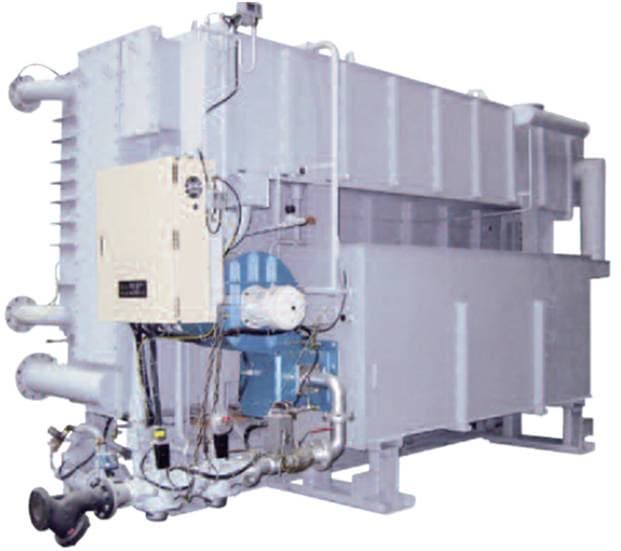

Absorption Chiller Heater

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- ZEPHYRUS

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- absorption

Shinsung Engineering

- Verified Certificate

-

12

| Product name | Absorption Chiller Heater | Certification | - |

|---|---|---|---|

| Category | Refrigeration & Heat Exchange Machinery | Ingredients | - |

| Keyword | absorption | Unit Size | - |

| Brand name | ZEPHYRUS | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

If you need moe product's information, please visit below website;

www.ishinsung.com

Shinsung Engineering has more various absorption chillers as below

> Double-Effect Steam Absorption Chiller

> Hot water Driven Absorption Chiller

> Single Effect Double Lift Hot Water Driven Absorption Chiller

> Hybrid Dual Absorption Chiller-Heater

* Direct Fired Absorption Chiller & Heater

COP 1.35 ~ 1.38 (Super High Efficiency Model)

Excellent Performance with More Energy Savings, Excellent Efficiency at Much Lower Cost.

At Shinsung Engineering, basing ourselves in cooling technology and know-how acquired over many years, we put into practice our latest proprietary technology. Through the use of large chilled water/cooling water temperature differential adaptability and provision of a high-functionality microcomputer as a standard control panel, superior reliability and durability are realized, while achieving running efficiency. As an item of new-age cooling equipment Shinsung’s one step advanced chiller contributes to the realization of total energy-saving and low cost in air-conditioning system.

High Efficiency Operation

In addition to the parallel flow system, Shinsung′s new proprietary flow technology (ACA flow technology) is employed in the cooling water system. Without increasing the chiller frame size, the adaptation to large chilled/cooling water temperature differentials has been made possible. Accordingly, energy-saving and low operating cost (by reduction of start-up and other operating costs) are achieved not only for the chiller but for air-conditioning as well.

Through high-efficiency heat exchanger, higher efficiency can be exerted

Through recovering heat loss of inner cycle, using Low temperature generator condensing refrigerant heat recovery unit, high efficiency is achieved. High efficiency and miniaturization are achieved through serial connection of a liquid heat exchanger, using a welding typed Plate heat exchanger favorable for high-efficiency and miniaturization, so as to ensure optimal Fluid Velocity even with less liquid volume. COP 1.35 ~ 1.38 (Super High Efficiency Model) 07 Shinsung Engineering 06 Large-Temperature-Differential System By using the large-temperature-differential system, the circulating volumes of chilled and cooling water can be reduced. The largetemperature- differential system reduces power needed for circulating air and water, because of reduced volumes of the draught from the air conditioner fan and of the circulating water from the chilled and cooling water pumps. In addition, it makes such facilities as air ducts and chilled/cooling water pipes smaller, and also reduces the initial cost for them.

4 Effects of Introducing Parallel Flow System

The parallel flow system technology has proven its high reliability over a long history of more than 30 years since hitachi developed the double effect absorption chiller.

Low internal pressure during operation

The internal pressure of the high-temperature generator depends on the concentration of lithium bromide in the low-temperature generator. With the parallel flow system, the weakest solution coming out of the absorber is fed to the high-temperature generator considerably lower than atmospheric pressure. As a result, the system can be operated in a cycle with a sufficient margin with respect to atmospheric pressure.

Energy saving

Because the parallel flow system divides the flow of solution in two to feed the two generators(high-temperature generator) with solution, the quantity of solution that is handled in the solution heat exchangers can be almost halved. Therefore, it is possible to greatly save energy by using a small heat exchangers. As a result, an additional energy saving effect can be realized with an uncomplicated reasonable design.

Because of its compact size, the whole unit can be carried in at once

Because it is unnecessary to feed solution from the high-temperature generator can be arranged diagonally beneath the main unit shell. This results in a smaller width of the whole unit. Therefore, the unit can be carried in and installed without being divided into pieces.

Stability and high reliability

The concentration of solution at the absorber inlet where the temperature is lowest is lower with a parallel flow system than with a series flow system, and sufficiently distant from the limit of crystal precipitation (the limit for solution to crystallize) Therefore, the system operates safely with no anxiety of crystallization. Because of its compact size, the whole unit can be carried in at once without being divided into pieces. Therefore, the reliability proved by strict air strict air tightness test in the fabrication plant is not degraded.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Park Dae Hui

- Address

- 1094, Hwagok6-Dong, Gangseo-Gu, Seoul-City, 157-927, Korea

- Product Category

- Dehumidifiers,HVAC Systems & Parts,Refrigeration & Heat Exchange Machinery

- No. of Total Employees

- 101-500

- Company introduction

-

Shinsung Engineering, which has led the new technologies of HVAC industry with its challenge and creative mind, is going to be a leader in HVAC industry through its total solution capacity differentiated by the development of new environmental-friendly technology and customer-oriented mindset. * website: www.ishinsung.com

- Main Product

Related Products

Thermal Bench

_2.jpg)

Ice Smile Korea Ice Maker Machine Cube Maker(IS-110AP/110WP)

SCREW WATER CHILLER

Absorption Chiller

Platelet Agitator Plasma thawer

South Korea

South Korea