Gambo Bag

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Packaging

Korima Ind. Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Gambo Bag | Certification | - |

|---|---|---|---|

| Category | Other Packaging | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Features

After it is filled, standard FIBC becomes cylindrical in shape due to the affect of the filled material.

This is where the Gambo is far more advantageous as when it is fully loaded, it keeps its original shape, being more cubical or rectangular rather than cylindrical.

As a result; Gambo has gained in importance, and its usage & production has greatly increased. Because Gambo has plain sides when they are arranged side by side, there are no gaps.

That is the reason why it's possible to transport and stock more product by using Gambo instead of Standard FIBC, So, when we compare Gambo to Standard FIBC, we can see that for the same volume, it is possible to transport & stock 16-23% more product with Gambo.

Optimal payload

- Standard FIBC

Palette area 1.15 x 1.15 = 1.32 m2 FIBC floor area π x (1.15 / 2) 2 = 1.04 m2 Efficiency 1.04 / 1.32 = 78% Loss ratio 22% Total loss ratio 25 to 32 % Standard FIBC Tota

l Efficiency68 to 75 % - Gambo FIBC

Palette area 1.15 x 1.15 = 1.32 m2 Gambo floor area 1.22 m2 Efficiency 1.22 / 1.32= 93% Volume loss 7% Total loss ratio 7 to 10 % GAMBO Total

Efficiency90 to 93 %

- 3 Types of general bag size

- 115 x 115 cm (filled size), 20 , 40 ft container standard

- 100 x 120 cm (filled size), truck or container standard

- 80 x 120 cm (filled size), truck or train transportation stand

- 3 Types of general bag size

- Standard FIBC ( Standard FIBC stack in container)

- GAMBO FIBC ( GAMBO Styled bag stack in container)

- Quantity of loaded Gambo bag (1story load case)

Truck 1220 x 240 x 240 cm (L x W x H ) 20 Gambo FIBC 115 x 115 cm 24 Gambo FIBC 100 x 120 cm 30 Gambo FIBC 80 x 120 cm

20ft Container 592 x 234 x 239 cm (L x W x H ) 10 Gambo FIBC 115 x 115 cm 10 Gambo FIBC 100 x 120 cm 10 Gambo FIBC 80 x 120 cm

40ft Container 1203 x 234 x 239 cm (L x W x H ) 20 Gambo FIBC 115 x 115 cm 20 Gambo FIBC 100 x 120 cm 24 Gambo FIBC 80 x 120 cm

* Caution : 20ft or 40ft container entrance height 227 - 229 cm

Improved stability

For FIBC Bags, the stability depends on correlations with content's features, area and height of packaging.

Gambo FIBC sustains square or rectangle tight shape. Bottom side of the bag is 30% larger than the standard FIBC. Improved stability comes from this reason.

|

|

|

| Comparing Changes While filing | 3 story topped Gambo FIBC |

Stability improvement gives great merits on various products.

Gambo FIBC is easy to slide in to deal resins which has to be treated carefully.

Efficient use of storage space

Gambo FIBC shape, square or rectangle sustain the form. Improved stability keep storage space loss. Appropriately stack in a warehouse.

|

|

Compare Gambo & FIBC filled with Talc powder in a warehouse. |

Form fastness

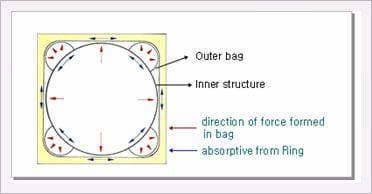

Gambo FIBC form fastness when filled. 80% of loaded product maintained by inner bag. Never change it's square, rectangle shape in any circumstances.

Safety, strength and product protection

Gambo FIBC is formed bag-in-bag style. Inner bag is made with PP woven cloth sewed with outer bag. Inner bag holds most of the product load. Outer bag is enough to hold the style. Excellent in dust protection.

Bag-in-bag is highly structured by using this overlap style for outside impact.

Inner bag is sewed edge overlapped with outer bag. This way, it strongly holds when lifted.

Also manufactured considering stability when drop. Leak nor any damage Occur when drop. This is certified with falling test. All the above features are certified with UN authentication.

|

|

GAMBO bag-in-bag structure Gambo FIBC Filled with PE granule |

Customer-friendly packaging

Packaging take important role in company's sales & marketing.Customers would like to undertake with securely packed product. Also well packed product is easy to load and treat.

Gambo FIBC is well manufactured neat and tidy considering your sales & marketing.

|

|

|

| container / truck behind observation | Unloading from 20ft container |

Environmentally-friendly packaging

3 essentials considering environment.

- What is used to make this packaging?

Sewed Gambo FIBC is made from Polypropylene. Polypropylene is recyclable and can be incinerate without any environ affect. - How much do you material use to make this packaging?

Gambo FIBC use similar amount of PP with standard FIBC. - Reusing packaging itself

Gambo FIBC is manufactured to reuse easily.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Yong-ho, Chai

- Address

- Rm. 1818, Nasan Officetel, 13-3 Gaepo-dong, Gangnam-gu, Seoul, Korea

- Product Category

- Other Packaging

- No. of Total Employees

- 101-500

- Company introduction

-

Thank you for visiting Korima Ind. Co., Ltd. Website. We are very happy to greet you through cyber. This site will introduce our packaging material and also will provide updated information on our industry. We would like to provide a cyber place where all our customers could share information together.

We would like to recollect the course with our valuable customers what we have followed for 11years. You would realize that we are a company who never changes our true loyalty toward our customers.We have established in 1990 with foundation ideology as 'Creating harmony among men', 'Technology Development', 'Loyalty'. We are proud that our product has done well protecting customer’s product economical way and delivering all over the world. We have faced many hard times but we have overcome all those barriers and finally well known as a leading company in the industry.

Our motto is 'Moving forward together with customer'. We will not satisfy our current stability, we will take-off toward a 2nd stage challenging into a global market. And we hope to have this challenge with you. We will do our best and continue developing our product while leading FIBC industry.

- Main Markets

-

China

China

- Main Product

Related Products

ETHYLENE GAS ABSORBER

Flexible packaging materials-Retortable pouch

Spout Pouches

Shaped pouch

ALU/ALU Cold Formina Film