordinary.

Permeability: Result of material by the composition of many independent small pores, the moisture absorption is slow, in the volume of absorbent is 5 times of clay saturation do. When used in the bathroom, the wall can be treated to interface directly paste tiles.

Anti-seismic: The same building structure, improve the two seismic than the brick level.

Pro-environment: Manufacturing, transportation, all use the process of pollution, to protect arable land, saving energy, is one kind of a green building material.

Durability: material strength is stability, in the specimens tested after one year of atmospheric exposure; the intensity increased by 25%, and remained stable after ten years.

Shortcut: it has good machinability, can be sawed, planed, drilled, nailed, and available appropriate as bonding of adhesive material, so create favorable conditions for building construction.

Cost-saving: An integrated lower cost than using more than 5% of solid clay bricks, and can increase the usable area, greatly enhance the utilization of floor space.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Henan LanJi Machinery Manufacturing Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

14

- President

- Mr.Sun

- Address

- Crossroad of Xi sihuan road and Huagong road

- Product Category

- Machinery & Parts

- No. of Total Employees

- 101-500

- Company introduction

-

Henan LanJi machinery manufacturing Co., LTD. is a jiont-stock mining machinery manufacturing enterprises

integrated in scientific research, production and marketing. It is located at the Hig-Tech development Zone Zhengzhou,China with an area of 80 thousand square meters .Equipments are more than 200 pieces, including large and medium sized metal processing, riveting and installing equipments.Engineers are more than 50 persons.The leading products of our company include: beneficiation equipment,crushing equipment,sand making equipment,cement equipment, Aerated concrete block production line.Widely used in the industries of metallurgy,mining,railway,high-way,building materials,refactory,ceramic industry,etc. Complete set of ore beneficiation equipment include ball mill,crusher,magnetic separator,flotation machine,spiral classifier ,rotary dryer , widely used to separate the non-ferrous metals such as iron ore,copper ore,gold ore,lead&zinc,manganese ore,molybdenum ore,etc.and the Non-metallic Minerals like fluorite,quartz,etc.Jaw crusher,impact crusher,sand making machine,vibrating screen,sand washing machine,belt conveyor are widely used for the airport,railway,high-way,road,buliding,etc.Aerated concrete block has been one important part to the new buliding materials.We can provide program design,process flow design,standard and non-standard design for clients.

Our company has passed ISO9001-2008 quality certificate,the produce sell well to domestic and abroad,Such as South Asia,Russia,Central Asia,Africa,Middle-east,etc.

Our company's tenetis "Advanced technology,quality first,sincere service,reputation first".We can ensure our clients without worry after buying by one set of complete after-sales service and quality-tracking system.

We sincerely hope to cooperate with the clients from all over the world to achieving mutual benefits and promotion,and touching our theory through cooperation!

- Main Markets

-

Afghanistan

Afghanistan

Angola

Angola

Argentina

Argentina

India

India

Indonesia

Indonesia

Malaysia

Malaysia

South Korea

South Korea

- Main Product