rubber peptizer

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- RUIJIE

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Catalyst & Chemical Auxiliaries , Organic Salt

Liaocheng Ruijie Chemical Co.,LTD

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

15

| Product name | rubber peptizer | Certification | - |

|---|---|---|---|

| Category |

Catalyst & Chemical Auxiliaries

Organic Salt |

Ingredients | - |

| Keyword | rubber auxiliary , rubber peptizer , rubber plasticizer a | Unit Size | - |

| Brand name | RUIJIE | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

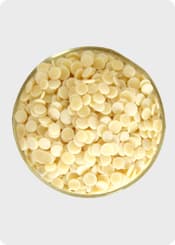

This products are mixtures of zinc saturation fatty acid and zinc unsaturation fatty acid, It is nontoxic, hardly soluble in most organic solvents except alkyl halid, in mineral oil and lipin, and not soluble in water.

Product specification:

|

Item |

Rubber plasticizer A |

|

Appearance |

yellowish pastilles |

|

Melting point(℃) |

98-108 |

|

Zn Oxide content(%) |

12-14 |

|

Ash content(%) |

12-14 |

|

Iodine value (gI2/100g) |

40-50 |

Note: 1:some physical and chemical properties can be adjusted to client request accordingly.2: The test result complies with the RoHS directives 2002/95/EC and its subsequent amendments)

Packaging: 25 Kg N.W. per sack.

Storage: Stored in dry and cool places.

Shelf life: 6 months.

Applications:

It is one muti-functional processing additive for rubber products, suitable in the internal mixers for both natural rubber and synthetic rubber such as BR,SBR,NBR,EPDM.When used as the additive for extrusion, it can improve the die swell ratio and the quality of final products ,and reduce the temperature of extruding process.

It is of excellent compatibility with rubber compound, makes the rubber compound with more plasticity and fluidity without blooming,can improve the elasticity and anti-tear strength of Sulfur Colloid ,lower the temperature, shorten the cycle in the mixing or plasticizing process,showing good effect on the improving of measure stability and yield, no bad effect on the bonding between metal and fiber.

Dosage:2-5phr, may be punched when plasticizing the raw rubber or punched with other additives at the first phase of mixing process.( for multistage mixing process it can be added after carbon black filling).

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Zhangxianming

- Address

- NO.159dongchangdong road development zone

- Product Category

- Industrial Supplies

- No. of Total Employees

- 51-100

- Company introduction

-

RUBBER&PLASTIC AUXILIARYS, SYNTHETIC ESTER, SYNTHEITIC ESTER BASE OIL MANUFACTURER

- Main Product