Smart System (Pallet Type)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Cargo & Storage Equipment

Korea Electric & Machinery Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Smart System (Pallet Type) | Certification | - |

|---|---|---|---|

| Category | Cargo & Storage Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

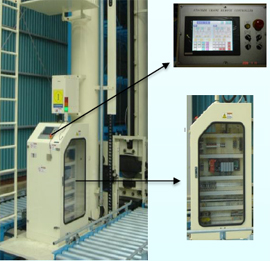

Smart Systems for Pallet Unit type automatic storage system

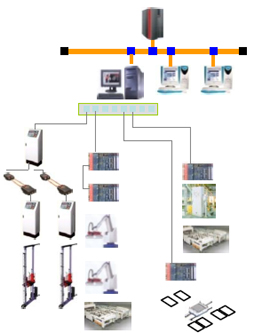

That the mission of the automatic warehouse system achieves spatial effective use and high-efficient storage and retrieval. Smart System of Korean E&M is the automated storage and retrieval warehouse system most suitable for the management of weight items of the Pallet unit. Storage and retrieval by 1 point is done and the big effect is brought by substantial reduction in physical distribution cost and practical use time reduction-ization. The weight items and material safekeeping are more flexible by storage and retrieval and are to connect to softer correspondence and dominance computer, and it's possible to systematize the peripheral device department of a lot of Stacker Cranes and Conveyor.

- The design of high-speed

- Stacker Cranes in the control of light weight and high-speed Driving speed 140m / m to the UP. - High storage efficiency

- Take maximum advantage of the upper space to the ceiling and, stock greatly increase the efficiency fixed RACK compared to about 1 / 3 of the space that you can save. - Reduction of labor in entry and exit of heavy goods

- Crane driving between two Rack, and automatically, because the Shipping & Receiving, Fork lifter looking at, remove, transport operations that are unnecessary. Shipping & Receiving heavyweights, and when working with products and materials can make faster and reduction of labor. - Installation height up to 21m, various models

- Installation height up to 21m, various models - Total System

- When you connect to the top Computer Stacker Crane and Conveyor, such as multiple connections to a variety of peripherals are available.

| Stacker Crane body | Rack body |

| Double Mast to be a high-strength design, Chain Type, Wire Rope Type 2 types standardization | Strength as a supporter of each Pipe OK to 1.5Ton/pallet |

|

|

| Controller | Total logistics System developable |

| PLC universal design, maintenance and operation simple, the ordering of driving the situation on the LCD Panel display for anyone, simply Operation | When you connect to the top Computer, the plurality of peripheral devices, such as Stacker Crane and Conveyor can be maximized by combining the efficiency |

|

|

Specification

| ITEM | K1000-6H | K1000-9H | K1000-12H | K1000-15H | K1000-18H | K1000-21H |

| Rack Height | 6,000mm | 9,000mm | 12,000mm | 15,000mm | 18,000mm | 21,000mm |

| Maximum load | 1,000~1,200kg | |||||

| Loading appearance | W800~1,500 / L800~1,500 / H500~1,500mm | |||||

| Travel speed | Max.80 ~ 140 (Inverter)m/min. | |||||

| Ascent rate | Max.20 ~ 50 (Inverter)m/min. | |||||

| Fork Speed | Max.20 ~ 50 (Inverter)m/min. | |||||

| Fork Type | Single Fork / Twin Fork / Double Reach Fork | |||||

| Controller | PLC ( Programmable Controller ) Korea Electric | |||||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- RYU, SEUNG-HWAN

- Address

- #723, Anyang Mega Valley, 799, Gwanyang-dong, Dongan-gu, Anyang-siGyeonggi-do,

- Product Category

- Other Machinery & Industry Equipment

- Company introduction

-

We are spcialized in Material Handling Autoation System, engineering, designing, manucaturing and installation. All the engineers in our company have a lot of experience in automatic storage system, automatic guided vehicle system, palletize, high-speed sorting system, automatic rifle range, order-made assembly line before they join our company. We put the first priority in out clients needs and we start consulting and engineering after clients' environments. We supply the best fitted system with best fitted material handling equipment and control software and hardware made by our own staffs in our factory. Our work scope cover supplying the system and installation and trial operation and maintenance. We enjoy good reputation in remodeling matrial handling system, increasing the efficeny by 30% over from many clients.

- Main Product

Related Products

Stacking Racks Palletainer

SERO-VMR

medium duty boltless rack steel plate storage shelf rack

Aerial Work Platform - Boom Lift Truck HS300

Precision planetary gearhead