PDS panel tank

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- Seo Heung

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Machinery & Parts , Water Treatment , Water Dispensers & Purifiers

Seo Heung Industrial Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | PDS panel tank | Certification | - |

|---|---|---|---|

| Category |

Machinery & Parts

Water Treatment Water Dispensers & Purifiers |

Ingredients | - |

| Keyword | drinking clean water tank , eco-friendly tank , sectional tank , stainless steel water tank | Unit Size | - |

| Brand name | Seo Heung | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

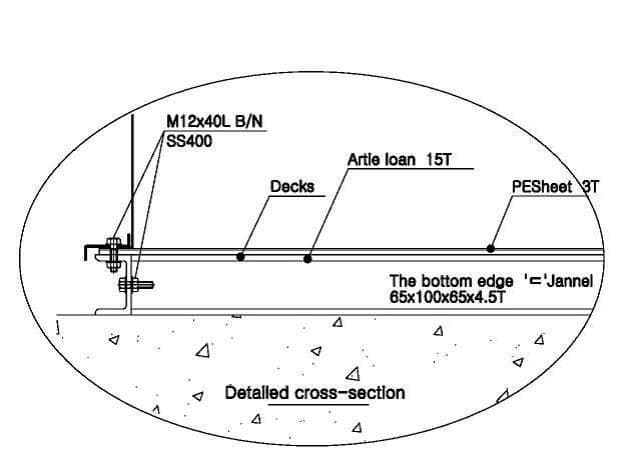

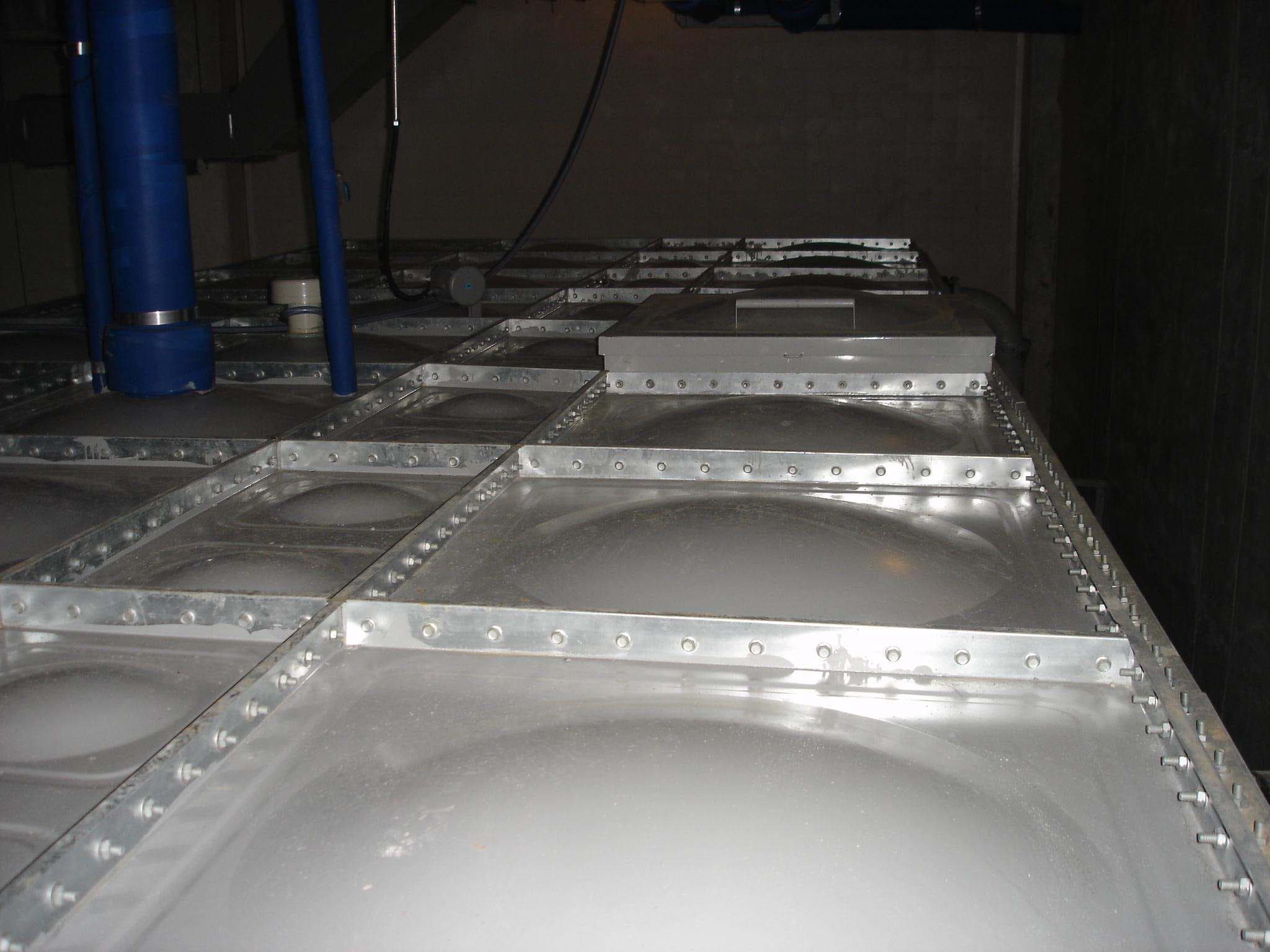

PDS panel tank is assembled by steel plate molded like a ball, sealing tape, metalic structure and bolts.

The advantages of PDS panel water tank.

- It is hygienic.

- It is safe and sturdy.

- It is easy to assemble, move and install.

- It is long-lasting and easy to maintain.

- Space can be used for various purposes.

