Gas Diffusion Layers(GDL)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Battery Packs

JNTG

- Verified Certificate

-

13

| Product name | Gas Diffusion Layers(GDL) | Certification | - |

|---|---|---|---|

| Category | Battery Packs | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

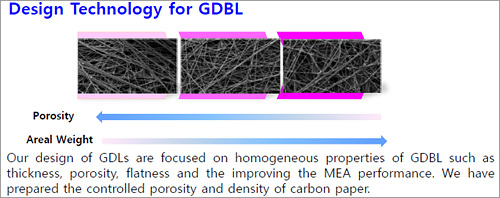

GDLs based on non-woven substrate are designed to enhance mass transfer of the fuel and byproduct through controlling pore distribution in the micro-porous layer and the property of GDBL. And GDLs have been designed to decrease the interfacial resistance between the catalyst layer and bipolar plates. Our concerns are focused on the homogeneous properties of GDL such as thickness, pore distribution, porosity, flatness and so on.

Manufacture of GDL

GDLs of the fuel cell are made up the GDBL and micro porous layer(MPL) that is consisted by carbon black and binder. GDLs engender hydrophobic property through the hydrophobic polymer treatment of the GDBL, we have controlled the PTFE content 5 to 40wt% in GDBL.

Specification

|

Unit

|

JNT-20-A1

|

JNT-30-A1

|

JNT-40-A1

|

||

|

Areal Weight

|

g/m2

|

100±5

|

110±5

|

140±5

|

|

|

Thickness(at 25kPa)

|

um

|

270±20

|

320±20

|

420±20

|

|

|

PTFE Contents in GDBL

|

%

|

10

|

10

|

10

|

|

|

Electrical Resistivity

|

mΩcm2

|

<20

|

<20

|

<20

|

|

|

Application

|

Portable DMFC

Transfer PEMFC |

Stationary PEMFC

|

Electrolysis

Redox Battery |

||

We can supply the controlled MPL structure of GDL by customer…s need and condition.

- JNT-20 based GDL have thin thickness and good MEA performances, specially DMFC system.

- JNT-30 based GDL have been designed for the stationary FC system and show good MEA performance at high humidified fuel condition.

- JNT-40 based GDL have about 400., the low compressibility and bending stiffness. And JNT-40 based GDL offer high density and the improved mechanical properties. MEA performance with JNT-40 based GDL show good at low humidified fuel condition because of the well-designed water management structure.

Suggested Users

- Fuel Cell

- Redox Battery

- Electrode for Electrochemical Reaction

Availability

- Sheet Samples: 280mm x 300mm

- Roll Products: 10~100m(280mm W)

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Tae Nyun Kim

- Address

- 235-36, Manyeonro, Jeongnammyeon, Hwaseong-siGyeonggi-do,

- Product Category

- Air Filter,Carbon Paper,Other Batteries

- No. of Total Employees

- 1-50

- Company introduction

-

In connection with GDL, we are constructing an evaluation system in relation to the Line capability of manufacturing the Roll firsthand where all processes are involved in the stage of spraying the carbon veil, GDBL, and micro-porous layer. We are committed to becoming the leader in supplying a variety of Roll form products.

With regard to polyelectrolyte type fuel cell, performance of MEA is very dependent on characteristics of the GDL, influenced especially by structure and composition of the micro-porous layer. JNTG has many years of experience in designing micro-porous layers to improve the MEA performance in various evaluation conditions. Also, we are conducting a research based on the relationship between micro-porous layer structure and the catalyst layer to optimize the MEA structure. We have developed the micro-porous layer having a dual structure in the GDBL to enhance transference of fuel and by-product matters in addition to the technology for enhancing the MEA performance in low humidity conditions

Carbon Fiber nonwoven veil is an essential product used in GDL of the hydrogen fuel cell and carbon paper which is used for electrochemical reaction. JNTG has the research infrastructure and production line that can continuously supply products to various sectors requiring durability and electro-conductivity, as well as Polymer Electrolyte Membrane Fuel Cell (PEMFC) and Direct Methanol Fuel Cell (DMFC) fields.

- Main Markets

-

Germany

Germany

Japan

Japan

Singapore

Singapore

U.S.A

U.S.A

- Main Product

South Korea

South Korea

_2.jpg)