STC ( ALUPIA, ISOPIA, SONOPIA )

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- STC (ALUPIA, ISOPIA, SONOPIA)

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

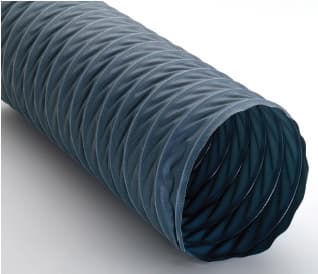

- fire retardent, flexible duct hose, hvac, ventilation

- Category

- Machinery & Parts , HVAC Systems & Parts

STC

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

14

| Product name | STC ( ALUPIA, ISOPIA, SONOPIA ) | Certification | - |

|---|---|---|---|

| Category |

Machinery & Parts

HVAC Systems & Parts |

Ingredients | - |

| Keyword | fire retardent , flexible duct hose , hvac , ventilation | Unit Size | - |

| Brand name | STC (ALUPIA, ISOPIA, SONOPIA) | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Advantage of our product

Inner Duct(Core) Materia

There are several materials used for flexible duct core. Generally, flexible duct is used inside buildings, do fire proof or retardant materials are mainly used. For outdoor ventilation, non-fire-retardant materials can be used. However, it would be risky and dangerous to use non-fire-retardant or proof materials for indoor purposes, for it may start fire. 2 or 4plies are standard, but to improve strength or rigidity, more than 4plies can be applied.

Basically, material will be determined according to the usages and applications of the flexible duct. The pressure drop may be influenced depending on the type of materials. The following are the main applications for each material:

·Heating & cooling Purpose : Aluminum Foil, Fiber Glass Fabric

·Outdoor Ventilation Purpose : Tarpaulin, PVC coated Tarpaulin

·Fire protection Purpose : Aluminum Foil, Aluminum

·Sound Absorption Purpose : Micro-Perforated Aluminum Foil, Spunbond

·Tunnel or Construction Site Ventilation Purpose : Special Tarpaulin

·Dispalying Application : Transparent PE film

·Hot Gas Application – Silicone Coated Fiber Glass Fabric

Copper-Coated Steel Wire

This is for making flexible duct into a round shape and keeping rigidity of the duct. This wire is metal materials, so it can be oxidized by moisture in the air. So the wire should be coated for a longer lasting life. And the wire helix distance normally connects with pressure loss. If the distance is long, an inner duct can be corrugated and cause a relatively big pressure loss. To prevent corrosion and to keep a long durability, the steel wire is coated with copper.

Adhesive

One of the most important and critical factors is adhesive, which binds inner duct materials and steel wires to make it strong. If the adhesive does not hold the core materials and the steel wires very well, this causes air leakage. Therefore, a good adhesive with strength and use of the proper method power is required.

The three ways of adhering are as follows:

·Hot Melting

The surface of a material is melted by momentary heat for binding. If the wire can be moved by the finger inside the adhered core, it would loose adhesive power under hot temperatures during the summer.

·Adhesion(Self-Hardening)

It would be difficult to melt the surface of metal materials such as aluminum or aluminum foil, so an adhesive is used in this case. The adhesive should be indurative, which never comes off once binded. Adhesive with viscosity agent is not recommended because this would break off at about 60℃ or higher.

·Clipping

This is used for silicone or spunbond, which the hot melting or adhesion method can not be applied. This is especially used for where it requires sanitary control such as hospitals.

Insulation Material

If there is a big temperature difference between the inside and outside of the duct, condensation occurs. To prevent condensation and to maintain the air temperature inside the duct, insulation is applied.

Among several insulation materials is glasswool, which is fire-proof and its lower heat conductivity widely used. This glass fiber is absolutely not an asbestos material, which is known as a cancer-inducer. Recently, a polyester insulation was used for easy work, Especially, this polyester insulation was widely used for clean rooms because of less dispersion of dust.

Vapor barrier (jacket)

This vapor barrier used for insulated flexible duct is to keep insulation fixed and prevent any moisture from penetrating inside the duct. Also, it is used for sound absorption duct to prevent any air leakage from the duct.

Generally, aluminum is the most popular material for vapor barrier. Recently, a polyester material was applied, which is better against salt.

ALUPIA611-A611

Adhesive Strength

Hot-melt type adhesive-vulnerable to heat and moisture is not used, thus duct is strong.

Rigid Structure

It has 6-ply and 12.5mm wire distance to keep very rigid structure performance

Steel Wire

High tensile steel wires are suitable to each size to keep its performance and function perfectly.