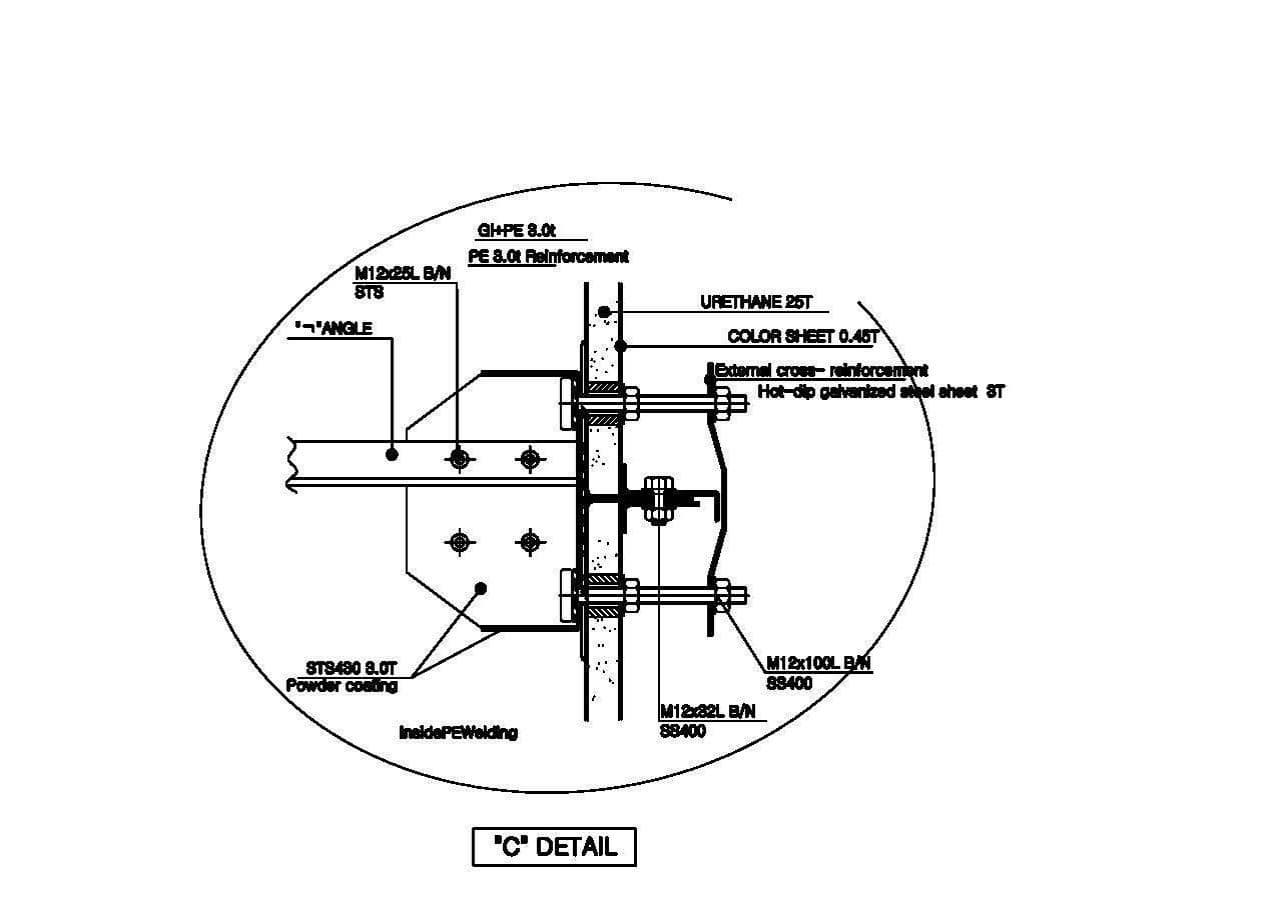

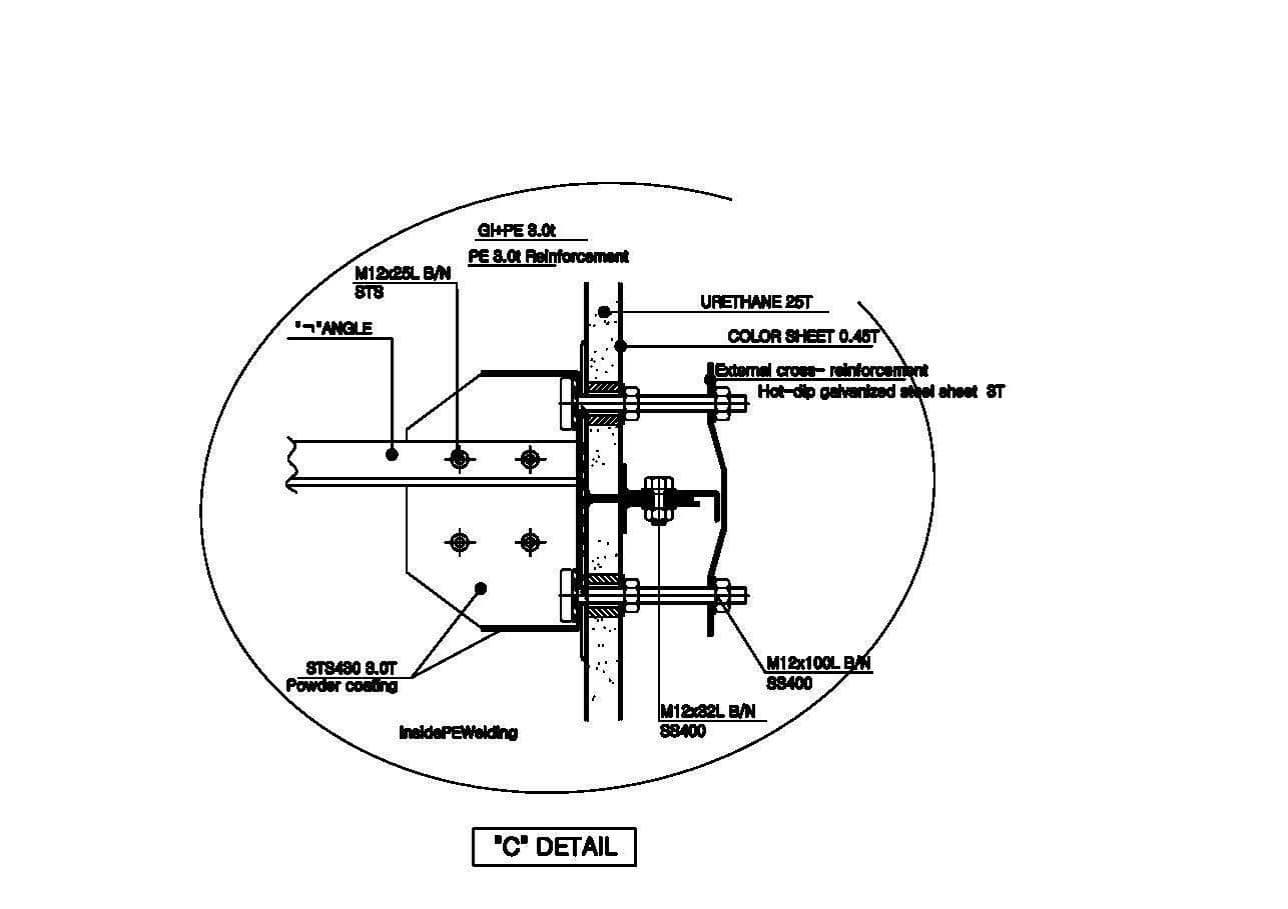

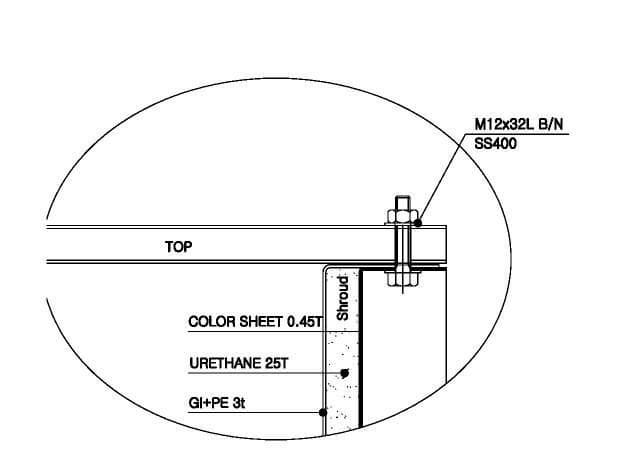

Material: (heat and pressure-applied melting zinc panel on LDPE sheet, molded urethane board (25t) and a color steel plate 0.4t)

- Galvanized steel plate is produced with a panel machined like a ball, and upon the customer's requirements, it is made with a thickness of 1.5mm ~ 5mm.

- Internal reinforcement materials use the method to assemble by tightening nuts and bolts of the angle made of STS304.

- Sealing tape: non-toxic pvc form tapes are used in between all joints.

