RCD (Reverse Circulation Drilling)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Construction Machinery

JUN Engineering Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

13

| Product name | RCD (Reverse Circulation Drilling) | Certification | - |

|---|---|---|---|

| Category | Other Construction Machinery | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

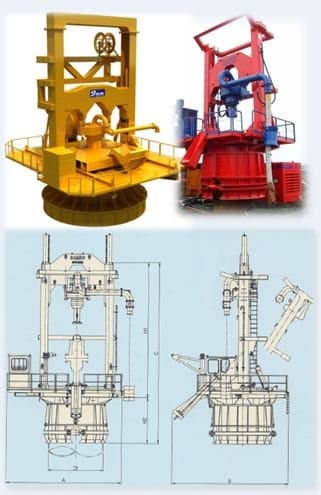

RCD(Reverse Circulation Drilling) Machine

R.C.D Machine is large bored equipment of soil foundation works for bridges, buildings and subways and used for the vertical excavation work by means of the installed power swivel with rotary bits on body based on hydraulic system.

It brings the rapid enhancement of work efficiency according to speedy excavation capability without noise and vibration and is not influenced by the nature of soil. Vertical work capability is over 50M deep-hole drilling and almost not influenced by any working environments.

Specification

|

Drilling Dia.

|

1.5~3.0m

|

|

Swivel Torque

|

241~341kN-m

|

|

max. Drilling Speed

|

32.7~34.3rpm

|

|

Cont. Drilling Speed

|

6.5~6.9rpm

|

|

Pull Down Force (Pull up)

|

129~201ton

|

|

Pull Down Force (Thrust)

|

88~122ton

|

|

Mast Tilt Angle

|

22~32°

|

|

Platform Tilt Angle

|

16°

|

|

Required the Air Supply

|

7~25m3/min

|

|

Weight

|

59.3~81.8ton

|

|

(Drill String-50M)

|

*RCD machine is essential for the drilling.

This equipment is used for drilling a borehole through soft and hard rack layers .

- Apply to bridge, pile constuction.

Option

1. Power Pack

|

Engine Power

|

260~850HP

|

|

Weight

|

7~20ton

|

- Manufacturing to use in foundation construction equipment (R.C.D M/C, Casing Oscillator, Hydraulic Hang Grab etc.) is possible.

- According to reducing noise to the minimum by efficient soundproof, working in a down is possible.

- Reducing fuel consumption rate to the minimum by minimum

2. Drill Bit

|

Casing Dia.

|

1.0~3.0M

|

|

Drill Bit Dia.

|

0.85~2.75M

|

|

Body Length

|

1500~2500mm

|

|

Suction Pipe

|

NW200~300

|

|

Roller Cutter Size

|

8~12inch

|

|

Roller Cutter No.

|

6~21EA

|

|

Weight

|

1.5~12.5ton

|

|

Cutter Type

|

Tooth/Button/Disc

|

|

Assembly with

|

Drum Stabilizer

|

|

Heavy Duty Stabilizer

|

|

|

Heavy Duty Space Pipe

|

|

| *The above may change during further development | |

Schematic Diagram

|

1. Mast Boom

|

10. Drill Pipe

|

|

2. Working Platform

|

11. Drill Pipe Connector

|

|

3. Adapter

|

12. Space Pipe

|

|

4. Casing Clamp

|

13. Double Stabilizer

|

|

5. Slide Box

|

14. Drum Stabilizer

|

|

6. Gear Box(Power Swivel)

|

15. Bit Body

|

|

7. Operation Line

|

16. Bits

|

|

8. Suction Line

|

17. JID Crane

|

|

9. Single Sttabilizer

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Dong-Jun Kim

- Address

- #2001-5, Ahnha-ri, Hanrim-myun,, Gimhae-si, Gyeongsangnam-do, Korea

- Product Category

- Home & Kitchen,Machinery Tools,Mining Machinery Parts

- No. of Total Employees

- 1-50

- Company introduction

-

Based on "Technical Innovation" spirit, this company was established in 2010.

Which has been manufacturing and supplying various types of drilling & boring equipment such as TBM(Shield & Semi-Shield), RCD(Reverse Circulation Drilling Machine), Casing Oscillator, DCM(Deep Concreting Method), Powerpack, Desander, Decanter, Hammer Grab, Hang Grab, Casing Joint/Shoe, Tools & others.Our division operate a highly equipment-supply system, powered by one of the most the optimized design, reliable structure/strength analysis, perfect quality.

JUN Engineering Co., Ltd. Strives to R & D the equipment that meet the needs and expectations of our customers. By customer's needs and market environment onto policies, the division today easily competes with the world's top companies. All of our employees and executives will do utmost best to make our equipment and service improve even further.

We sincerely appreciate our customers. They have been closely following the growth of the JUN Engineering Co., Ltd. With affection and interest. We Promise to repay their dedication with excellence Equipment and Techniques.

- Main Product

Related Products

MPSystem Robot Parking - MetroLift

Aerial Work Platform - Boom Lift Truck HS380

DTH BIT

KOMATSU EXCAVATOR SPARE PARTS

Hydraulic Breaker Alicon B210 (Excav. 18~25T)