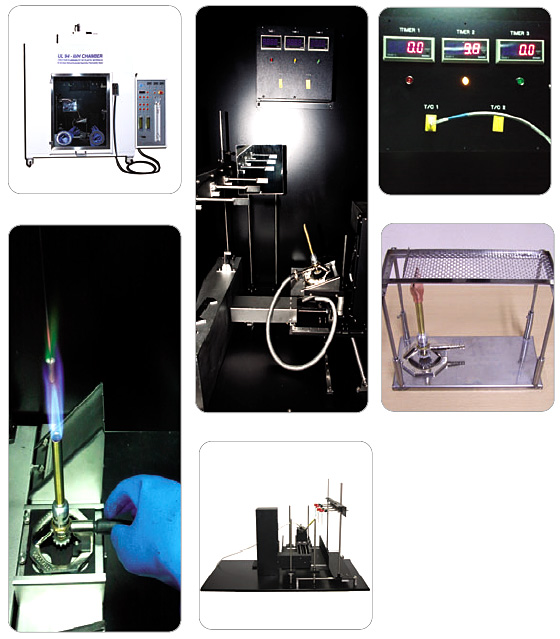

UL 94 - AVH Chamber

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Testing Equipment

Festec International Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | UL 94 - AVH Chamber | Certification | - |

|---|---|---|---|

| Category | Testing Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

UL-94 AVH Chamber, UL-511, UL-P11, ASTM D 5048, ASTM D 3801, ASTM D 4804, ASTM D 4986, ISO 10351,ISO 1210, ISO 9772,3, IEC 707

Introduction

UL 94 measures the combustion properties (after flame, after glow) by burner (H-5025 UL tirrill burner) when test sample combusts in chamber's internal volume of 0.864m3 and is installed internal light to observe the specimen's properties and has ventilating opening with emission fan to remove the combustion gas.

FESTEC's UL 94-AVH has auto specimen moving system for protecting user from hazardous gas and auto burner moving system for meeting the whole test standards. This auto burner moving system has a goniometer, so it can change the angle of flame to the specimen (0°, 20°, 30°, 45°, 90°).

Control box and remote controller help user to handle this equipment or check after flame time and after glow time during testing and are able to adjust the angle.

Standard

- Horizontal Burning Test : UL 94HB (ASTM D 5048 or ISO 10351).

- Vertical Burning Test : UL 94 V-0, V-1, or V-2 (ASTM D 3801, IEC 707, or ISO 1210).

- 500w (125mm) Vertical Burning Test : 5VA or 5VB (ASTM D 4804 or ISO 9773).

- Thin Material Vertical Burning Test : VTM-0, VTM-1, or VTM-2 (ASTM D 4804 or ISO 9773)

- Horizontal Burning Foamed Material Test : HBF, HF-1, or HF-2 (ASTM D 4986 or ISO/ DIS 9772.3)

- KS M 3015 : Testing method for thermosetting plastics

- KS M 3305 : Liquid unsaturated polyester resins for fiber reinforced plastics

- KS M 3809 : Thermal insulation material made of rigid urethane foam

- KS M ISO 9772 : Cellular plastics-Determination of horizontal burning characteristics of small specimens subjected to a small flame

Features

- Auto specimen moving system (The Switch 'MOVE 1' in the control box enables random control and operation by user) facilitating automatic movement and removal of sample to the ignition source

- Auto Burner Moving System (The Switch and Remote Controller switch 'MOVE 2 & 3' in the control box enables random control and operation by user) enabling adjustment of different ignition time and burner angles by each standards

- Cable Handy Remote Controller facilitating operation of Timer 1, 2 and 3 in the UL 94-AVH Control Box and Auto Burner Moving System

- Double-coated chamber equipped with exhaust fan to readily discharge combustion gas and internal lighting, whose internal volume is 0.864m3

- Burner Calibration Kit to measure 20mm of flame and 125mm of flame under ASTM D 5207 (Copper slug thermocouple and digital thermal indicator for 20mm of flame and 125mm of flame)

- Thermal Indicator and Thermocouple Connector in the control box facilitating calibration of flame calories by the Copper Slug(ASTM D 5207)

- Burner complying with ASTM D 5025 equipped with the precision control system including goniometer facilitating adjustment of burner angles (0°, 20°, 30°, 45°, 90°) frame and gas flow meter in addition to manometer

- Control Box adjustable at intervals of 30 degrees facilitating time adjustment and operation of the timer by user' slocation

- Sliding Door made of reinforced glass to observe sample and prevent user from inhaling noxious gases during test

- 2 access ports on the front of the chamber to protect user from inhaling noxious gases, adjust the burner and devices in the chamber and move and fix samples

- Clamp facilitating separation and attachment(easy to removable) of test sample

- Units and accessories to change flame shape and burner angle in diverse test methods by standards (For example, accessories capable of HBF, HF and ISO 9772 tests)

- 3 digital timers to measure simultaneously the time of after flame, after glow and after light the touch screen panel PC

- Window 2 Step Locking System easy to handle the specimen

- Three select options : Manual, Semi-Auto, Full Auto Type

Specification

| Model | FT-UL-511, FT-UL-P11 |

| Size | 1,600(W) x 650(D) x 1,620(H)mm |

| Size(Table) | 2,500(W) x 800(D) x 600(H)mm |

| Power | AC 220V, 50/60Hz, 10A |

| Weight | 100kg |

| Manual | Supply |

| Exhaust | 50L/s |

| Utilities | Compressed Air, Methane, , Dust Collector |

Test Result

- After flame : Flame continued even after a firing source disappears

- After flame Time : Time taken for after flame continued under specified conditions (unit: second)

- After glow : Glowing combustion continued even after an ignition source and flame disappear

- After glow Time : Time taken for after glow continued under specified conditions (unit: second)

- Damaged length (Damaged length of test sample, unit: mm)

- Ignited the cotton indicator by drip flaming(Ignition of cotton by a dropped flame piece) After glow

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Festec International Co., Ltd.

- Address

- #801, 814, Byuksan Digital Valley 5, 244, Beotkkot-ro, Geumcheon-gu, Seoul, Korea

- Product Category

- Testing Equipment

- No. of Total Employees

- 51-100

- Company introduction

-

The corporate name FESTEC, as an abbreviation of Fire Engineering & Science Technology, reflects our intention to be a leader in the field of fire engineering and science by devoting ourselves to accumulating fire-related technologies to prevent human beings from economic loss and bodily injury by a fire.

Further, FESTEC will expand the business into research of advanced fire technology, certification service, and development of materials and test methods.

Bodily injury and economic loss from fire are being more emphasized in advanced countries. Therefore flame-retardancy and fire-resisting products shall be subject to conformity test to relevant standards, for example, interior finish materials of railway vehicles and buildings, fire-resistant cable etc. are included.

Therefore, conformity to standards shall be rated with our test equipment, although our fire test equipment market depends upon foreign test equipment, at present. Like this, FESTEC INTERNATIONAL's growth has a thread of connection with national policy.

For any inquiries about our products, we will sincerely respond to you all the time.

- Main Product

Related Products

_2.jpg)

Cable and Wire harness tester (MHT-610 / 705)

INSULATION TESTER TKM-910, TKM-920

Hi-Fix Board

_2.jpg)

Common Rail Injector Test Bench (V310EX)

Muffle Furnace