SPALATO BRICK

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- Valpietra

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Artificial Stone

PGL-Factory srl

- Country / Year Established

-

Italy

/

Italy

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | SPALATO BRICK | Certification | - |

|---|---|---|---|

| Category | Artificial Stone | Ingredients | - |

| Keyword | artificial stone panels , artificial stone slabs , cladding stones | Unit Size | - |

| Brand name | Valpietra | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

SPALATO BRICK

As regular wall, reproduces the characteristic split stone "spaccatello" , is laid one on top of the other with no grout.

Features:- PANEL DIMENSION: 28 x 60 cm;

- THICKNESS: 0.5 ÷ 2 cm;

- WEIGHT/sqm: 29 kg/sqm;

- WEIGHT/piece: 4 kg/pc;

- BOX: 5 pc - 0.67 sqm - 20 kg;

- PALLET: 24 boxes - 16,08 sqm - 510 kg;

- GLUE CONSUMPTION: 3.5 kg/sqm.

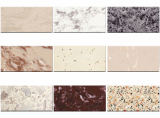

Codes - Colours:

- 9502.001 - Botticino

- 9502.002 - White

- 9502.003 - Grey

- 9502.004 - Slate

Preparation for Laying:

The VALPIETRA® panels can be laid directly on bare walls, plastered and/or painted surfaces and on any support in the form of chipboard, adhering to the following warnings:

In general:

- the laying surface must be compact and free of dust and dirt. Any traces of greases, waxes, oils, enamels, varnishes, etc., must be removed;

- concrete bases must be dry to avoid loss of adhesion;

- any rising damp should be dealt with and solved before laying;

- for installation on walls more than 3 meters in height a wire mesh must be used as a support;

- a double layer of glue is needed (one the wall and one on the panel) applied with a toothed spatula.

In particular:

- bare walls: if the surface of the walls are not flush and compact then they have to be smoothed

- plastered and/or painted surfaces: provide a stitching of the laying surface (in the case of not using the AV9 glue, a primer must be used)

- supports in chipboard, MDF or plasterboard must be anchored to the underlying wall, to support the total weight of the panels (in the case of not using the glue AV9, you must use a primer.

Operating Limits:

- do not use in areas that are completely immersed in water;

- do not lay by direct heat or in contact with metal components that reach high temperatures;

- maintain a distance of at least 30 cm in the case of laying on walls behind pellet wood burners;

- don’t lay on walls behind directly on the heat source;

Certifications:

The product line VALPIETRA®, composed exclusively of recycled marble and acrylic binder presents aesthetic and mechanical characteristics equivalent to those of natural marble. All of the VALPIETRA® panels are thus suitable for the following standards:

- Water absorption - UNI EN 14617-1

- Flexural - UNI EN 14617-2

- Resistance to freezing and thawing - UNI EN 14617-5

- Resistance to impact - UNI EN 14617-9

- Resistance to hydrochloric acid - UNI EN 14617-10

- Resistance to sodium hydroxide - UNI EN 14617-10

- Compressive strength - UNI EN 14617-15

- Resistance to fire - UNI 8457/9174 / UNI EN 13501-1:2005

- Toxicity of gases - ATS 1000.001

- Accelerated aging - UNI EN 4892-2

- Thermal transmittance - UNI EN 12664:2002

Guarantee:

- The artificial stone veneer is guaranteed for ten years as normally required for building products.

- The warranty does not cover labor costs for the replacement of defective parts.

- Any defective parts must be discarded before use.

- The warranty does not cover damage caused by contact with aggressive chemicals.

- The warranty does not cover damage caused by the movement or settling of the wall.

- The warranty does not cover damage caused by oxidation or dirt.

Take Care:

Since this is a handmade product with a mix of stone there can be fluctuations in tone between the various production batches.

Do not sand, do not clean with high pressure water, do not use abrasive tools or cloths.

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Paolo Scian

- Address

- Via Maestri del Lavoro 10 - 33080 Porcia - Pordenone - Italy

- Product Category

- Artificial Stone

- No. of Total Employees

- 1-50

- Company introduction

-

The market of artificial stone actually proposes the reconstruction of the shapes and the appearance of natural stone, utilising as a prime material inerts of different origins and a variety of binders. These, after the various mixing stages, get poured into moulds, and the mix goes through a series of consolidation and drying processes. From the prime materials to the acrylic resin, from the moulds to the boxes, only Italian components and materials are used on the VALPIETRA® production line. The entire production process is done on site in our factory, including the natural drying procedure and the final packaging. Even the silicone moulds needed for the casting of the cold mixture are designed and produced in our factory. The manufacture of our products, has been kept at a HANDMADE level, reflecting our philosophy of environmental sustainability pursued by our company. In particular: - only the scraps from marble quarries along the Alps are recycled as raw material; - the marble scraps are first ground and then mixed with an acrylic resin into an aqueous solution, it is completely non-toxic and eco-friendly; - the prepared mixture is then poured cold into silicone moulds, made directly from the CAST of some varieties of natural rocks, thus able to give the finished product a totally realistic and natural appearance, to the eye and to the touch; - a step of natural drying (maturation) follows without any application of external heat and a final treatment anti -stain protective surface. The ‘manic’ direct care and attention to details, which encompasses the entire production process from the conception of the molds to the last checks of a single panel prior to packaging, guarantees the quality of a new product. This is particularly interesting for a market, which is increasingly looking for modular, easy to apply, attractive solutions. Not even the size and weight of the panels VALPIETRA, are left to chance: The lateral fixed joints in each model with their various finishes, are designed to make it as quick and easy as possible to lay without the need to grout the joints afterwards. The reduced weight, also allows the laying of the components, even on complex surfaces, by a single contractor, without requiring any specific attachment system, only classic adhesive for tiles. A do-it-yourself predisposition is enough to lay our panels with ease and rapidity, to ensure a real saving of labour costs. In a market where competitors use cement and/or epoxy based resins, which have a severe environmental impact. It is to be emphasised that our company, with our VALPIETRA® line, is unique with a low environmental impact; from the cold technology production of the cladding panels and the use and development of high performance water-based acrylic resins. The advantage of this production process is that each manufacturing phase, does not require the use of energy therefore it could be classified as a non energetic consumption process. The environmental impact is further significantly reduced with using natural raw materials and non-toxic water soluble binders. This makes an eventual, disposal process equivalent the same as that of real stone, not requiring any special disposal treatments.

- Factory Information

-

PGL-Factory srl

- Main Product

Related Products

Vietnam Quartz Countertops

Artificial Marble, Engineered Quartz, China

Multi-Colors Nano Crystallized Glass Big Slabs

Pietra Grey marble, Block, slab and tile

WT2 Stair Tread