- Cover of insulation materials: the cover of the tank finishes 0.4mm color steel plate and the insulation is made only at the request of the customer.

- Ladder: the ladder inside and outside shall use the material of sts 304.

- Water gauges consist of a transparent hose and a guard.

- Internal partition: depending on the purpose of use of water, a partition can be installed inside and it can be used by being divided into two, three and four.

|

Material

|

Panel Size

|

Panel Shape

|

Thickness

|

Remark

|

|

PE+Hot dip Galvanized steel

|

1m x 1m

1m x 0.5m 0.5m x 0.5m |

Ball shape

|

1mm∼5mm

|

depending by

height of tank |

|

PE+Stainless steel 430

|

1m x 1m

1m x 0.5m 0.5m x 0.5m |

Ball shape

|

1mm∼5mm

|

depending by

height of tank |

|

PE+Stainless steel 304

|

1m x 1m

1m x 0.5m 0.5m x 0.5m |

Ball shape

|

1mm∼5mm

|

depending by

height of tank |

PDS panel tank

Seo Heung Industry Co., Ltd has manufactured and developed a tank for drinking water and installed STS WATER TANK, PDF TANK, SMC TANK and etc. from the beginning, and has supplied a water tank in eco-friendly and sanitary material in order to consistently keep clean drinking water for about 20 years, and through the efforts of our research team, much cleaner and stronger PDS drinking water tank has been spread. What is PDS Panel?

