Wire Rope Clip

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery Parts

Sunjin Power Tecg Co., Ltd.

- Membership

- PRO

- Recent Visit

- Jan 15, 2025

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | Wire Rope Clip | Certification | - |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

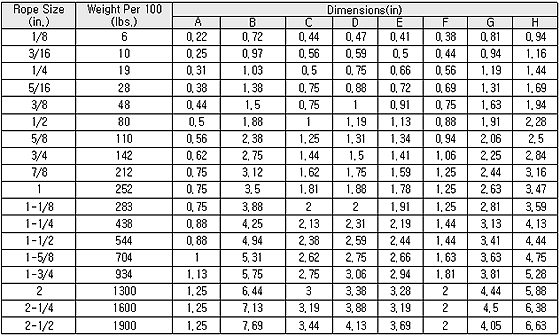

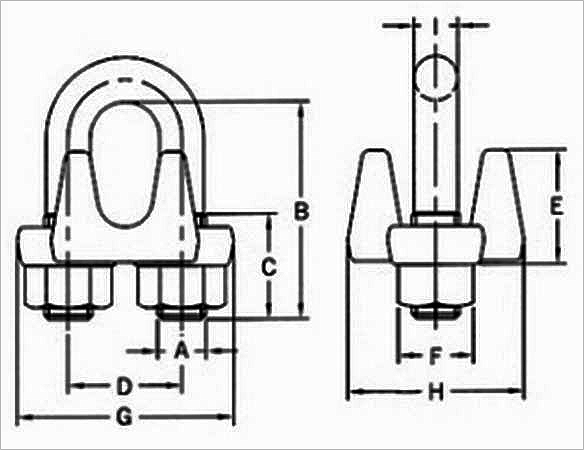

Products Drawing

Specification (Click to the large image)

- Forged Carbon steel

- Normalizing

- Electric plated or Hot-Dip galvanized.

1. General Theory

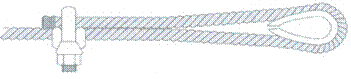

- Wire rope clips are used on wire rope eye-loop connections or complete-loop, end-to-end connections where socketing or splicing is not feasible when a non-permanent or temporary joint is required.

- Match the same size clip to the same size wire rope.

- Don't use with plastic coated wire rope.

2. Before Using

- Must be take a provide personal protection equipment. (Such as footwear, gloves, Crash helmet, etc.)

- Working place always shall be the lighting.

- Shall be work, before remove dangerous article in the surroundings.

3. Using

- Never make a wrong application of the rule. (Overloading & Improper use can result in injury.)

- Over the 20kg weight products' using, must be use an appliance tool. (Forklift, crane, hoist, etc.)

- Where apply, must locate outside the danger zones. (A falling load may cause serious injury or death.)

- Never repair, alter, rework, or reshape a shackle by welding, heating, burning, bending or grinding.

- Apply first load to test the assembly. This load should be of equal or greater weight than loads expected in use. Next, check and retighten nuts to recommended torque.

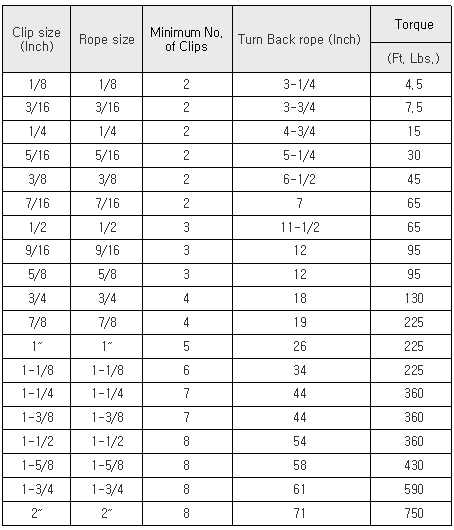

- For application

|

|

| 1. The first clip must be placed one saddle width from the turned back rope tail or dead end of the rope. - Tighten the nuts to the specified torque. (See Figure 1) |

|

| 2. The second wire rope clip must be placed immediately aginst the thimble but nevertheless in such position that correct tightening of the grip does not damage the outer wires of the rope. - Turn on the nuts firmly not yet to the specified torque. (See Figure 2) |

|

| 3. All other grips must be placed between the first and second clips in such way that they are separated by at least one clear clip width from each other. - Apply light tension on the rope and tighted all nuts to the specified torque. (See Figure 3) |

4. Important

- Apply first load to test the assembly. This load should be of equal or greater weight than loads expected in use. Next, Check and retighten nuts to recommended torque.

- In accordance with good rigging and maintenance practices, the wire rope end termination should be inspected periodically for wear, abuse, and general adequacy.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Duk Ho, Sun

- Address

- 10-38, Hangdong-ro 143beon-gil, Bupyeong-gu, Incheon, Korea

- Product Category

- Other Machinery Parts,Steel Structures

- No. of Total Employees

- 1-50

- Company introduction

-

SUNJIN is manufacturing the Rigging Hardwares for shipbuilding, construction, and machinery.

Our porducts are exporting to USA., Cananda, Netherlands, Singapore, Switzerland and most of customers are satisfied with our quality since our products have good tensile force and stability.

We are doing our best in order that customers use our products with an easy mind through strict quality control, reliable price, on-time delivery.

If you have any question about our products or technical matters on the rigging hardwares, please contact our customer center without hesitation.

Thank you.

- Main Product

Related Products

180 degree rotation brushless servo XQ-S5650D

EMI Shielding Metal Spring Gasket

JS-2EJ4

FR Coating

All in one POS SYSTEM