Desander/Decanter

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Construction Machinery

JUN Engineering Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

13

| Product name | Desander/Decanter | Certification | - |

|---|---|---|---|

| Category | Other Construction Machinery | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

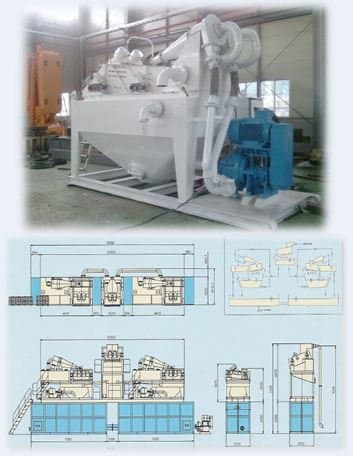

Desander

Desander is desanding equipment for diaphragm wall construction.

Using the bentonite slurry to protect the bored trench or hole.

Eliminating the remains (gravel, sand, mud) from the fusion (bentonite and bentonite slurry are mixed) by centrifugal separation method of the desander's a various cyclone and mesh / vibration of the screen.

Excellent effectiveness is available when reusing the bentonite slurry.

Decanter

Slurry, contaminated with soil particles, is pumped into the hub of a rotating conveyor screw and passes into the rotating bowl sur-rounding the conveyor through ports in the conveyor hub, where the solids are separated out from the fluid by the centrifugal forces and deposited on the

bowl wall.

Due to a slight difference in the speed of rotation of the conveyor screw and the bowl, the conveyor screw continuously conveys the solids along the bowl wall to the solids discharge port, whilst the clarified liquid is continuously discharged in the opposite direction.

Specification

|

Desander

|

Decanter

|

||

|

Capacity

|

120~500m3/h

|

Capacity

|

50m3/h

|

|

Max. Mud Density

|

1.18ton/m3

|

Motor

|

60HP x 4P

|

|

Pump

|

22~45x2kW

|

Pump

|

5HP x 0.77m3/min

|

|

Piping

|

4~6x2Inch

|

Bowl Speed

|

1750rpm

|

|

Vibrator

|

1.5x2~2x6kW

|

Bowl Dia.

|

640mm

|

|

Cyclone Dia.

|

425~450x2mm

|

Width

|

2438mm

|

|

Sieve Area

|

2.4~3.6m2

|

Height

|

2600mm

|

|

Coarse Sieve Mesh

|

5x25

|

Length

|

5000mm

|

|

Fine Sieve Mesh

|

0.4x25

|

Weight

|

11ton

|

|

Weight

|

3.5~11.5ton

|

||

Applications

For slurry treatment in ;

- Foundation Construction.

(Diaphragm-Wall Construction, Reverse Circulation Drilling, Tunneling, etc.)

- Environmental Application.

(Cleaning System for Oil and Gas Industries, Sludge thickening and dewatering, Waste Treatment, etc.)

- Food and Chemical Industries.

According to respective requirement by environmental treatment plant,

Regeneration of slurries/Treatment of waste slurries

Soils of particle size <10μm (fine silts and clays) can't be separated out from the bentonite slurry by mechanical methods due to their very similar particle structure. Separation of such slurries into clear water and solid is achieved with the use of chemical additives which cause the fine soil particles to flocculate into larger flocculent masses (Polymers) which are separated out form the water as solid by secondary centrifuge. The regeneration rate and throughput capacity of the decanter centrifuge depend on ; - Speed of the conveyor screw and bowl of 1600 to 2000rpm.

- Particle size distribution of the soil particles suspended in the slurry.

- Specific gravity of the contaminated slurry.

- Viscosity of the slurry to be regenerated.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Dong-Jun Kim

- Address

- #2001-5, Ahnha-ri, Hanrim-myun,, Gimhae-si, Gyeongsangnam-do, Korea

- Product Category

- Home & Kitchen,Machinery Tools,Mining Machinery Parts

- No. of Total Employees

- 1-50

- Company introduction

-

Based on "Technical Innovation" spirit, this company was established in 2010.

Which has been manufacturing and supplying various types of drilling & boring equipment such as TBM(Shield & Semi-Shield), RCD(Reverse Circulation Drilling Machine), Casing Oscillator, DCM(Deep Concreting Method), Powerpack, Desander, Decanter, Hammer Grab, Hang Grab, Casing Joint/Shoe, Tools & others.Our division operate a highly equipment-supply system, powered by one of the most the optimized design, reliable structure/strength analysis, perfect quality.

JUN Engineering Co., Ltd. Strives to R & D the equipment that meet the needs and expectations of our customers. By customer's needs and market environment onto policies, the division today easily competes with the world's top companies. All of our employees and executives will do utmost best to make our equipment and service improve even further.

We sincerely appreciate our customers. They have been closely following the growth of the JUN Engineering Co., Ltd. With affection and interest. We Promise to repay their dedication with excellence Equipment and Techniques.

- Main Product