Asphalt Mixing Plant

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Taeshin Corporation

- Verified Certificate

-

17

| Product name | Asphalt Mixing Plant | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Asphalt Mixing Plant

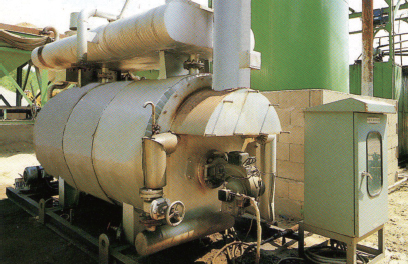

- TSAP series asphalt mixing plant maximizes the thermal efficiency.

- Dryer Wing of conventional Drum Dryer has been improved for high efficiency of dispersion & drying.

- The burner equipped with complete combustion booster dries asphalt efficiently without losing viscosity which leads to 10~20% asphalt saving.

- Aggregates can be evenly coated through efficiently arranged mixing paddles in Bi-axial spiral mixer during asphalt discharge.

- Hot bin is designed to avoid aggregate segregation and maintain even asphalt rate in ASCON.

- Asphalt storage tank prevents asphalt from oxidation with preheating system.

- Whole facilities are equipped with bag-filter dust collecting system which achieves 99.6% of dust collection efficiency.

- Screen unit is installed horizontally so as to prevent aggregate concentration and minimize abrasion of screen.

- Load-cell is adopted for weighing meter.

- Automatic control panel consists of micro computer system & PLC, which enables efficient remote control.

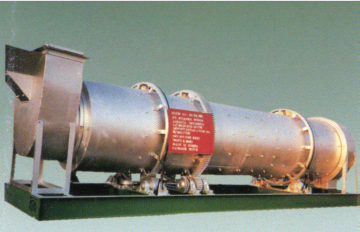

Portable Asphalt Mixing Plant

The new type of dryer wing enable aggregates to be heated evenly and transferred smoothly

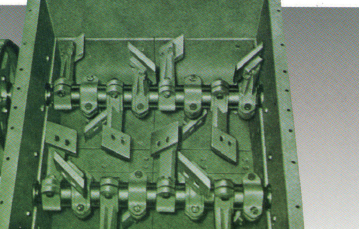

The counter-flow twin-shaft mixer is equipped with wear-resistant liner and adjustable mixing paddle. Paddle tip is easily replaceable. Mixer gate is actuated by heavy duty cylinder for instant discharge.

The hot oil heater heats up the oil with fully automatic burner system.

|

Model

|

Mixer

|

Capacity

|

|

TSAP-08

|

800Kg / batch

|

64t / hr

|

|

TSAP-10

|

1000Kg / batch

|

80t / hr

|

|

TSAP-13

|

1300Kg / batch

|

104t / hr

|

Taeshin's Asphalt Plant Specifications

|

Dscription

|

TASP-800 64 T/Hr

|

TSAP-1000 80T/Hr

|

TSAP-1550 124T/Hr

|

TSAP-2000 160T/Hr

|

TSAP-3000 240T/Hr

|

TSAP-4000 320T/Hr

|

|

|

Cold Bin (m3 x SET)

|

5 x 4

|

6 x 4

|

12 x 4

|

12 x 4

|

12 x 5

|

12 x 5

|

|

|

Belt Conveyor (T/Hr)

|

80

|

100

|

130

|

180

|

250

|

360

|

|

|

Dryer (Ø x mm)

|

1550 x 600

|

1600 x 7000

|

2000 x 7500

|

2250 x 8480

|

2750 x 9000

|

2950 x 10000

|

|

|

Dryer Burner (ℓ/Hr)

|

420

|

560

|

840

|

1120

|

1680

|

2240

|

|

|

Turbo Blower (M/Min x mmAq)

|

Turbo Fan Type

|

||||||

|

110 x 350

|

150 x 350

|

220 x 350

|

300 x 350

|

450 x 350

|

600 x 350

|

||

|

1

|

1

|

1

|

1

|

1

|

1

|

||

|

Dry Cyclone (Ø x mm)

|

1800 x 6220

|

2300×6550

|

2000 x 7800 x 2

|

2000 x 7600 x 2

|

2300 x 7500 x 2

|

2700 x 8000 x 2

|

|

|

Exhaust Fan(M/Min x mmAq)