Fire Resistance

This aluminum is noninflammable, and it’s not coated with PVC, thus in case of fire there is little generation of poisonous gas.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Foil |

Wire |

Adhesion |

||||||

|

ALUPIA 611

|

Aluminum Polyester Laminated |

High Steel Wire |

Self-Hardening Type |

-30℃~+140℃ |

-50mmWG~300mmWG |

Max 30m/sec |

10m/carton box |

2~18” (50~450mm) |

ALUPIA221

Adhesive strength

Hot-melt type adhesive-vulnerable to heat and moisture is not used, thus duct is strong.

Steel Wire

High tensile steel wires are suitable to each size to keep its performance and function perfectly. Copper-Coated type.

Elasticity & Smoothness

In case 10m product is compressed into 60cm for packing and then spread out for use, it would not be compressed again, thus there is little lose of pressure.

Fire Resistance

This aluminum is noninflammable, and it’s not coated with PVC, thus in case of fire there is little generation of poisonous gas.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Foil |

Wire |

Adhesion |

||||||

|

ALUPIA221

|

Aluminum Polyester Laminated |

High Steel Wire |

Self-Hardening Type |

-30℃~+140℃ |

-50mmWG~300mmWG |

Max 30m/sec |

10m/carton box |

2~18” (50~450mm) |

MEPIA222

Adhesive strength

Hot-melt type adhesive-vulnerable to heat and moisture is not used, thus duct is strong.

Steel Wire

Copper-coated high steel wires are bent to be suitable for the caliber of each size, thus the adhesive status of aluminum is perfect. Copper-coated type.

Elasticity & Smoothness

In case 10m product is compressed into 60cm for packing and then spread out for use, it would not be compressed again, thus there is little lose of pressure.

Fire Resistance

It’s fire-resistant, and it’s not coated with PVC, thus in case of fire there is little generation of poisonous gas.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Foil |

Wire |

Adhesion |

||||||

|

MEPIA 222

|

Metalized Polyester Laminated |

High Steel Wire |

Self-Hardening Type |

-20℃~+75℃ |

Max 150mmWG |

Max 20m/sec |

10m/carton box |

2~18” (50~450mm) |

PEPIA224-P224

Adhesive strength

Hot-melt type adhesive-vulnerable to heat and moisture is not used, thus duct is strong.

Steel Wire

Copper-coated high steel wires are bent to be suitable for the caliber of each size, thus the adhesive status of aluminum is perfect. Copper-coated type.

Elasticity & Smoothness

In case 10m product is compressed into 60cm for packing and then spread out for use, it would not be compressed again, thus there is little lose of pressure.

Fire Resistance

The surface is transparent, so it can be observed inside. And its light weight makes installation easy & quick

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Foil |

Wire |

Adhesion |

||||||

|

PEPIA 224

|

Polyester Film |

High Steel Wire |

Self-Hardening Type |

-20℃~+75℃ |

Max 200mmWG |

Max 20m/sec |

10m/carton box |

2~18” (50~450mm) |

ISOPIA2214-I2214

Adhesive strength

Hot-melt type adhesive-vulnerable to heat and moisture is not used, thus duct is strong.

Steel Wire

Copper-coated high steel wires are bent to be suitable for the caliber of each size, thus the adhesive status of aluminum is perfect. Copper-coated type.

Heat, Corrosion & Cold Resistance

Aluminum laminated with Polyester is used for resisting against heat and cold condition. It has also strong resistance against rust or corrosion, so there would be little change for longstanding.

Fire Resistance

It’s fire-resistant, and its not coated with PVC, thus in case of fire there is little generation of poisonous gas. It can be used for fire resisting application in clean rooms, department stores and other HVAC purposes.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Inner core |

Insulation |

Vapor Barrier |

||||||

|

ISOPIA 2214 |

Same as ALUPIA221 |

20mmT Polyester |

Seamless Tube |

-30℃~+140℃ |

-50mmWG~300mmWG |

Max 30m/sec |

10m/carton box |

2~18” (50~450mm) |

ISOPIA2211-I2211

Inner Duct

Inner Jacket is ALUPIA221, so it is air tight and no glass wool erosion into air stream.

Outer jacket (Vapor Barrier)

Seamless tube-form vapor barrier used for insulation, thus connecting part is never separated, and heat insulating effect is maintained until the life of duct expires.

Elasticity and Smoothness

In case 10m product is compressed into 1.5m for packing for delivery and then spread out for use, it would not be compressed again, thus there is little lose of pressure.

Fire Resistance

It’s fire-resistant, and it’s not coated with PVC, thus in case of fire there is little generation of poisonous gas.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Inner core |

Insulation |

Vapor Barrier |

||||||

|

ISOPIA 2211 |

Same as ALUPIA221 |

16Kg/㎥ 25mmT Glasswool |

Seamless Tube |

-30℃~+140℃ |

-50mmWG~300mmWG |

Max 30m/sec |

10m/carton box |

2~18” (50~450mm) |

ISOPIA2224-I2224

Adhesive strength

Hot-melt type adhesive-vulnerable to heat and moisture is not used, thus duct is strong.