"PDS" Panel is the steel plate to be compressed and molded by the material of Low Density PolyEthyelene sheet and hot dip galvanized steel and then pressed. This PANEL is assembled and used for the purpose of the water tank.

Characteristic OF PDS panel tank

As LDPE is a material that is harmless to human body, the drinking water is stored in a sanitary manner, and unlike GRP(smc) tank, the bottom panel of "PDS-PANEL" is assembled in a "FLAT" state to enable debris and sludge easy to move when a water tank is cleaned, and its features and benefits are that"DRAIN PANEL" is equipped to be completely drained.

The side panel uses the bracket to unite 4 pieces and it is the way of making the long bolts stick out from the inside to the outside to secure the nuts from the outside.

Internal bracket is made of the STS304 material to increase the strength of steel under the water pressure.

All internal supports should be reinforced with the angle of the STS304 material and the angle should be coated to prevent rust, and the area where the angles of the internal support are crossed should be secured with the STS bolts.

The installation of a partition (2.3.4) is also available so that the water can be used differently depending on the application. Also, put a 25t urethane board on the outside to prevent condensation and freezing and finish the exterior on it with 0.4mm color steel plate.

After using PDS PANEL tank, you can disassemble, clean and move it to the other place and reuse it. PDS is only a water tank with a large capacity in the world which can be assembled without electrical welding by metallic materials, and we are trying to continue the evolution of a water tank and will increase a self-esteem as a global company for a water tank.

PDS PANEL tanks can be used in different areas for many purposes.

Specification of products

1. General Information

1-1 Application Scope

This specification is applied to factory processing, on-site assembly, construction and a comprehensive inspection, in accordance with the installation of PDS-GI (galvanized steel) PANEL.

1-2 Application Standards

- Industrial Safety and Health Law

- Water Supply and Waterworks Installation Act

- Decree of Water Supply and Waterworks Installation Act

- Water tank installation standards

- Rules regarding cleaning and sanitation of the water facility

- New Technology (No. 0488) of Knowledge Economy Ministry

- Excellent product (No. 2010183) of Public Procurement Service

1-3 General Conditions

- All components are designed and produced to suit operational conditions, as well as all the conditions that may caused during handling, storage, transportation and installation.

- PDS water tank should be designed and produced to work easily during operation and maintenance.

- Each of the major components is designed and produced to be compatible as much as possible..

- PDS water tank and its accompanying materials shall be produced based on the regulations and shall not be interfered in use.

2. Designs and Drawings

- All tanks are designed in accordance with data sheet or design sheet received from a purchaser.

- The designers as designated shall prepare drawings and documents designed to meet the applicable regulations or client's specifications.

- All data and detailed instructions required to design, manufacture and purchase shall be indicated in the production drawings, and the necessary things for the production such as drawing number, material specifications, on-site assembly, factory processing, etc. shall be indicated as well.

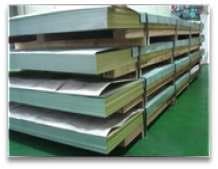

PDS PANEL Processing at the factory

|

|

|

|

1) Galvanized steel sheet

|

2) PE FILM Welding

|

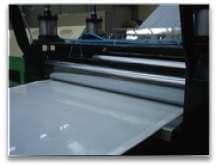

3) PE SHEET extrusion molding

|

|

|

|

|

4) Steel plate processing for PDS PANEL

|

5) Cutting for PDS PANEL

|

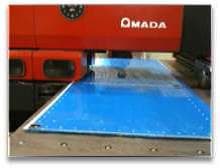

6) NCT Punching and Cutting

|

|

|

|

|

7) BALL SHAPE

|

8) Bending according to PDS PANEL Standard

|

9) Completion of PDS PANEL

|

3. Factory Processing

3-1 Classification of Processing

- PANEL PRESS (BOLT HOLES) PROCESSING (BOTTOM PANEL / SIDE PANEL / ROOF PANEL)

- Extrusion moulding of Polyethylene (PE)

- (Panel of galvanized steel sheet + PE adhesive film + PE 3T integrated processing) (New technology No. 0488)

- BALL SHAPE (SIDE BENDING) processing of panel

- Production of manhole and assembly part, mounting of drain panel and various nozzles

3-2 PANEL PRESSING

The steel plate shall use the one cut in the forward direction at the cutting operation, and shall be used enough to withstand the stress of the water pressure.

