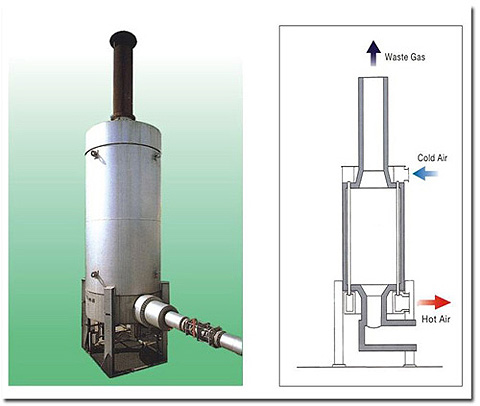

Recuperator (Cage Type)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Korea Thermal Engineering Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Recuperator (Cage Type) | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Features

- Bending type recuperator is composed of many steel tubes and is mounted in flue gas duct of industrial furnacess to preheat combustion air and/or gas.

- In this recuperator, the flue gas flows throught outside of tubes and the air flows through in side of tubes, under maximum flue gas temperature of 750 °C, gaining maximum preheated air temperature is 600°C.

- But this recuperator maintenance is some more difficult than general channel type recuperator and is more widely used in chemical plant than reheating furnace for steel and non ferrious reheating furnace and is not suitable for abrupt load variations of rurnace.

- It is more suitable for the furnace using clean energy than austenite tubes for heat transferring that is very weak in the mentioned circumstance.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Sang Hee, Moon

- Address

- K-Tec Bldg., 298, Gajwa-ro, Eunpyeong-gu, Seoul, Korea

- Product Category

- Other Machinery & Industry Equipment,Water Treatment

- No. of Total Employees

- 1-50

- Company introduction

-

Korea Thermal Engineering Co., Ltd. has long been engaged in the design and manufacture of "heat recovery systems", namely recuperators for use in conjunction with furnaces in all industrial fields, but especially the steel industry.

To date, we have delivered over 3,000 units. Our long service-life design, based on accurate heat calculation and the selection of optinum heat resistant steels has earned an established reputation, as proven by our outstanding delivery record. We constantly adopt the latest technology from a wide range of fields.

Since the escalation in petroleum prices, industry has been taking steps to conserve energy by placing emphasis on fuel economy. In recent years, efforts have also been made for protection of the environment.

K-TEC's wide range of recuperators provide a heat recovery system which effectively utilizes waste heat to preheat combustion air and fuel gases and reduce fuel costs, while, as the result of fuel saving, contributing environmentally to a reduction in carbon dioxide (CO2) emissions.

Consequently, the recuperator is effective in energy conservation in a variety of industrial furnaces, offering positive fuel savings as well as reducing the amount of CO2 gas discharge into the atmosphere, one of the causes of the "Greenhouse" effect."

- Main Markets

-

Indonesia

Indonesia

Japan

Japan

Taiwan

Taiwan

U.S.A

U.S.A

- Main Product