Steel Wire

Copper-coated high steel wires are bent to be suitable for the caliber of each size, thus the adhesive status of aluminum is perfect.

Elasticity and Smoothness

In case 10m product is compressed into 1.5m for packing and then spread out for use, it would not be compressed again, thus there is little lose of pressure.

Fire Resistance

It’s fire-resistant, and it’s not coated with PVC, thus in case of fire there is little generation of poisonous gas.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Inner core |

Insulation |

Vapor Barrier |

||||||

|

ISOPIA 2224 |

Metalized PET Film ×2Ply |

20mmT Polyester |

Seamless Tube |

-30℃~+140℃ |

Max 200mmWG |

Max 25m/sec |

10m/carton box |

2~18” (50~450mm) |

ISOPIA2221-I2221

Adhesive strength

Hot-melt type adhesive-vulnerable to heat and moisture is not used, thus duct is strong.

Adhesive strength

Hot-melt type adhesive-vulnerable to heat and moisture is not used, thus duct is strong.

Elasticity and Smoothness

In case 10m product is compressed into 1.5m for packing and then spread out for use, it would not be compressed again, thus there is little lose of pressure.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Inner core |

Insulation |

Vapor Barrier |

||||||

|

ISOPIA 2221 |

Metalized PET Film ×2Ply |

16Kg/㎥ 25mmT Glasswool |

Seamless Tube |

-30℃~+120℃ |

Max 200mmWG |

Max 25m/sec |

10m/carton box |

2~18” (50~450mm) |

ISOPIA2243-I2243

Adhesive strength

Hot-melt type adhesive-vulnerable to heat and moisture is not used, thus duct is strong.

Steel Wire

Copper-coated high steel wires are bent to be suitable for the caliber of each size, thus the adhesive status of aluminum is perfect. Copper-coated type.

Heat, Corrosion & Cold Resistance

Aluminum laminated with Polyester is used for resisting against heat and cold condition. It has also strong resistance against rust or corrosion, so there would be little change for longstanding.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Inner core |

Insulation |

Vapor Barrier |

||||||

|

ISOPIA 2243 |

Same as ALUPIA221 |

16Kg/㎥ 25mmT Glasswool |

Seamless Tube |

-30℃~+140℃ |

-50mmWG~300mmWG |

Max 30m/sec |

10m/carton box |

2~18” (50~450mm) |

SONOPIA4211-S4211

Noise-Proof & Rigid Structure

Inner Core has 4-layers so it is very strong. For air-conditioning system which needs noise-removing, it provides highly efficient noise absorption effect which lows construction costs. Thanks to the special micro-perforated process, the noise of octave band frequency 63-4000Hz is reduced by 6-36dB which brings comfortable environmental conditions.

Heat & fire Resistance

Inner core is 4ply of ALUDEC, thus it is excellent in heat & fire-resistant. In case of fire there is little generation of poisonous gas. It can be used for fire resisting application in clean rooms, department stores and other HVAC purposes.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Inner core |

Insulation |

Vapor Barrier |

||||||

|

SONOPIA 4211 |

Micro-perforated In ALUPIA421 |

16Kg/㎥ 25mmT Glasswool |

Seamless Tube |

-30℃~+140℃ |

Max 300mmWG |

Max 30m/sec |

10m/carton box |

3~18” (75~450mm) |

SONOPIA2211

Noise-proof

For air-conditioning system which needs noise-removing, it provides highly efficient noise absorption effect which lows construction costs. Thanks to the special micro-perforated process, the noise of octave band frequency 63-4,000Hz is reduced by 6-36dB which brings comfortable environmental conditions.

Outer Jacket (Vapor Barrier)

Outer surface is seamless tube-form vapor barrier, therefore, air will never leak out.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Inner core |

Insulation |

Vapor Barrier |

||||||

|

SONOPIA 2211 |

Micro-perforated In ALUPIA221 |

16Kg/㎥ 25mmT Glasswool |

Seamless Tube |

-30℃~+140℃ |

Max 200mmWG |

Max 30m/sec |

10m/carton box |

3~18” (75~450mm) |

SONOPIA221

Adhesive strength

Hot-melt type adhesive-vulnerable to heat and moisture is not used, thus duct is strong.

Steel Wire

High tensile steel wires are suitable to each size to keep its performance and function perfectly.

