Epoxy Resin

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Chemicals

Seppong Polymer Co., Ltd.

- Verified Certificate

-

17

| Product name | Epoxy Resin | Certification | - |

|---|---|---|---|

| Category | Other Chemicals | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

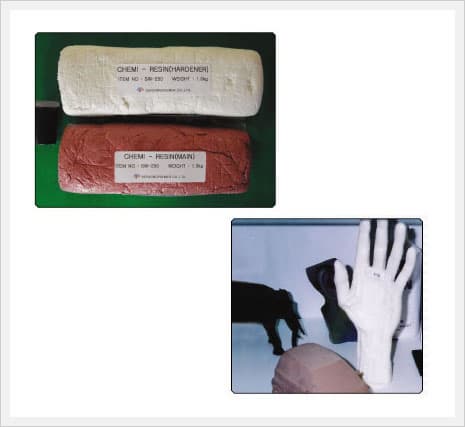

Workable Resin

The resin is easy workable owing to light weight like wood and less abrasion and normally applied to manufacture master model and/or inspecting gauge.

SW - 150

|

Characteristics |

Good strength, Easy to mix, Easy machine processing,Good hand processing |

|

|

Usage |

For JIG productions such as C/F, Model production |

|

|

Packing |

Main material |

1kg x 15EA / 1BOX |

|

Hardener |

||

SW - 250

|

Characteristics |

Easy to mix, Easy machine processing, Good hand processing |

|

|

Usage |

Applied for master model, Easy to hand, Adhere to car audio,Model production |

|

|

Packing |

Main material |

1kg x 10EA / 1BOX |

|

Hardener |

||

Design Model Resin

This low specific gravity product is excellent in manual working, so it is used for designing.

SW - 350

|

Characteristics |

Low gravity, Excellent hand processing |

|

|

Usage |

Design model, Model production |

|

|

Packing |

Main material |

1kg x 7EA / 1BOX |

|

Hardener |

||

Back up & Base Resin

It shows good workability and adhesiveness for repairs as a modeling paste and apparent back up resin.

SB - 050

|

Characteristics |

High strength, Base level, Easy reinforcing and bonding |

|

|

Usage |

Adhesive base level, |

|

|

Packing |

Main material |

1kg x 20EA / 1BOX |

|

Hardener |

||

SL - 354

|

Characteristics |

Low gravity, high strength, Easy to Verticality and horizontality processing |

|

|

Usage |

Surface enforcing (contains chop), easy accumulating on rear side, excellent strength |

|

|

Packing |

Main material |

1kg x 15EA / 1BOX |

|

Hardener |

||

SB - 060

|

Characteristics |

Excellent Heat resistance ( Contain aluminum powder ) |

|

|

Usage |

Simplicity mold, Vacuum forming mold, Foaming mold |

|

|

Packing |

Main material |

1kg x 20EA / 1BOX |

|

Hardener |

||

Laminating Resin

Easily combined with yarn cloth, silica and powdered metals and can have good dimensional stability and mechanical strength.

SL - 300

|

Characteristics |

Metal powder, Glass fiber, Good impregnation, Easy make FRP Mold |

|

|

Usage |

General laminating |

|

|

Packing |

Main material |

20kg x 1EA / 1CAN |

|

Hardener |

4kg x 1EA / 1EA |

|

SL - 360

|

Characteristics |

Contain Glass fiber (Chop) |

|

|

Usage |

Heat resistance, reinforce the reverse (Vacuum, Foaming mold) |

|

|

Packing |

Main material |

20kg x 1EA / 1CAN |

|

Hardener |

4kg x 1EA / 1EA |

|

Gel - Coat Resin

Gel-coat resin is used to reinforce the resinous surface and does not fall while securing uniform thickness when it is vertically applied.

SP - 404 (BLUE)

|

Characteristics |

Keep high hardness, Abrasion resistance, Low contraction |

|

|

Usage |

Manufacture Resin mold, Surface resin |

|

|

Packing |

Main material |

10kg x 1EA / 1CAN |

|

Hardener |

1kg x 1EA / 1EA |

|

SP - 410 (WHITE)

|

Characteristics |

Keep middle hardness |

|

|

Usage |

General resin mold, Testing tools |

|

|

Packing |

Main material |

10kg x 1EA / 1CAN |

|

Hardener |

1kg x 1EA / 1EA |

|

SP - 460 (GREY)

|

Characteristics |

Excellent heat resistance, Little size variant |

|

|

Usage |

Vacuum foaming mold, Vacuum forming mold |

|

|

Packing |

Main material |

10kg x 1EA / 1CAN |

|

Hardener |

1kg x 1EA / 1EA |

|

Casting Resin

Can have good mechanical strength and dimensional stability of a cast after being hardened owing to easy insertion and less heat shrink.

SC - 500 (BLUE, BLACK)

|

Characteristics |

Middle viscosity, High strength |

|

|

Usage |

Muti-purpose casting system, Base , N/C |

|

|

Packing |

Main material |

10kg x 1EA / 1CAN |

|

Hardener |

1kg x 1EA / 1EA |

|

SC - 510 (GREEN)

|

Characteristics |

Middle viscosity, High strength, Easy used sheet metal forming Tool |

|

|

Usage |

Used make Pulp Mold |

|

|

Packing |

Main material |

10kg x 1EA / 1CAN |

|

Hardener |

1kg x 1EA / 1EA |

|

SC - 560 (GREY)

|

Characteristics |

Heat resistance, Chemical resistance |

|

|

Usage |

Vacuum forming mold, foaming mold |

|

|

Packing |

Main material |

10kg x 1EA / 1CAN |

|

Hardener |

1kg x 1EA / 1EA |

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- KIM, JONG-MAN

- Address

- #320 Mario Tower, 222-12, Guro-3dong,, Guro-guSeoul,

- Product Category

- Other Plastic Raw Materials

- No. of Total Employees

- 101-500

- Company introduction

-

We, Sepoong Polymer was established in the year 1987. We manufacture and sale ABS Board, Rod, Acryl Board, PU & Epoxy modeling and tooling board, Various Modeling pastes, Urethane Foam for mock-up, master model, checking-fixture, design model in the electric & electronic fields and car, ship, airplane industry. We will go far toward developing a basic industry as a leading material petrochemicals distribution company, promise to do all our efforts to elevate welfare work. We will go forth as a service and confidential company. Now, Sepoong Polymer Co., Ltd. go into leap to the future. Going to meet new millennium, we make a steady company with unlimited ability and latent energy.

- Main Markets

-

Malaysia

Malaysia

Singapore

Singapore

Thailand

Thailand

- Factory Information

-

Sepoong Polymer

- Main Product

South Korea

South Korea

_2.jpg)