CaCO3

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Chemicals

SAEWHA Industrial Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | CaCO3 | Certification | - |

|---|---|---|---|

| Category | Other Chemicals | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

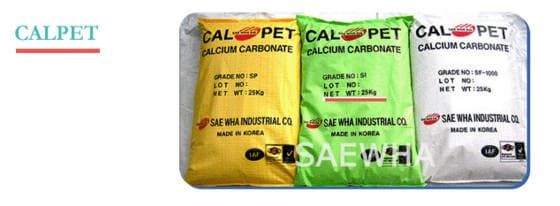

CALPET

- CALPET is a kind of masterbatch, composed of 85% Calcium carbonate(CaCO3) and besides specially blended polyethylene resins.

- CALPET is used by mixing polyethylene resins(LDPE, HDPE, PP resins) and used 5~70% accordingly goods(operating condition)

- You can enjoy the follwing benefits by using CALPET together with polyethylene resins : better printability, better productivity, better dimension stability, antivertical tearing, antifibrillation reduction of white color pigment cost, reduction of calorific quantity, etc...

CaCO3 M/B for incineratable [Hi, SUPER-1000] Photodegradable Film

- Incinerable & Photodegradable Film?

Incineratable and photodegradable film is manufactured by mixing appropriate quantities of resin with CaCO3 Master Batch, which contains over 80% inorganic compound(CaCO3). The use of and inorganic compound results in reducing environmental pollutants by over 70% when incinerated. - Principle & Effect of Photodegradation

Incineratable and photodegradable film is has 45% lower heat of combustion when incinerated compared to film made of common resins and does not combust as it contains a mineral (CaCO3). At about 800°C, the heat of combustion is lowered as the mineral decomposes into CaO and CaO2. Dioxin, sulfuric gas and choleric gas become neuralized when incinerated, which prevents air pollution.

As well, Photodegradation of the film begins after a year with exposure to sunlight and film slowly starts to decompose after 2 years even in a landfill. Furthermore, CaCO3 is decomposed by CO2, a metabolic material of microorganisms, and the moisture trapped in soil. - Financial Benefits of Incineratable & Photodegradable Film

The cost of incineratable and photodegradable film is over 40% less than that of common resins. Mixing ratios and the speed of decomposition may be adjusted easily to reduce costs. - Efficiency of Incineratable & Photodegradable Film

Using incineratable and photodegradable film for agricultural mulching minimizes costs compared to existing biodegradable mulching and eliminates the mechanical problems(reduced production volume, stickiness, post-cleaning, etc.) arising from making biodegradable film. Inventory management of biodegradable film is difficult as an extremely rapid decomposition speed(approx. 3 months) makes handling difficult, whereas, incineratable and photodegradable film keeps for about a year and decomposes slowly, making it applicable on an extensive range of products.

Combination Effects and Uses of Hi-SUPER-1000

|

Classifications

|

Combination Effects

|

Uses

|

|

Extrusion

|

-Elecgant surface and excellent ventilation -Clear printing -Reducing the wastes in incinerating or filling them in the land -The speed of photolysis adjustable through the combination rate -Cost reduction |

-Mulching film ofr agrisultural and industrial uses -Garbage bag -Disposable shopping bag -Tablecloth, D/M envelope -Other envrionmentally friendly films |

Calcium Carbonate M/B(CALPET) for General Extrusion and Ejaculation

|

Classifications

|

Combination Effects

|

Uses

|

|

Extrusion

|

-Excellence in preventing wastes pieces of yarn and printing clearly and vividly -Maximization in productivity from excellent cooling effects -Cost reduction -Reduction in molding contraction -High resistance against outer impact and excellent hardness -High-speed cooling -Cost Reduction |

-P.P., HDPE, Flat Yarn -Wooven Bag, tarpaulin -P.P. Sheet and Bands |

|

Ejaculation

|

-Reduction on molding contraction -High resistance against outer impact and excellent hardness -High-speed cooling -Cost reduction |

-P.P., seeding box, flower pots, chair, tables, vertical weights etc. |

Calcium carbonate M/B(CALPET) of Pipes and Sheets for Construction and Automobiles

| Classifications | Combination Effects | Uses |

|

Extrusion

|

-Excellence in preventing wastes pieces of yarn and printing clearly and vividly -Maximization in productivity from excellent cooling effects -Cost reduction -Reduction in molding contraction -High resistance against outer impact and excellent hardness -High-speed cooling -Cost Reduction |

-HDPE, Pipes -P.P. Sheets -Various Construction Materials |

CALPET

CALCIUM CARBONATE COMPOUND

Specification of CALPET

|

Testing Item

|

Unit

|

Test Method

|

Standard

|

|

Filler Content

|

%

|

600°C/2hr

|

85±1

|

|

Polyolefin Content

|

%

|

600°C/2hr

|

15

|

|

Density

|

g/cm2

|

ASTM D 467

|

1.90

|

|

Water & Moisture content

|

%

|

Coulometer

|

0.09

|

|

Pellet Size

|

mm

|

.

|

3±0.5

|

|

Color

|

.

|

.

|

White

|

|

Melt flow index(190°C)

|

g/10min

|

ASTM D 1238

21.16N |

13

|

|

CaCO3 Median Size

|

μ

|

.

|

High grade=2.5±0.5

High grade=5.5±0.5 High grade=10.5±0.5 |

|

Specific Gravity

|

g/cc

|

.

|

2.1

|

Mixing Ration & Application of CALPET

|

CALPET-Grade

|

Application

|

Mixing Rratio

Resins : CALPET |

|

CALPET-SD

|

(A)HDPE Yarn (B)LDPE Tarpaulin Coating |

5~15%

5~40% |

|

CALPET-SP

CALPET-SPC |

(A)PP woven Yarn (B)PP woven bag Coating |

5~25%

5~35% |

|

CALPET-SF1000

|

(A)HDPE Shopping bag (B)LDPE Shopping bag |

15~50%

10~40% |

|

CALPET-SI

|

(A)PP Injection Molding (B)LDPE Injection Molding (C)HDPE Injection Molding |

20~70%

20~50% 20~50% |

*The ratio of polyolefin and CALPET is vaious of operating condition.

*Injection and Blow moldings are different from the data according to their thickness and processing condition.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Oh, Jang-soo

- Address

- 42-168, Ihyeon-dong, Seo-gu, Daegu

- Product Category

- Industrial Supplies,LED Lighting,Plastic Product Making Machinery

- No. of Total Employees

- 51-100

- Company introduction

-

Welcome !

Welcome to our e-catalog home.

Here you can find information about our products. You can also send us inquiries and post comments about our company and products. We hope you enjoy your visit.

- Main Product

Related Products

B&B Baby Laundry Detergent

Lubricant(Engine Oil), Fully Synthetic, Synthetic, Mineral

TiO2 Photocatalyst

Scale Inhibitor

Power Dry-ux