Robot Dress Pack System

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Kyung In MJ System Co., Ltd.

- Verified Certificate

-

17

| Product name | Robot Dress Pack System | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

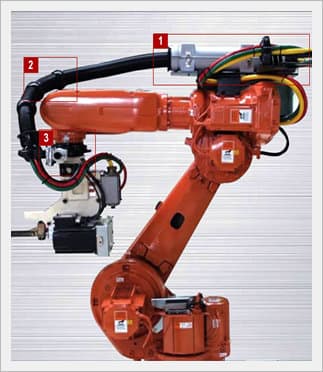

Robot Dress Pack System

U-Type Features

1. Maximum spring contraction of 900mm.

1. Cables always remain in an optimum position even when the robot is in irregular position.

1. The main base is adaptable for various types of utilities.

1. Cable termination can be made with connector or junction box.

1. An optimum position is obtained with spring return.

2. Flexible Tube is directly connected to the end effecter (R axis) without any support so that robot can be operated in a limited space and any interference will be minimized.

3. Easy to install and move in directional change via use of clamping type attached to end effect(R-Axis) of robot.

3. Easy to move in different directions. Through adjustable mechanism at angle, any direct contact is eliminated in installation so that robot teaching can be easily implemented.

3. Prevents the hose and cables inside dressing pack from twisting while turning on the R-axis.

|

Full Length

|

6m

|

|

|

Flexible Tube Length

|

2m

|

|

|

Flexible Tube Spec.

|

R90G-70XY/NP.30

|

Components & Spec.

Remark Length of cables and Urethane hoses can be altered according to type of robot and application.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Lee, Jin-seob

- Address

- #3Ba-306, Shihwa Industrial Zone, Jeongwang-dong, Siheung-siGyeonggi-do,

- Product Category

- Welding Equipment

- No. of Total Employees

- 1-50

- Company introduction

-

Since it foundation 1998, We, Kyung In MJ System company objective is do our best to customer's growth, We supply all of spare parts using for welding industry field, Also, We have good organization, Our continuous Quality Management, Cost Reduction. That is why giving our customer more competitive price.

We at Kyung In MJ System, concentrate our all of effort supplying using for Resistance Welding parts Kickless Cable, Jumper Cable & Special Alloy (Chrome Copper, Beryllium Copper, Copper Tungsten, Molybdenum, Tungsten) & Electrode, Shank, Holder, Welding Gun and Including Electric Control Device(SCR, Diode Stack) & Spare parts for ARC welding M/C(CO2, Tig, Plasma, Gouging).

We concentrate our all of effort piece by piece.

Any of inquiry using for Welding Machine & Spare parts in Welding Industrial, We promise that all of effort to satisfy with our customer demand.

- Main Markets

-

China

China

Japan

Japan

Russia

Russia

U.S.A

U.S.A

Ukraine

Ukraine

- Main Product

South Korea

South Korea