3-3 Polyethylene-extruded moulding (New Technology No. 0488)

Polyethylene (PE resin) materials will be injected into the extrusion mold and then galvanized steel and PE sheet will be excluded using double-sided adhesive film in PE at high temperature and low pressure. (There should be no scratches on the surface during extrusion moulding).

3-4 BALL SHAPE Processing (SIDE BENDING)

Bending SIZE (R to be considered) by thickness shall be aligned to match assembly line between panels at the time of on-site assembly, and during the BALL-SHAPE (BENDING) work, it shall not be hit with a hammer or something.

3-5 Production of MANHOLE and ACCY

Shall be produced according to approved drawings and shall be required to receive a supervisor's approval before installation. DRAIN PANEL shall be mounted at a factory after a purchaser's approval. (NOZZLE shall be mounted at a site after a purchaser's approval.)

4. Components and Materials

All panels and internal components shall be finished with materials harmless to the human body for storing the drinking water, and the fence surface shall be done with PE material which is excellent in corrosion resistance and chemical resistance.

4-1 PANEL

- Material

The outer side of the tank is made of GI steel and inner side is made of PE to be integrated.

The cubicle in the middle is made of STS430 steel. (New Technology No. 0488) - The specification of the unit PANEL

The PANEL shall be processed in accordance with the basic specifications, (1000mm × 1000mm), (1000mm × 500mm), (500mm × 500mm), and shall be configured for compatibility based on the size of a tank. - As water pressure is different depending on the height, capacity and applying area of the tank, the panel thickness of galvanized steel sheet by location shall be applied differently depending on the structural calculation.

- DRAIN PANEL: At the time of cleaning, it should have a structure to discharge the water on the ground, facilitate installation of the drain pipe, and there shall be no problem in its strength.

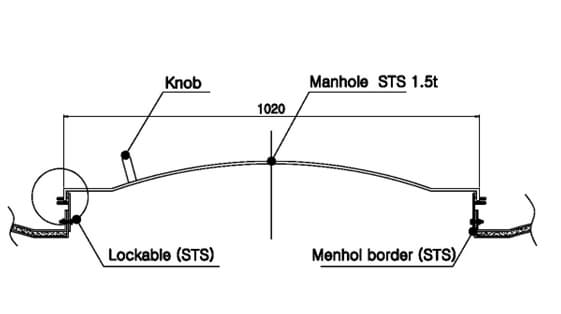

- MANHOLE: It shall be STS 1.5mm which to be installed in the position of the top of the tank and shall be designed to be easy to check out, enter and clean the inside, and shall be powder-coated and locking system shall be installed to prevent debris and pests from entering the tank. (Diameter shall be 950 ㎜ or more)

4-2 Stiffeners and Accessories

- Base frame: As floor PANEL itself has a sufficient rigidity and assembling properties, the basic frame shall be manufactured to "ㄷ" and "ㄱ"-shaped cross-sectional prefabricated type, but shall secure corrosion resistance by the characters made, but after the completion of welding in a factory, molten

zinc plating for corrosion resistance shall be secured. - Internal stiffeners: as a reinforcement to combine powder coating or PE cover after produced with STS304 (KS D 3698), it minimizes deformation of the container side (deformed less than 1% of tank height), and shall be a structure to improve the safety and life of the tank.

- Vertical reinforcement: ‘ㄴ’-Angle 40 × 40 × 3.0mm

- Horizontal Reinforcement: ‘ㄴ’-Angle 40 × 40 × 3.0mm ~ 4.0mm

It shall be applied according to the height of the tank. - External stiffeners: when panels are combined, SS400 (KSD 3503) 3.0t steel shall be processed to secure corrosion hot-dip galvanized resistance in order to secure the rigidity of the Flange face.

