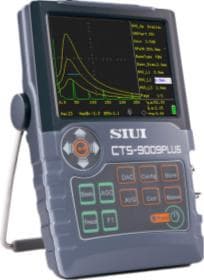

Digital Ultrasonic Flaw Detector CTS-9009PLUS

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- SIUI

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- flaw detector, ndt

- Category

- Machinery & Parts

Shantou Institute of Ultrasonic Instruments Co., Ltd

- Verified Certificate

-

11

| Product name | Digital Ultrasonic Flaw Detector CTS-9009PLUS | Certification | - |

|---|---|---|---|

| Category | Machinery & Parts | Ingredients | - |

| Keyword | flaw detector , ndt | Unit Size | - |

| Brand name | SIUI | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Features

High Performance: With adjustable spike & square wave pulser up to 500V and operation frequency up to 20MHz, this system can achieve precise flaw detection from thin plates to large forged pieces.

Rich Functions: The system features functions such as auto gain control, peak memory, DAC, AVG/DGS, probe frequency measurement, cineloop, curved surface correction, AWS, API and ports like USB, Ethernet and VGA.

Environmental Protection: The system is designed based on IP65 (Optional IP67) standard, suitable for complex industrial flaw detection environment.

Super-low Consumption: The configured Li-polymer battery can support up to 7-hour continuous operation.

Easy Operation: There are just a few concisely-defined keys, easy to be operated with only one hand.

Compact & Portable: The whole unit weight (battery included) is approx. 1.25kg, suitable for aloft and field work.

Function

Operating frequency range: 0.5~20MHz, highlighting advantages of high sensitivity and broadband.

Adjustable pulse width square wave transmission is up to 500V.

80 ~ 2000Hz PRF with 10 steps adjustable: avoid reverberation signals during flaw detection.

The convenient and useful probe spectrum analysis function enables the users to know the probe waveform, spectrum and center frequency, resulting in more precise flaw detection evaluation.

Measure crack height by edge peak echo method.

Max. sampling rate 240MHz; Measurement resolution 0.1mm.

RF (Radio Frequency) echo display: good to thin-wall material measurement, academic research or qualitative analysis.

The DAC curve works with echo compare function, making echo quantification of different distances and amplitudes more convenient.

The AGC (auto gain control) function, together with peak echo and image freeze function, help quickly identify the flaw highest echo, enabling efficient flaw detection.

Advanced thickness measurement function available.

Featured with AWS D1.1/D1.5 and API 5UE evaluation standards.

The gate magnifier function magnifies the echo area within the gate to the whole screen display.

Up to 500 sets of curve and waveform can be saved for various workpieces and flaw detection standards.

Application

VGA Video Output Function

VGA Video Output function makes it easier for you to have a presentation or a flaw detection demonstration.

Detection on Large Forged Pieces

Adjustable pulse width square wave transmission up to 500V. High penetration and large detection range to achieve detection on large forged pieces and coarse crystal material.

Probe Spectrum Analysis Function

The probe waveform, spectrum and center frequency of the probe can be measured precisely by capturing echoes

AVG/DGS Curve

AVG/DGS curve will be auto created by taking a known flat-bottom hole or large flat-bottom echo for reference.

DAC Curve

The DAC curve function brings easier and more convenient flaw evaluation.

Dynamic Cineloop

Internal finite echo recording or external infinite USB dynamic recording function to achieve recording full scanning process.

Echo-to-Echo Thickness Measurement

With thickness measurement function module, the system can achieve a variety of thickness measurement modes.

Ethernet Communication

With network communication, the system can be connected to a PC directly via 100Mbps Ethernet, so as to achieve real-time display and remote control.

Reporting

Detection echoes, curves or parameters may be losslessly stored to a PC via 100Mbps Ethernet, facilitating report editing and data management. Screenshot and detailed info can be transferred into Microsoft Word for customized reporting.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Mr.Li

- Address

- #77,Jinsha Road, Shantou 515041,Guangdong,China

- Product Category

- Machinery & Parts

- Company introduction

-

Shantou Institute of Ultrasonic Instruments Co., Ltd. (SIUI), a shareholding company headquartered in Shantou city, southeast of China, is an ISO certified company and has been dedicated to R&D, manufacture and sales of Ultrasonic Flaw Detectors for more than 30 years. We keep upgrading our technology and strive to serve our customers with reliable quality, high performance and competitive price NDT products. All the products available are EN compliant and CE marked, which ensures high quality. Our products can be applied in many ultrasonic flaw inspection fields, such as machinery, metallurgy, railway, shipbuilding, aircraft and building. SIUI will keep upgrading our current product lines and deliver better solutions for ultrasonic testing.

- Main Markets

-

South Korea

South Korea

- Main Product

Related Products

UIM2901-5A MACH3 break out board for CNC

MECHANICAL PACKING, GLAND PACKING, YARN ROPE PACKING

Torrington Bearing

Modbus Device Recorder

Date Pin (Date Core)

China

China