|

Plant Fan Type

|

||||||

|

470 x 400

|

670 x 400

|

800 x 400

|

1140 x 400

|

1400 x 400

|

1800 x 400

|

||

|

Hot Elevator (T/Hr)

|

80

|

100

|

130

|

180

|

250

|

360

|

|

|

Screen

|

Vibrating Type 4Kinds of Size 3.5 Stages

|

||||||

|

Hot Bin (m3)

|

4.5

|

6

|

16

|

24

|

30

|

40

|

|

|

Aggregate Scale (kg)

|

0.5~800

|

1~1000

|

1~1550

|

4~2000

|

5~3000

|

6~4000

|

|

|

Filler Scale (kg)

|

0.1~150

|

0.2~200

|

0.2~300

|

0.2~300

|

0.5~500

|

1~600

|

|

|

Asphalt Scale (kg)

|

0.1~150

|

0.2~200

|

0.2~300

|

0.2~300

|

0.5~500

|

1~600

|

|

|

Fillet Elevator (T/Hr)

|

12

|

12

|

15

|

18

|

30

|

36

|

|

|

Screw Feeder (T/Hr)

|

10~24

|

12~16

|

22

|

27

|

27

|

36

|

|

|

Filler Bin (m3)

|

0.5

|

0.5

|

0.75

|

0.9

|

0.9

|

1.2

|

|

|

A/P Spray Pump (ℓ/Min)

|

300

|

500

|

700

|

900

|

1100

|

1400

|

|

|

A/P Transfer Pump (ℓ/Min)

|

250

|

300

|

300

|

300

|

300

|

300

|

|

|

A/P Supply Pump (ℓ/Min)

|

300

|

300

|

500

|

500

|

900

|

1100

|

|

|

Asphalt Tank (ℓ/SET)

|

30,000 x 1

|

30,000 x 2

|

30,000 x 2

|

30,000 x 2

|

50,000 x 2

|

20,000 x 3

|

|

|

Fuel Tank (ℓ/SET)

|

20,000 x 1

|

25,000 x 1

|

25,000 x 1

|

25,000 x 1

|

30,000 x 1

|

30,000 x 2

|

|

|

Diesel Tank (ℓ/SET)

|

4,000 x 1

|

4,000 x 1

|

4,000 x 1

|

4,000 x 1

|

10,000 x 1

|

20,000 x 1

|

|

|

Hot Oil Heater (kcal x SET)

|

600,000 x 1

|

860,000 x 1

|

860,000 x 1

|

860,000 x 1

|

860,000 x 1

|

860,000 x 2

|

|

|

Mixer (kg / batch)

|

Twin Shaft Pugmill Type

|

||||||

|

800

|

1,000

|

1,550

|

2,000

|

3,000

|

4,250

|

||

|

Air Compressor (ℓ x Min)

|

1,058

|

1,527

|

1,527

|

1,627

|

1,909

|

2,518

|

|

|

Temperature Recorder

|

3Point

|

3Point

|

3Point

|

3Point

|

3Point

|

4Point

|

|

|

Control Panel

|

Automatic System Computer Panel

|

||||||

|

Total Power(Kw)

|

WET

|

190.65

|

215.45

|

305,35

|

376,55

|

450,75

|

539,75

|

|

B/F

|

193.35

|

219.15

|

309,05

|

393,35

|

470,75

|

563,75

|

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- AHN, SANG-CHEOL

- Address

- 15-2 Koju-ri, Paltan-myon, Hwasung-city, Kyongki-do, 445-910, Korea

- Product Category

- Other Machinery & Industry Equipment

- No. of Total Employees

- 1-50

- Company introduction

-

Taeshin Corporation is Korea's leading manufacturer and exporter of complete equipment of Spun Prestressed Concrete Pole and Pile, Concrete Batching Plant and Asphalt Mixing Plant.

Each of SPC POLE and PILE production equipment are not built to be something to every customers. But everything are built to someone as tailor-made equipment for customers of SPC POLE and PILE production.

- Main Markets

-

Malaysia

Malaysia

Viet Nam

Viet Nam

- Main Product

South Korea

South Korea