BOPP FILM (Biaxially Oriented Polypropylene FILM)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Plastic Film

Filmax Corporation

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | BOPP FILM (Biaxially Oriented Polypropylene FILM) | Certification | - |

|---|---|---|---|

| Category | Plastic Film | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

BOPP

BOPP FILM (Biaxially Oriented Polypropylene FILM)

This polypropylene based film utilized biaxial orientation technology-machine direction and transverse direction-which offers the best optical characteristics and mechanical strength. It is widely used for packaging foods and laminating.

| BOPP Film for general purpose

| Film Type | Thickness (microns) |

Yield (m2/Kg) |

Sealability | Treatment | Description |

|

BG |

20 | 55.6 | X | O |

For general printing and laminating |

| 30 | 37.0 | X | O | ||

|

BG-R |

20 | 55.6 | X | O |

For general printing and cold-seal |

| 30 | 37.0 | X | O | ||

|

BG-T |

30 | 37.0 | X | O |

For fabric,accessory,envelope |

| 40 | 27.8 | X | O | ||

|

BT |

30 | 37.0 | X | B |

For industrial adhesive tapes |

| 40 | 27.8 | X | B | ||

|

BT-H |

25 | 44.4 | X | B |

For high clarity adhesive tapes |

| BOPP Film for laminating

| Film Type | Thickness (microns) |

Yield (m2/Kg) |

Sealability | Treatment | Description |

|

LF |

12 | 92.6 | X | B |

Glossy laminating for book cover,shopping bag,poster |

| 15 | 74.1 | X | B | ||

|

DF |

15 | 74.1 | X | B |

Dull laminating for book cover,shopping bag,poster |

| BOPP Film for Anti-fogging

| Film Type | Thickness (microns) |

Yield (m2/Kg) |

Sealability | Treatment | Description |

|

BG-F |

22 | 50.5 | X | O |

For vegetable and fruit packaging |

| 27 | 41.2 | X | O | ||

| AFO | 32 | 34.7 | O | B | Sealable anti-fogging film |

| BOPP Film for Heat-sealing

| Film Type | Thickness (microns) |

Yield (m2/Kg) |

Sealability | Treatment | Description |

|

SG |

20 | 55.6 | O | O |

Mostly used heat sealable film |

| 30 | 37.0 | O | O | ||

| 40 | 27.8 | O | O | ||

|

SG-â ¡ |

21 | 52.9 | O | N |

For cigarette packaging |

| 23 | 48.3 | O | N | ||

| SO | 25 | 44.4 | O | O | One side heat sealable film |

|

SL |

20 | 55.6 | O | O |

Low temperature heat sealable film |

| 30 | 37.0 | O | O | ||

|

SX |

20 | 55.6 | O | O |

Low shrink film for audio, video, cassette and CD packaging |

| 25 | 44.4 | O | O | ||

|

SC |

21 | 52.9 | O | N |

For cigarette packaging |

| 23 | 48.3 | O | N | ||

|

SSC |

21 | 52.9 | O | N |

Low shrink film for cigarette packaging |

| 23 | 48.3 | O | N | ||

| SOC | 20 | 55.6 | O | N | Low shrink film for cigarette packaging |

| SG-S | 18 | 61.7 | O | O | For straw packaging |

| White colored BOPP Film

| Film Type | Thickness (microns) |

Yield (m2/Kg) |

Sealability | Treatment | Description |

| WG | 30 | 51.3 | X | B | White opaque film for label and soap packaging |

|

WO |

30 | 51.3 | O | O |

One side heat sealable white opaque film |

| 40 | 38.5 | O | O | ||

|

FG |

30 | 51.3 | X | B |

Pearl film |

| 40 | 38.5 | X | B | ||

|

FS |

30 | 51.3 | O | O |

Heat sealable pearl film |

| 40 | 38.5 | O | O |

| Film Type | Thickness (microns) |

Yield (m2/Kg) |

Sealability | Treatment | Description |

| WL | 80 | 16.7 | X | B | Synthetic Paper |

| Functional BOPP Film

| Film Type | Thickness (microns) |

Yield (m2/Kg) |

Sealability | Treatment | Description |

| SF | 15 | 74.1 | X | B | Sanitary finished film for paper lamination |

| BF | 15 | 74.1 | O | B | Breathable film for fresh produce |

- Sealability : O(Heat Sealable) X(Non Heat Sealable)

- Treatment : X(No Treatment) O(One side Treatment) B(Both side Treatment)

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Young-shik Hong

- Address

- 261, Gongdan-dong, Gumi-si, Gyeongsangbuk-do

- Product Category

- Capacitors

- Company introduction

-

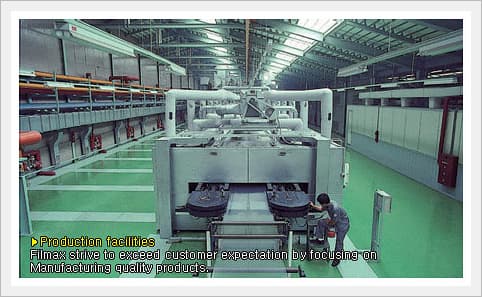

FILMAX is a professional company specializing in manufacturing films for wrapping purposes.

We first began operations in June 2003, founded on P&A methods adopted from the former SUTTONG Film business. It is both a privilege and an honor to offer our high quality products renowned for convenience and hygiene.The highest priority of our company is to manufacture products that are human-oriented and environmentally friendly, thus furthering our company's aspirations to serve better society as a whole. Our Research Instituteoffer of FILMAX has developed and manufactured some of the finest, environment-friendly wrapping products that meet and serve various needs and functions with their distinct features and qualities.

As well, we aspire to ofer the most comprehensive customer service in the industry to exceed the expectations of our customers. That's because FILMAX strives to be a global leader in the industry. By maintaining customer satisfaction, maximizing in manufacturing and operation efficiency and diversifying our product line, we have established an appreciable riche in the global market.

- Main Markets

-

Australia

Australia

France

France

Germany

Germany

Japan

Japan

U.S.A

U.S.A

- Main Product