- FLANGE reinforcement bar: there are flat bar, 'L' bar, 'Z' bar and depending on the applying height, it can be applied differently. - Internal ladder: as STS structural steel tubes (host tubes: ∅31.8mm, step tubes: ∅25.4mm) material, it shall be produced and powder-coated at 400mm (W) x 350mm (H) intervals.

- External ladder: as STS structural steel tubes (host: ∅ 31.8mm, step tubes: ∅ 25.4mm) material, it shall be made at 400mm (W) x 350mm (H).

- Vent: as a PVC material, it shall be a structure to block the intake of insects and foreign matters.

- Bolts and nuts: the dimensions of the bolts shall conform to KS standards and diameter shall be more than 10mm.

- Bolts for internal use: over STS shall be applied.

- Bolts for external use: dachro-plating shall be applied.

- Bolts for internal and external connection: the bolts used for internal bracket assembly shall be coated with PE enough to have watertight. - Sealing material: it shall be harmless to humans, and as PVC type of a material to withstand changes in temperature and have good resilience for watertight and excellent durability, TAPE shape shall be handled easily.

- NOZZLE: as PE or STS materials, NIPPLE shall use brass.

- Insulating materials (optional): Polyurethane molding board (25t) will be attached to the outside of the galvanized steel and finished with color steel plate (0.4mm).

Instructions for PDS Panel Assembly

1) Unloading and loading (loading separately according to the work process)

|

Assembly Views in Part

|

|

|

|

|

Transportation of Materials

|

Loading of PDS Panel

|

|

Components

|

Check materails according to the list

|

|

Detailed

description of Assembly |

Prepare the next process when unloading a product in the car.

|

|

Instructions

|

|

2) Assembly of Bottom Plate

|

Assembly Views in Part

|

|

|

|

|

Assembly of bottom plate

|

Assembly cross-sectional view of bottom plate

|

|

Components

|

Bottom plate panel, external assembly bolts, bottom frame, corner frame, liner

|

|

Detailed

description of Assembly |

|

|

Instructions

|

|

3) PE Sheet / Heat and Pressure to Impress

|

Assembly Views in Part

|

|

|

|

|

Cutting Work of PE Sheet

|

PE Sheet Thermosetting

|

|

Components

|

PE Sheet

|

|

Detailed

description of Assembly |

|

|

Instructions

|

|

4) Installation of Drain Panel & Drain Pipe

|

Assembly Views in Part

|

|

|

|

|

Installation of Internal Drain panel

|

Installation of External Drain pipe

|

|

Components

|

Internal and external drain, external bolts, drain bolt (Square-head PE

coating) |

|

Detailed

description of Assembly |

|

|

Instructions

|

|

5) Assembly of Side Panel

|

Assembly Views in Part

|

|

|

|

|

Assembly of Side Panel

|

Cross-Sectional View of Side Panel Assembly

|

|

Components

|

Side panel, external assembly bolts, flange reinforcement bar (YKFB-ZZ, ZL for side panels ), sealing tape

|

|

Detailed

description of Assembly |

|

|

Instructions

|

|

6) Installation of Internal & External Nozzle

|

Assembly Views in Part

|

|

|

|

|

Attachment of PE Nozzle (Inside)

|

External view after Nozzle was attached

|

|

Components

|

Internal and external nozzles (Fire-extinguishing LINE, OUT LINE), External Bolt

|

|

Detailed

description of Assembly |

As PE pipe is welded by referencing the drawings of the nozzle, be |

|

Instructions

|

|

7) Assembly of Internal Bracket & External Bracket

|

Assembly Views in Part

|

|

|

|

|

Assembly View on Internal Bracket

|

Internal bracket, bolts for internal and external brackets (Square-head PE coating), Packing

|

|

Components

|

Internal and external nozzles (Fire-extinguishing LINE, OUT LINE), External Bolt

|

|

Detailed

description of Assembly |

|

|

Instructions

|

|

8) Assembly of Internal Stiffeners

|

Assembly Views in Part

|

|

|

|

|

Internal Reinforcement Assembly

|

Cross-sectional View of Internal Reinforcement Assembly

|

|

Components

|

Internal Stay, Ceiling Support, Cross Bolts

|

|

Detailed

description of Assembly |

|

|

Instructions

|

|

9) Installation of Internal & External Ladder

|

Assembly Views in Part

|

|

|

|

|

Installation of an Internal Ladder

|

Installation of an External Ladder

|

|

Components

|

Internal and external ladders, internal and external bolts

|

|

Detailed

description of Assembly |

As a ladder has a hole in the upper side, manhole bands can be assembled.