Outer Jacket

Outer surface is seamless tube-form vapor barrier, therefore, air will never leak out.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Foil |

Wire |

Adhesion |

||||||

|

SONOPIA 221 |

Micro- Perforated in ALUPIA221 |

High Steel Wire |

Self-Hardening Type |

-30℃~+140℃ |

Max 150mmWG |

Max 30m/sec |

10m/carton box |

3~18” (75~450mm) |

SONOPIA2211-F

Application

Special film for scatter-proof and sound-proof is used. It’s ideal for special facilities property is the same as that of SONOPIA2211. Inner Duct is encapsuled with a very thin OPP or PET film, thus no dust or moisture does not come out the insulation.

Features

In case it is used in humid areas such as bathroom, rest room, etc. The glasswool does not collect moisture. Therefore sound proof property is not increased bacteria, mold and other harmful micro organism can be prevented.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Inner core |

Insulation |

Vapor Barrier |

||||||

|

SONOPIA 2211-F

|

Micro-perforated In ALUPIA221 |

16Kg/㎥ 25mmT Glasswool |

Seamless Tube |

-30℃~+140℃ |

Max 200mmWG |

Max 30m/sec |

10m/carton box |

3~18” (75~450mm) |

SONOPIA2214

Application

Special film for scatter-proof and sound-proof is used. It’s ideal for special facilities property is the same as that of SONOPIA2211. Inner Duct is encapsuled with a very thin OPP or PET film, thus no dust or moisture does not come out the insulation.

Features

In case it is used in humid areas such as bathroom, rest room, etc. The glasswool does not collect moisture. Therefore sound proof property is not increased bacteria, mold and other harmful micro organism can be prevented.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Inner core |

Insulation |

Vapor Barrier |

||||||

|

SONOPIA 2214 |

Micro-perforated In ALUPIA221 |

20mmT Polyester |

Seamless Tube |

-30℃~+140℃ |

Max 200mmWG |

Max 30m/sec |

10m/carton box |

3~18” (75~450mm) |

TAPIA135-T135

Adhesive Strength

Adhesive is not used, but heat-welding manufacture method is used.

Steel Wire

High tensile steel wires are suitable to each size to keep its performance and function perfectly.

Main Material

It’s coated with PVC

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Foil |

Wire |

Adhesion |

||||||

|

TAPIA 135 |

Tarpaulin |

High Steel Wire |

Hot Melting |

-20℃~+80℃ |

Max 350mmWG |

Max 30m/sec |

10m/carton box |

3~40” (75~1000mm) |

ISOPIA-SP

Application

The product is manufactured by inserting clips instead of using adhesive strength and steel wire. This provides the benefit of supporting various materials, durability, and strength against air pressure.

Main Material

Non-ignitable Spunbond

Outer Jacket (Vapor Barrier)

Outer surface is seamless tube-form vapor barrier, therefore, air will never leak out.

|

Technical Data |

Main Materials |

Temperature Range |

Working Pressure |

Air Velocity |

Standard Length |

Diameter Range |

||

|

Inner core |

Insulation |

Vapor Barrier |

||||||

|

ISOPIA-SP

|

Non- Ignitable Spunbond |

16Kg/㎥ 25mmT Glasswool |

Seamless Tube |

-20℃~+80℃ |

Max 200mmWG |

Max 25m/sec |

10m/carton box |

3~18” (75~450mm) |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- DOO HYUN TAE

- Address

- HAENG JIN B/D 53-1 YOUIDO-DONG, YOUNGDEUNGPO-GU, SEOUL, KOREA

- Product Category

- HVAC Systems & Parts,Machinery & Parts

- No. of Total Employees

- 1-50

- Company introduction

-

STC Inspire the world

FLEXIBLE DUCT for Better Air Environment

Greetings

The construction market is changing faster than ever as we enter into 21st century. Customer demands are also changing accordingly.

To properly respond to customer demands, STC has been constantly investing in developing products and in the production process since our founding.

In result, it enabled us to produce and supply the best products and take the lead in the flexible air duct market.

STC will continue to develop and produce the best products that best fits our customer’s needs, and will help the success of our customers businesses.

Thank you!

Doo Hyun Tae

President/CEO

※ Company info

Jan 2011 Changed the company name to SEUNGBO TECH CO.,LTD.

Jan 2010 Enlarged Production Lines

Jun 2008 Built-up a New Factory and Enlarged Facilities

Feb 2006 NANO PROTECT(Germany)

Apr 2005 Equipped with new machines

Feb 2004 Flexible Duct Insulation HANF

Dec 2002 Purchased new machines from F.D

Oct 2002 APIRO.SA(Switzerland)

Jan 2002 Changed the company name to STC Korea co.

Jun 2000 Set up a new factory

Mar 1997 ROTHENBERGER

Jan 1997 Acquired FILK Certification

Jun 1996 Launched Kyungmi Flexible Co.

- Main Markets

-

Japan

Japan

- Main Product