zirconia ceramic foam filter / alumina ceramic foam filter / silicon carbide ceramic foam filter

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- INNOVACERA

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- ceramic foam filter, alumina ceramic foam filter, silicon carbide ceramic foam filter, zirconia ceramic foam filter

- Category

- Machinery & Parts

INNOVACERA

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

13

| Product name | zirconia ceramic foam filter / alumina ceramic foam filter / silicon carbide ceramic foam filter | Certification | - |

|---|---|---|---|

| Category | Machinery & Parts | Ingredients | - |

| Keyword | ceramic foam filter , alumina ceramic foam filter , silicon carbide ceramic foam filter , zirconia ceramic foam filter | Unit Size | - |

| Brand name | INNOVACERA | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

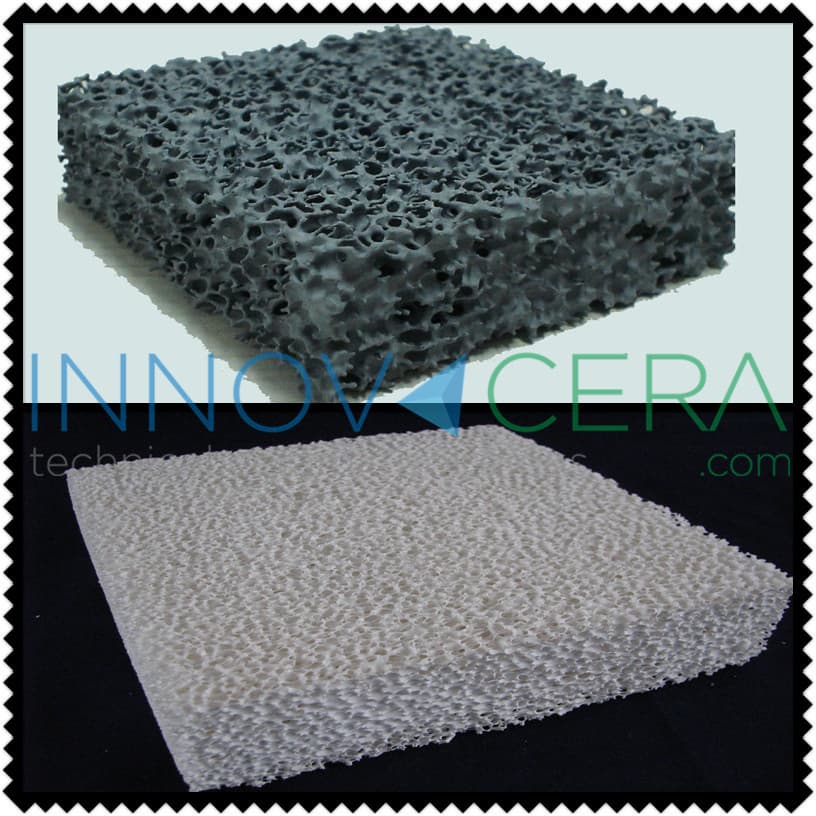

1. Alumina Ceramic Foam Filters

Alumina Ceramic Foam Filters are mainly applied for filtration of aluminum and aluminum alloys in foundries and cast houses . With their excellent resistance to attack and corrosion from molten aluminum, they can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Alumina ceramic foam filter can be made by specific procedures and have peculiar bone-frame holes just like the shape of foam(Called three-dimensional connected channel) and myriad eyelets which only been found in big times microscope. Compare to similar ones, our products have many advantages as below:

v Stable chemical composition

v Excellent strength

v Resistant to high temperature

v Calm down of the turbulent flow of metal nicely

v big m2/m3

v Superior dimensional tolerances: +0/-2.5

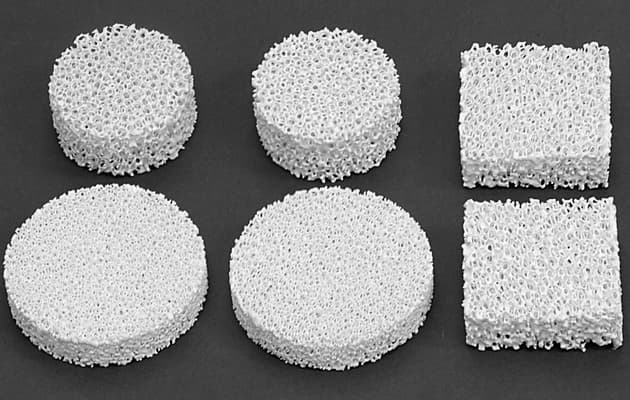

2. Standard size: (we can also customize the size according to your requirement)

§ 178x178x50 mm or 7'' x7''x2'' (10--60ppi)

§ 229x229x50 mm or 9'' x9'' x2'' (10--60ppi)

§ 305x305x50 mm or 12'' x12'' x2'' (10--60ppi)

§ 381x381x50 mm or 15'' x15'' x2'' (10--60ppi)

§ 432x432x50 mm or 17'' x17'' x2'' (10--60ppi)

§ 508x508x50 mm or 20'' x20'' x2'' (10--60ppi)

§ 584x584x50 mm or 23'' x23'' x2'' (10--60ppi)

3. More information

Alumina Ceramic Foam Filter has the advantages of high porosity, low loss of thermal shock, high mechanical strength at normal and high temperature, large specific surface, good chemical stability and excellent filtering functions of screen, filtering residuum collection and adsorption especially for tiny impurity of 1~10μm.

The three-dimensional structure can improve the cast quality in large scale by changing the molten metal from turbulence flow to lamellar flow, removing the gas and smoothing the casting. Ceramic foam filter is not only applied for molten metal filtering in high temperature, but gas treatment in high temperature, carrier of catalyzer, solid heat exchange and advanced filling for chemical industry.

4. Physical Properties:

| Working Temperature | ≤1200°C |

| Porosity | 80~90% |

| Compression Strength (Room Temperature) |

≥1.0Mpa |

| Volume Density | ≤0.5g/cm3 |

| Thermal Shock Resistance | 800°C---room temperature 5 times |

| Application | non-ferrous and alumina alloys, high temperature gas filter, chemical fillings and catalysis carrier etc. |

| Al2O3 | SiC | SiO2 | ZrO2 | Others |

| 80~82% | --- | 5~6% | --- | 12~15% |

6. Application of Ceramic Foam Filter:

Innovacera can supply many kinds of ceramic parts according to the customers' differents requirements.

| Manufacturing Options | Advanced Finishing Services |

|

Injection molding |

Precision grinding and lapping |

| Roll compacting | Laser machining |

| Extruding | Engineering design and support |

| Co-firing | Metallizing |

| Isostatic pressing | Ceramic-to-metal brazing |

| Dry pressing | Specialized coatings |

| Hot pressing | Threaded components |

| Tape casting | Precision motion components |

| Slip casting | Complex clean room assemblies |

Our own factory: located in Zhangzhou, Fujian - one hour drive from Xiamen

Certifications: ISO 9001-2008, ISO14001-2004, OHSAS 18001-1999

Export office: located in the Special Economic Zone - Xiamen

Other popular products: Tubes, Balls, Honeycomb, Seals, Beads, Substrates, Rollers etc.

Welcome to visit us, if you have any demand or inquiry, please feel free to contact us!

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Chandler Tsai

- Address

- RM615, No.398 Jiahe Road, Huli District, Xiamen, China 361006

- Product Category

- Ceramics,Oxide

- Main Product

_2.jpg)