|

|

Instructions

|

|

10) Assembly of Roof Panel

|

Assembly Views in Part

|

|

|

|

|

Assembly of ROOF PANEL

|

Roof panel, flange reinforcement bar for top plate, external bolts, air vents, roof plate flange, corner flange, support bolts

|

|

Components

|

Internal and external ladders, internal and external bolts

|

|

Detailed

description of Assembly |

|

|

Instructions

|

|

11) Assembly of Manhole

|

Assembly Views in Part

|

|

|

|

|

View of Manhole Assembly

|

Cross-sectional View of Manhole Assembly

|

|

Components

|

Manhole, bolts for manhole, bands for manhole, manhole cove

|

|

Detailed

description of Assembly |

|

|

Instructions

|

|

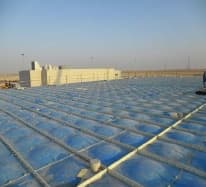

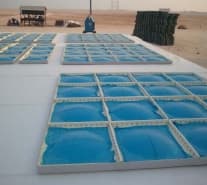

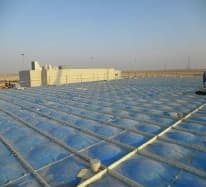

Assembly Views in the UAE site: 4,000tons (W 25m x L 40m x H 4m) 2units

|

|

|

1) Before assembly of bottom plate on the base pad

|

2) Assembly of drain panel and bottom plate

|

|

|

|

3) PE sheet attached on the bottom plate

|

4) PE sheet attached on the bottom plate

|

|

|

|

5) Putting up SIDE PANEL

|

6) SIDE PANEL and Internal Partiti

|

|

|

|

7) Internal Stiffener Assembly

|

8) Assembly of Internal Stiffener and Parti

|

|

|

|

9) Assembly of top plate

|

10) Completion of water tank assembly

(W25m x L40m x H4m) |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Byung Ha Yoo

- Address

- #204, 11, Achasan-ro 11-gil, Seongdong-gu, Seoul

- Product Category

- Steel Sheets,Water Treatment

- No. of Total Employees

- 1-50

- Company introduction

-

SeoHeung Industry Co., Ltd is a specialized company that has been making only an environmentally friendly and hygienic drinking water tank in stainless steel for more than 20 years and achieved the recognition after installing the products on the construction sites of Hyundai Engineering & Construction Co., Ltd. and Daelim Industrial Co., Ltd. which are global enterprises as well as government agencies.

We have developed a new product which is easy to manage, inexpensive and improve quality, increase strength and is easy to move and install, based on our experience and knowledge in the past. The most important parts of the water tank are the panel and the internal reinforcement materials, and the strong point can be structural robustness.

Hygienic and safe water tank are called PDS PANEL TANK.

We will produce a product with a system to completely fulfill the needs of various customers, continue research and development and will try our best to further the better health of the global people. (KOICA registrar) Children were born to be loved. Unfortunately, in many countries of the world, where there is no clean water, children and women have suffered from various diseases and pains, and even the babies have died. The reality that the children do not go to school to get water is so unfortunate, so if all people of the world are trying to work together and solve these issues, the world will be more beautiful.

If you need the data on the sectional water tank and send us an email, we will give you an answer in good faith (size, material, intended use, etc)

If you are also interested in production, sale or installation work of the sectional water tank, please send us an email.

- Main Product

Related Products

Automatic Rebar Bending Line

KBC Bearing

AIRLESS PUMP- YL 731

_2.jpg)

Turbowin Turbo Blower (WL Series)

AIS3000 HD