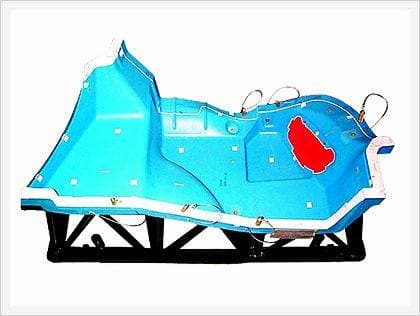

Automotive Check Fixture

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Vehicle Accessories

Sinhwa Tech Co., Ltd

- Verified Certificate

-

17

| Product name | Automotive Check Fixture | Certification | - |

|---|---|---|---|

| Category | Other Vehicle Accessories | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

We are the renowned global leader in Automotive Check Fixture, Auto Mold Parts, Molded Auto Parts. The wide range of product including Automobile Jig.

Automotive check tools, fixture, gauges, and inspecting equipment for checking automotive parts built by the tool and die industry.

We have been building and designing check fixtures and gauges for over 14 years.

Our customers expect quality inspection tools. Quality has been our history and will be our future. Your best source for finding automotive check fixtures suppliers.

We can supply a variety of car chacking fixtures for all types of car bodies.

Sinhwatech mold department has achieved many auto parts projects.

We use advanced 2D & 3D software for building complex surface plastic products.

During the process, we select the most suitable machining equipments and machining methods in order to get excellent mold body. The appropriate hot runner system guarantees even melting flow filling in the mold, and also yields less plastic waste.

Mover over, to meet different machining and the life of the mold request, number of high quality mold steels are used to build different parts of the mold.

|

Checking Fixture for Car Interior

|

Mold & Checking fixture for Car interior parts :

- Press molding Mold

- Simultaneous forming Mold

- Trimming & Piercing Mold

- Vacuum forming Mold

- Checking fixture & Jig

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Choi Jin-Ho

- Address

- 20, Maegoksaneop 6-gil, Buk-gu, Ulsan, South Korea

- Product Category

- Car Mats,Molds,Mould Design & Processing Services,Other Car Accessories

- Year Established

- 1994

- No. of Total Employees

- 1-50

- Company introduction

-

Since the industrial revolution in the 18thcentury, mold technology has developed for mass production

tools, and is now the basis of all manufacturing industries.Especially for the automotive industry of

nowadays, mold technology is the most essential and indispensable aspect of production tools.

SINHWA TECH has grown dramatically since its establishment by SINHWA MODEL in 1994.

SINHWA MOLD produced master models and mock-ups that was considered as the basis of mold

technology. It changed its company name to SINHWA TECH CO., LTD., and has concentrated its efforts to

develop thermal forming molds for auto interior parts. As a result, SINHWA TECH has 12 patents on vehicle

interior thermal forming molds, and performs various research and development programs run by the

government and civil organizations.

With the mold manufacturing technology and know-how accumulated for the last 20 years, SINHWA has

ranked as the top interior mold manufacturer in Korea. It supplies its molds to not only Korean auto interior

parts manufacturers but also foreign manufacturers in the U.S., China, Turkey, Czech Republic, Malaysia, etc.

In addition, since 10 years ago, SINHWA has been exporting molds to Japan every year, and was recognized

by a Japanese car interior parts manufacturer that is known as being most fastidious about quality.

To meet the higher demand for high tech mold, SINHWA established a new modern factory and office

building in the new industrial complex in Maegok, Ulsan. In SINHWA’s R&D center, experienced engineers

design molds using the latest designing tool software. Moreover, the new factory, which is 6000 square

meters wide, is fully equipped with various machineries necessary for mold manufacturing, such as twelve

5-axis high speed machining centers, mills, lathes, drilling and welding and assembly machines.

Also, with SINHWA TECH’s two electric ovens and 200 ton & 300 ton hydraulic press machines for

the try-outs of assembled mold, SINHWA has established a consistent manufacturing system for mold

designing, machining, and assembling for try-outs.

We, SINHWA TECH, will do our best to satisfy customer’s requirement for technology and quality while

ensuring reasonable price and quick delivery at the same time. We will share our creation of future myths

and success story with you.

- Main Markets

-

China

China

India

India

Indonesia

Indonesia

Japan

Japan

Malaysia

Malaysia

- Factory Information

-

Sinhwa Tech Co., Ltd.,

Sinhwa Tech Co., Ltd.

- Main Product

Related Products

KOREA GENUINE MOBIS OIL(AUTO LUBRICANT) 05200-484A0 (4L)

Korean Car Accessories

Spare Parts for Kia Cars

Anti loose self locking nut

KB30318400A Genuine Hyundai Kia Starter for Kia Pride

South Korea

South Korea